Bilateral laser scanning and welding method of T-shaped connector

A laser scanning and welding method technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of unstable droplet transfer, difficult wire filling, etc., and achieve convenient welding process, easy mechanical automation, and reduced precision. Demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

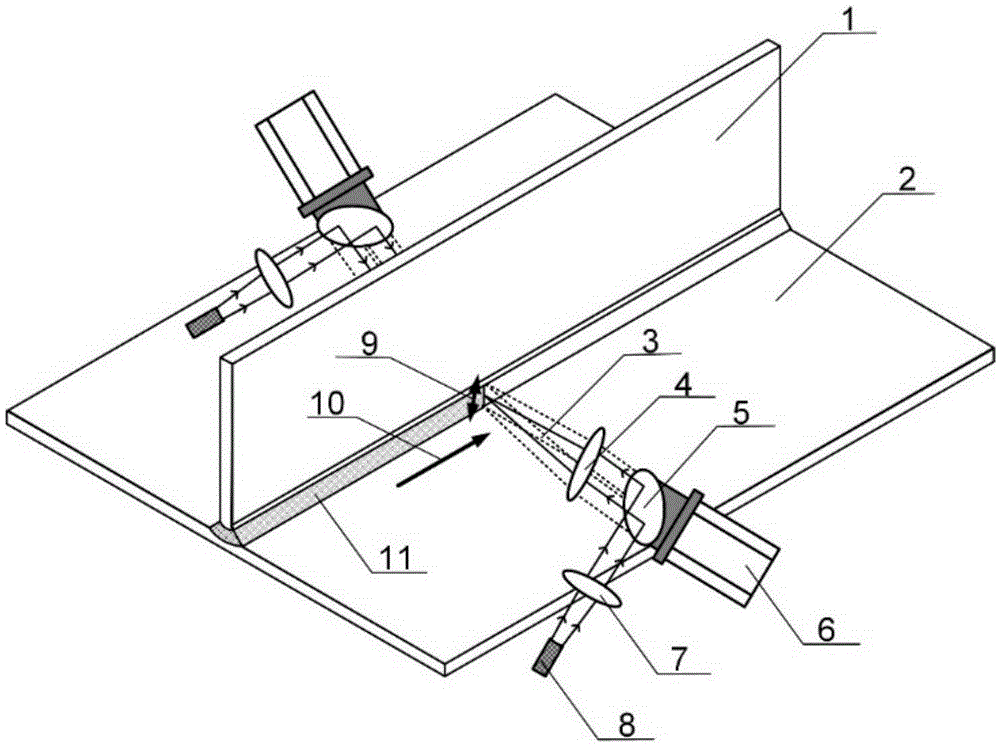

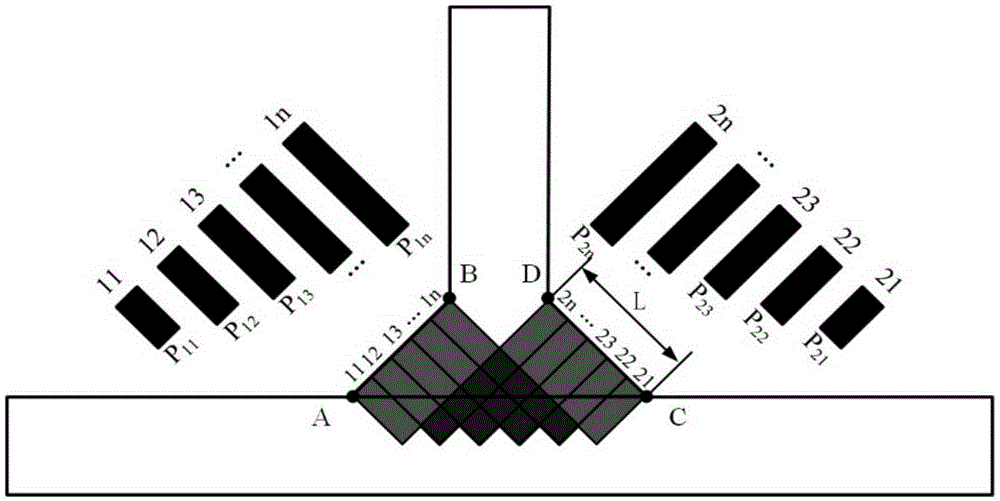

[0029] Specific embodiment one: A kind of T-joint double-sided laser scanning welding method of this embodiment is carried out according to the following steps:

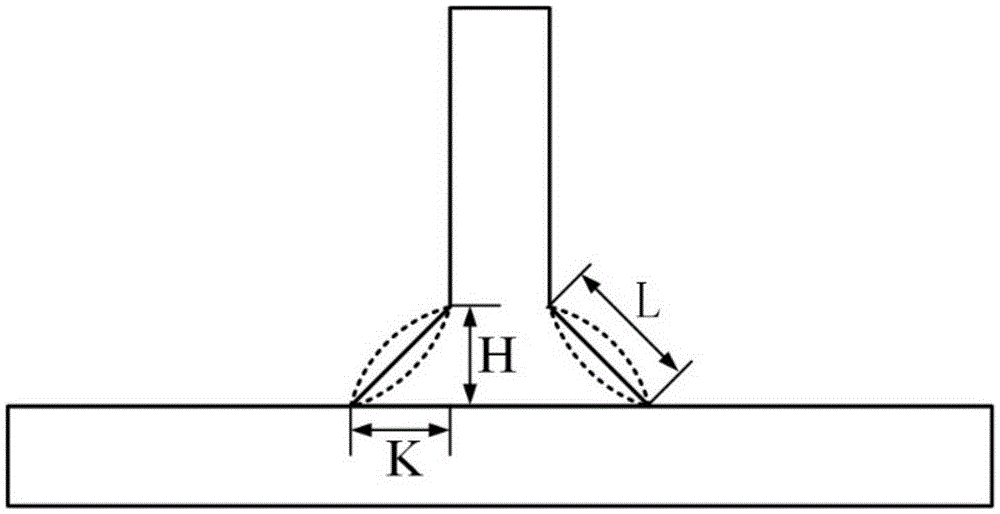

[0030] 1. Determine the size K / H of the welding leg: determine the different welding leg size K / H according to the thickness of the stringer vertical plate and the skin plate and the actual demand of the weld seam. The said welding leg size K / H is 1 to 2.5 ;

[0031] 2. Process the stringer vertical plate: process the stringer vertical plate into an integrated structural plate composed of the upper straight plate and the bottom quadrangular prism; the cross section of the bottom quadrangular prism is isosceles trapezoidal, and the thickness of the stringer vertical plate is D 1Equal to the length of the upper base of the isosceles trapezoid where the quadrangular prism at the bottom is located; where the solder leg size K described in step 1 is equal to half the difference between the upper base length and the lower ...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that: the solder fillet size K / H in step 1 is 1.5-2. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the scan width described in step 4 is 1 mm to 15 mm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com