Air supply brick and preparation method thereof

A technology for supplying air bricks and air chambers is applied in the field of refractory materials for iron and steel smelting, and can solve the problems of pollution, scrapping, deformation of the bottom plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

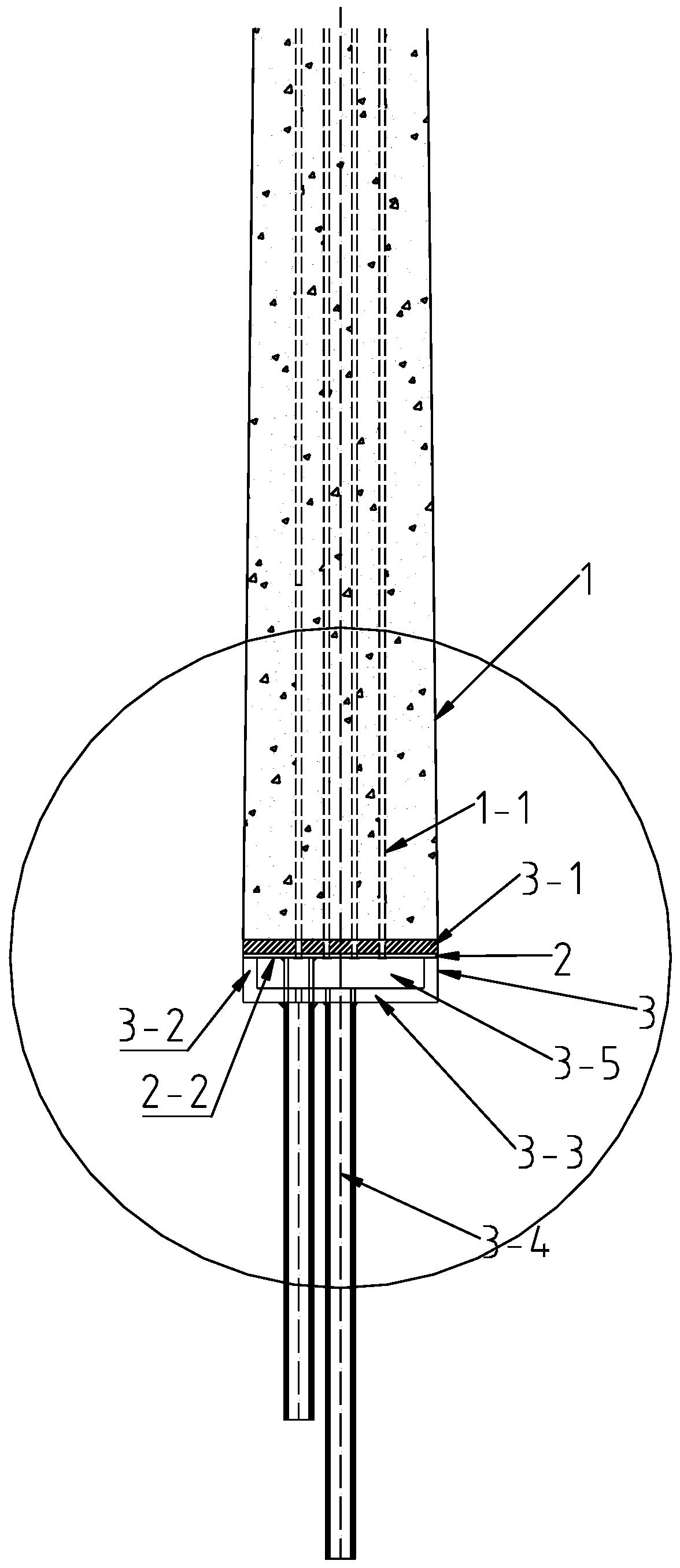

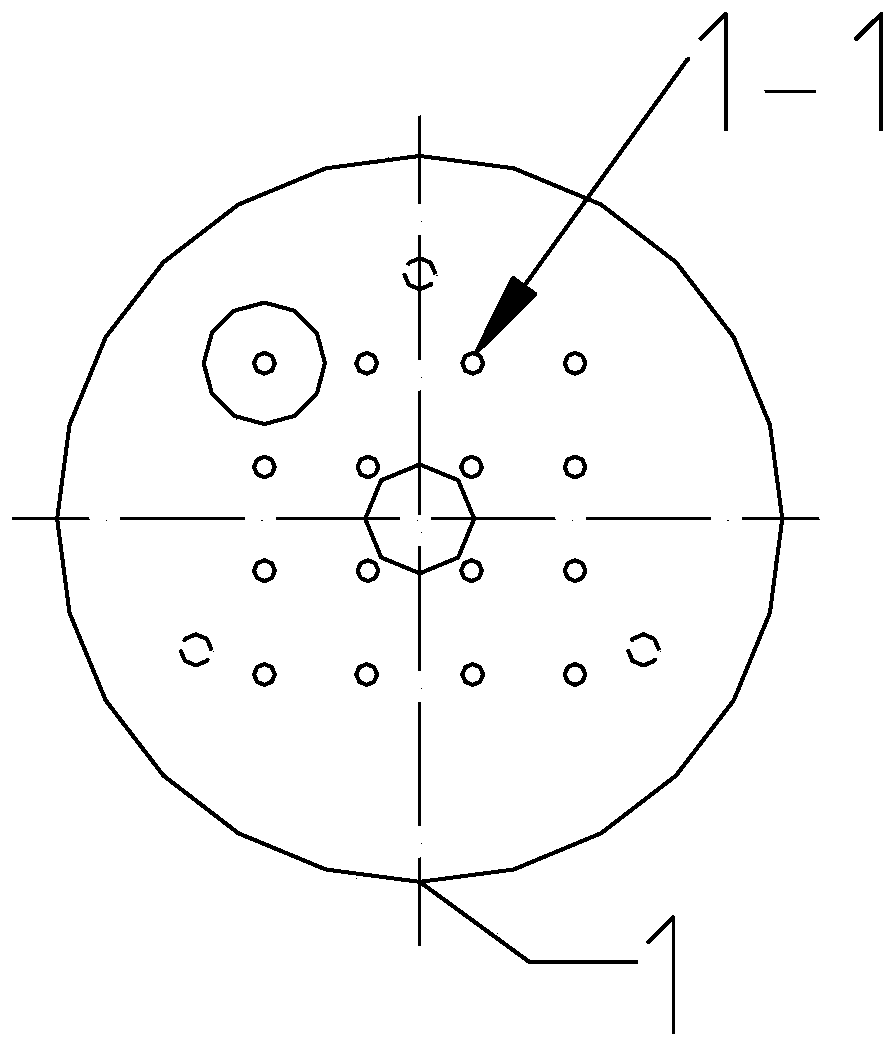

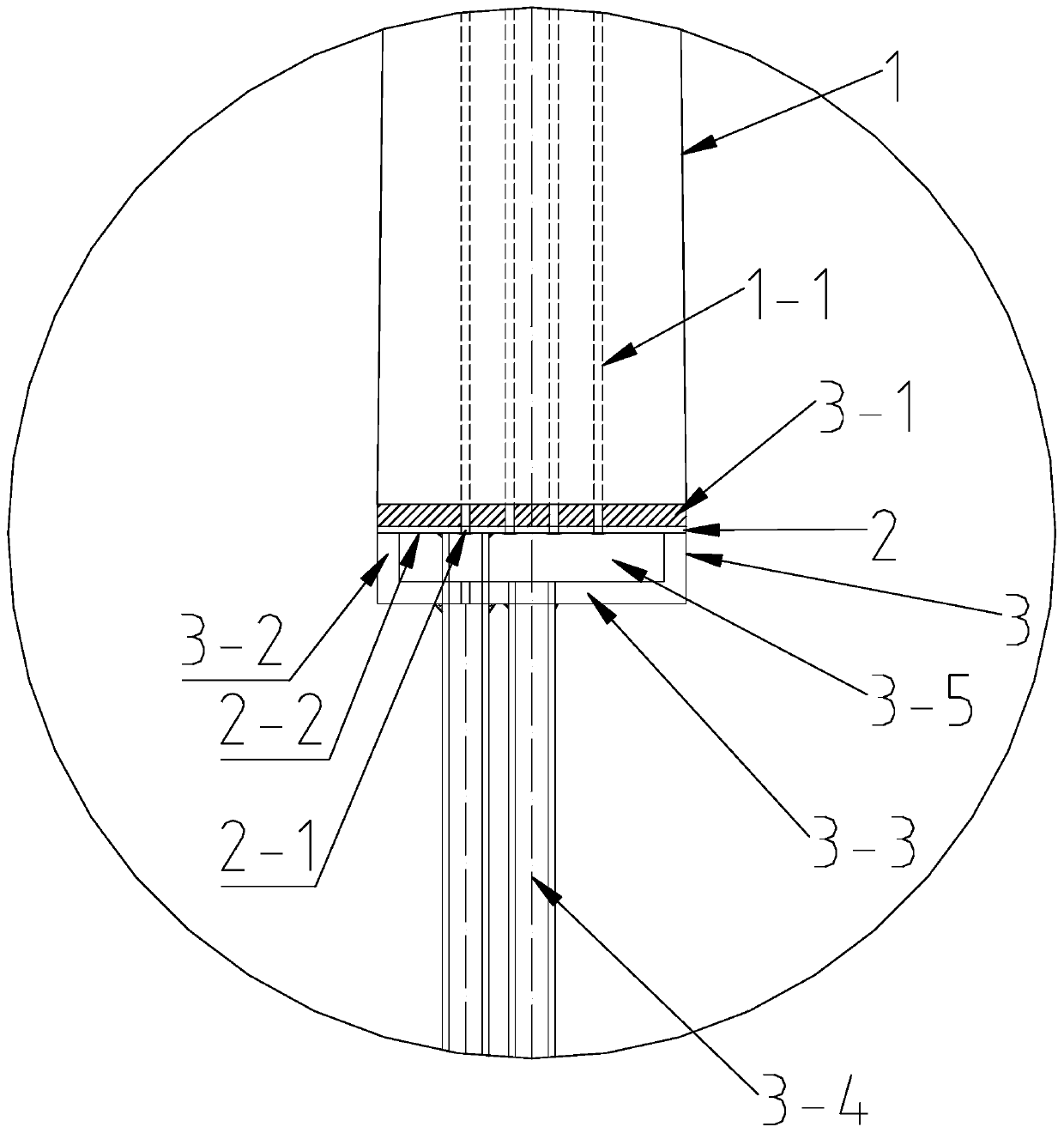

[0037] Such as figure 1 with image 3As shown, the gas supply brick of this embodiment includes a gas supply brick body 1 and an air chamber 3, and the first end of the stainless steel metal ventilation pipe 1-1 in the gas supply brick body 1 protrudes to the gas supply brick body 1 outside, and extend into the bottom plate hole on the air chamber bottom plate 3-1 of the air chamber 3, the pipe wall of the stainless steel metal ventilation pipe 1-1 and the hole wall of the bottom plate hole are argon arc welding Welding connection; a stainless steel bottom plate 2 is installed between the air chamber bottom plate 3-1 and the inner cavity 3-5 of the air chamber 3, and the stainless steel bottom plate 2 is provided with