High-extensibility packaging film, production method and external package

A production method and packaging film technology, applied in the field of packaging materials, can solve the problems of low tensile resistance, poor ductility, inedibility, etc., achieve the effects of reducing oxygen and moisture, improving ductility, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

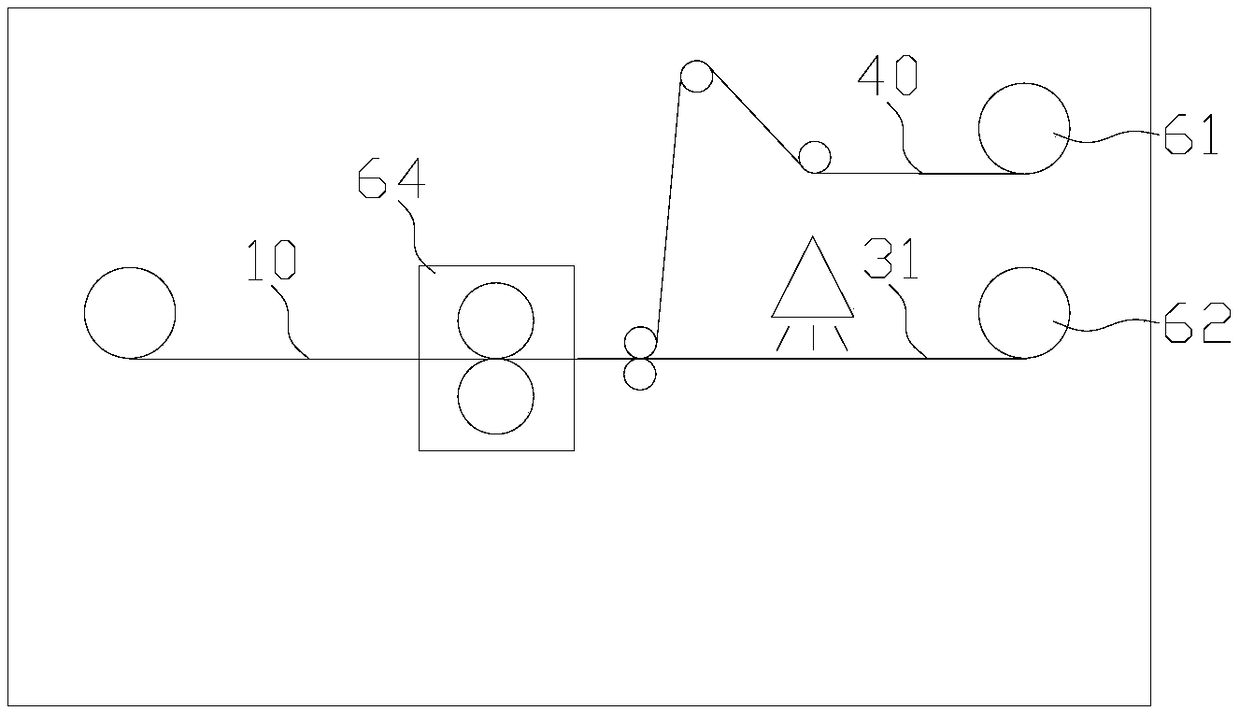

[0043] see Figure 1 to Figure 2 , the present embodiment provides the production method of high-stretch packaging film 1, comprises the following steps:

[0044] (1) Preparation materials: including the upper surface film material, the middle layer coil material and the heat seal layer film material; the upper surface film material is nylon or modified nylon film, and the thickness of the upper surface film material is 1-30 μm; heat sealing The film material of the layer is polypropylene or modified polypropylene film, and the thickness of the film material of the heat-sealing layer is 50-120 μm; 1-30μm;

[0045] (2) Pretreatment of the upper surface film material: corona treatment is carried out on the outer surface of the upper surface film 40, and the roll is harvested as an upper surface coil material for subsequent use;

[0046] (3) Pretreatment of the heat-sealing layer film material: corona treatment is performed on the outer surface of the heat-sealing layer film 20...

