Preparation method of high-purity silicon nitride powder

A silicon nitride powder, high-purity technology, applied in the field of high-purity silicon nitride powder preparation, can solve the problems of low product purity, poor particle size uniformity, and high cost, achieve uniform particle size, refine particle size, improve The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing high-purity silicon nitride powder, comprising the following steps:

[0023] Weighing raw materials: Weigh water-soluble starch and silicon dioxide powder respectively according to the weight ratio of water-soluble starch: silicon dioxide powder = 0.8~1.2:1, then weigh nano-silicon nitride sintering aid, the amount of sintering aid It is 1-3wt% of the sum of the mass of water-soluble starch, silica powder and sintering aid; among them, the particle size of silica powder is 0.8-1.2μm, and the purity is 99.99%; the carbon content of water-soluble starch The particle size of the sintering aid is 0.8-2.0nm, and the purity is 99%.

[0024] Mixing: Disperse the water-soluble starch in water, heat it to 80°C, and keep it warm for 45 minutes to make the water-soluble starch gelatinize evenly to obtain a gelatinized product; cool the gelatinized product to 50°C, and then add silicon dioxide powder and sintering aid Add it to the gel...

Embodiment 1

[0029] Disperse 29.85g of water-soluble starch in 100mL of water, heat it to 80°C, and keep it warm for 45min to make it gelatinize into a uniform gelatinized product, cool the gelatinized product to 50°C, and then add 18.65g of carbon dioxide The silicon powder and 1.5 g of silicon nitride powder with a particle size of 1 nm were stirred for 24 hours to fully mix the three, and then filtered, dried, and sieved to obtain a uniformly mixed precursor powder.

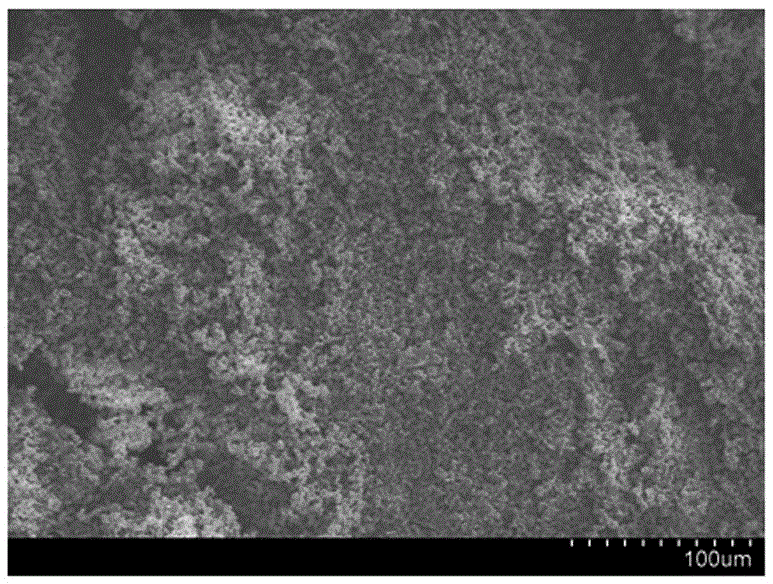

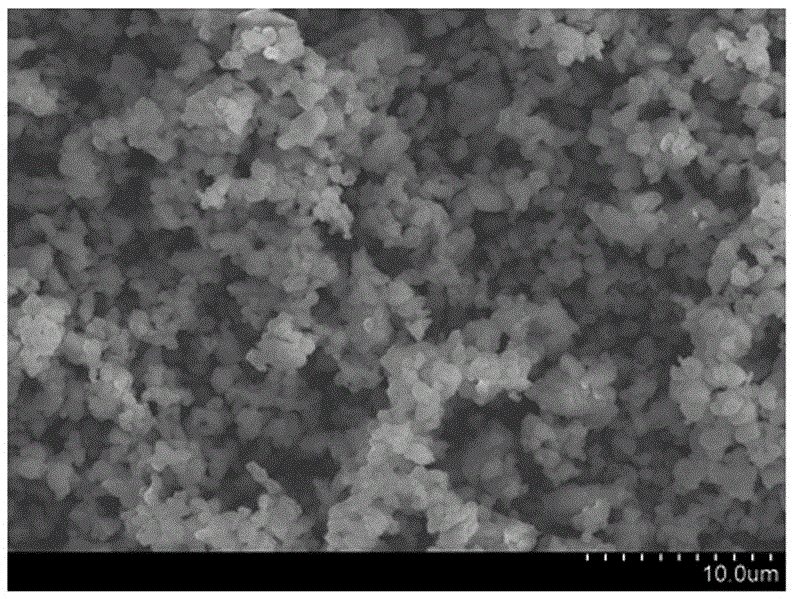

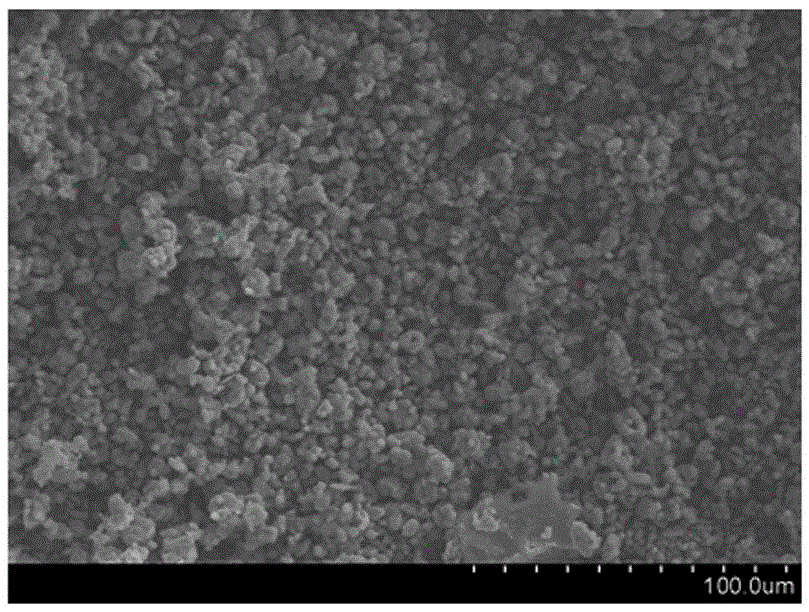

[0030] The precursor powder is put into the reaction furnace, and the ammonia / hydrogen mixed gas is introduced after vacuum treatment, the volume percentage of hydrogen in the mixed gas is 40%, the flow rate of the mixed gas is 2.0L / min, and the reaction temperature is 1350°C. Reaction time 5h. The obtained sintered product was placed in a decarburization furnace, and air was introduced at a flow rate of 10 L / min, and kept for 2 hours to obtain gray high-purity silicon nitride powder. The nitrogen content in the synthesiz...

Embodiment 2~8、 comparative example 1

[0032] With reference to the preparation method of Example 1, change the weight ratio of water-soluble starch to silicon dioxide powder (abbreviated as weight ratio in the table), the particle diameter and the consumption of sintering aid, prepare silicon nitride powder, comparative example 1 uses fluorine Calcium oxide is used as a sintering aid to prepare silicon nitride powder. The obtained silicon nitride powder was tested for elements and particle size, and the results are shown in Table 1.

[0033] Table 1:

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com