a drilling hole 2-1; the stainless steel metal The first end of the ventilation pipe 1-1 protrudes from the air supply brick body 1 and passes through the bottom plate hole and the drill hole 2-1 in sequence, and the pipe wall of the stainless steel metal venti...

Embodiment 2

[0048] Such as figure 1 with image 3 As shown, the gas supply brick of this embodiment includes a gas supply brick body 1 and an air chamber 3, and the first end of the stainless steel metal ventilation pipe 1-1 in the gas supply brick body 1 protrudes to the gas supply brick body 1 outside, and extend into the bottom plate hole on the air chamber bottom plate 3-1 of the air chamber 3, the pipe wall of the stainless steel metal ventilation pipe 1-1 and the hole wall of the bottom plate hole are argon arc welding Welding connection; a stainless steel bottom plate 2 is installed between the air chamber bottom plate 3-1 and the inner cavity 3-5 of the air chamber 3, and the stainless steel bottom plate 2 is provided with a drilling hole 2-1; the stainless steel metal The first end of the ventilation pipe 1-1 protrudes from the air supply brick body 1 and passes through the bottom plate hole and the drill hole 2-1 in sequence, and the pipe wall of the stainless steel metal vent...

Embodiment 3

[0059] Such as figure 1 with image 3 As shown, the gas supply brick of this embodiment includes a gas supply brick body 1 and an air chamber 3, and the first end of the stainless steel metal ventilation pipe 1-1 in the gas supply brick body 1 protrudes to the gas supply brick body 1 outside, and extend into the bottom plate hole on the air chamber bottom plate 3-1 of the air chamber 3, the pipe wall of the stainless steel metal ventilation pipe 1-1 and the hole wall of the bottom plate hole are argon arc welding Welding connection; a stainless steel bottom plate 2 is installed between the air chamber bottom plate 3-1 and the inner cavity 3-5 of the air chamber 3, and the stainless steel bottom plate 2 is provided with a drilling hole 2-1; the stainless steel metal The first end of the ventilation pipe 1-1 protrudes from the air supply brick body 1 and passes through the bottom plate hole and the drill hole 2-1 in sequence, and the pipe wall of the stainless steel metal vent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com