Embodiment 2

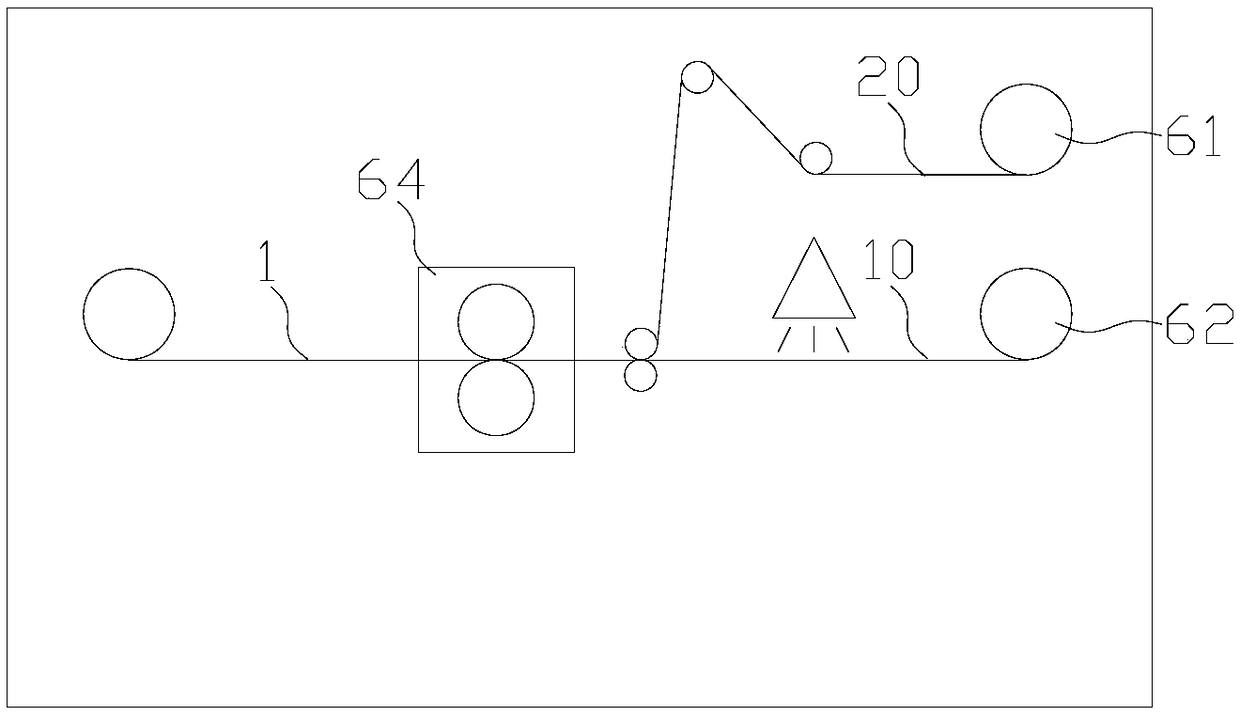

[0053] This embodiment serves as an improvement of the embodiment, and this embodiment provides a production method for a high-stretch packaging film 1, including the following steps:

[0054] (1) Preparation materials: including the upper surface film material, the middle layer coil material and the heat seal layer film material; the upper surface film material is nylon or modified nylon film, and the thickness of the upper surface film material is 1-30 μm; heat sealing The film material of the layer is polypropylene or modified polypropylene film, and the thickness of the film material of the heat-sealing layer is 50-120 μm; 1-30μm;

[0055] (2) Pretreatment of the upper surface film material: corona treatment is carried out on the outer surface of the upper surface film 40, and the roll is harvested as an upper surface coil material for subsequent use;

[0056] (3) Pretreatment of the heat-sealing layer film material: corona treatment is performed on the outer surface of t...

Embodiment 3

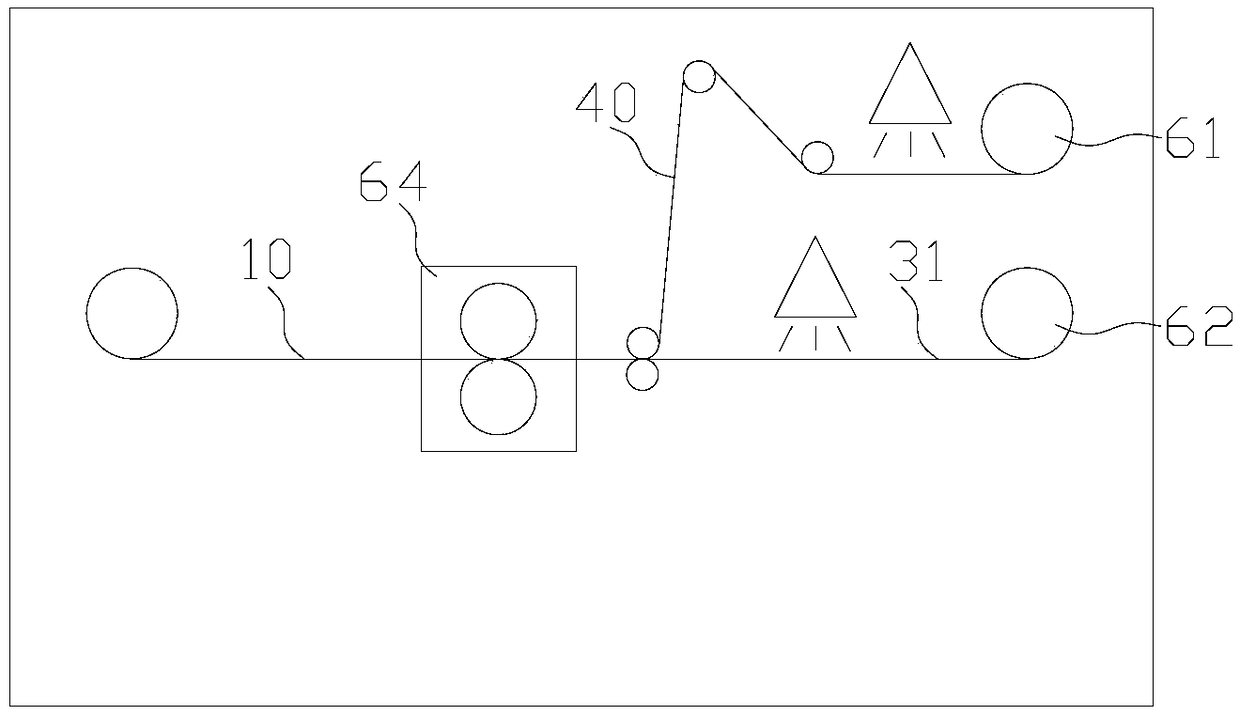

[0062] This embodiment serves as an improvement of the embodiment, and this embodiment provides a production method for a high-stretch packaging film 1, including the following steps:

[0063] (1) Preparation materials: including the upper surface film material, the middle layer coil material and the heat seal layer film material; the upper surface film material is nylon or modified nylon film, and the thickness of the upper surface film material is 1-30 μm; heat sealing The film material of the layer is polypropylene or modified polypropylene film, and the thickness of the film material of the heat-sealing layer is 50-120 μm; 1-30μm;

[0064] (2) Pretreatment of the upper surface film material: corona treatment is carried out on the outer surface of the upper surface film 40, and the roll is harvested as an upper surface coil material for subsequent use;

[0065] (3) Pretreatment of the heat-sealing layer film material: corona treatment is performed on the outer surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com