Fluororubber microcellular foam material and preparation method thereof

A microcellular foaming material and fluororubber technology, which is applied in the field of fluororubber microcellular foaming material and its preparation, can solve the problems such as no literature reports on fluororubber foaming formula and process, and less research and development of fluororubber foaming products, etc. Achieve the effect of good oil resistance and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

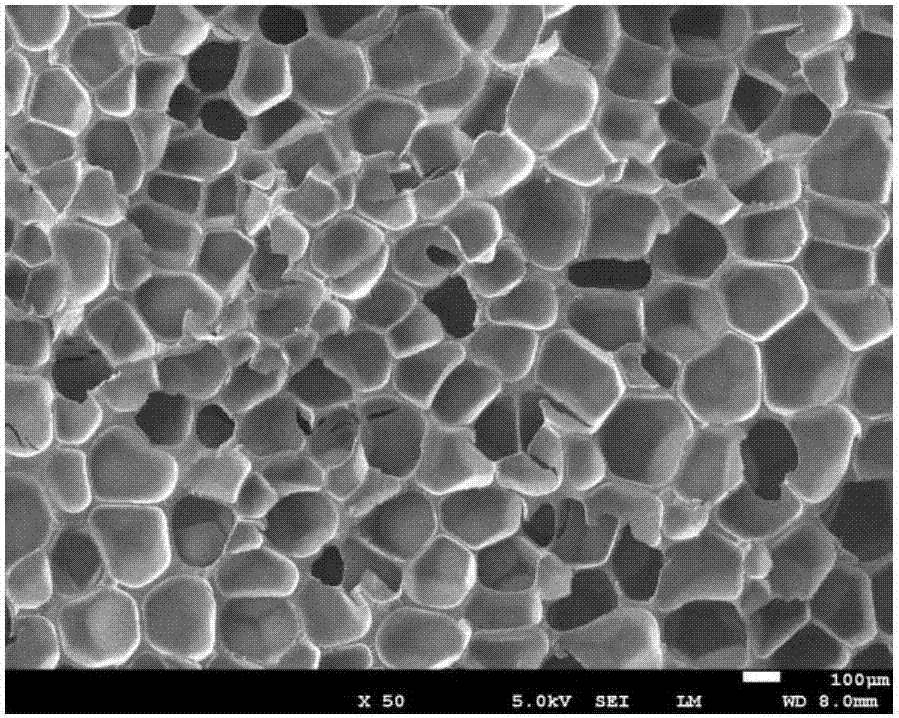

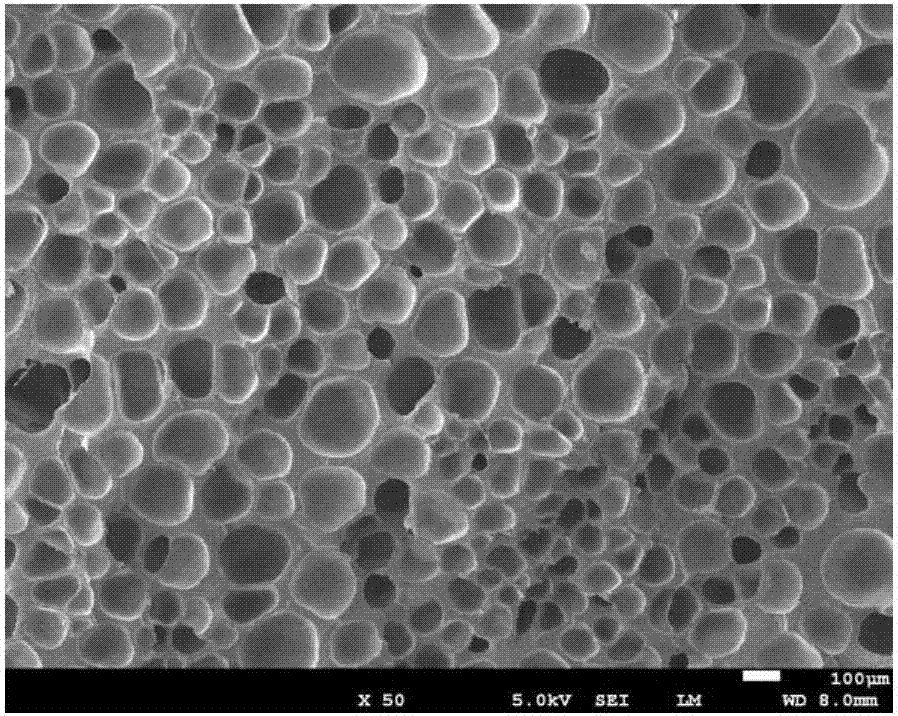

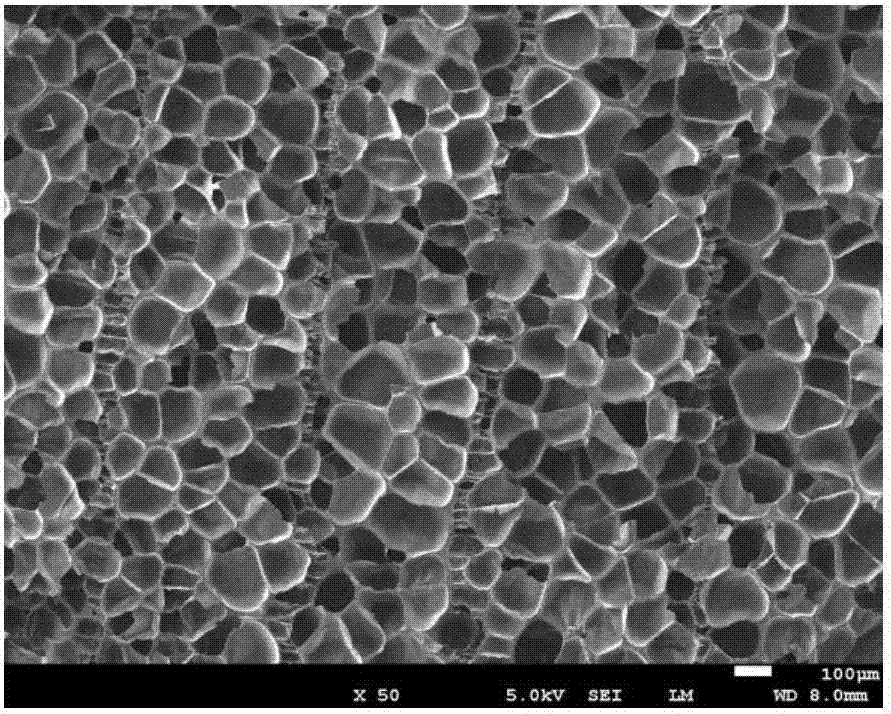

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment:

[0032] 1) Compound rubber preparation

[0033] (1) The temperature of the internal mixer is set to 60-90°C, and the rotational speed is 40-60rpm. First, put the fluororubber into the internal mixer, masticate for 60s, lift the weight, add processing aids and acid absorbers, and mix for 90s , lift the weight, put in fillers and modifiers, continue mixing for 90s, then remove the glue and release the film to obtain the fluororubber masterbatch;

[0034] (2) Raise the temperature of the rollers of the mill to 40-50°C, adjust the roller distance to 2 mm, put the masterbatch into the mill, knead for 3-4 minutes, then add vulcanizing agent and accelerator, and thin pass 3-4 times , make a triangular bag 3 times, and turn it around at 90°, and finally adjust the roller distance to about 8-10mm to place the film, cool to room temperature, and put it for 24 hours for use.

[0035] 2) Pre-vu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com