Production method of silicon carbide micro-reactor based on gel molding

A micro-reactor, silicon carbide technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical processes, etc. and other problems, to achieve the effect of improving strength, high green strength and reducing free silicon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

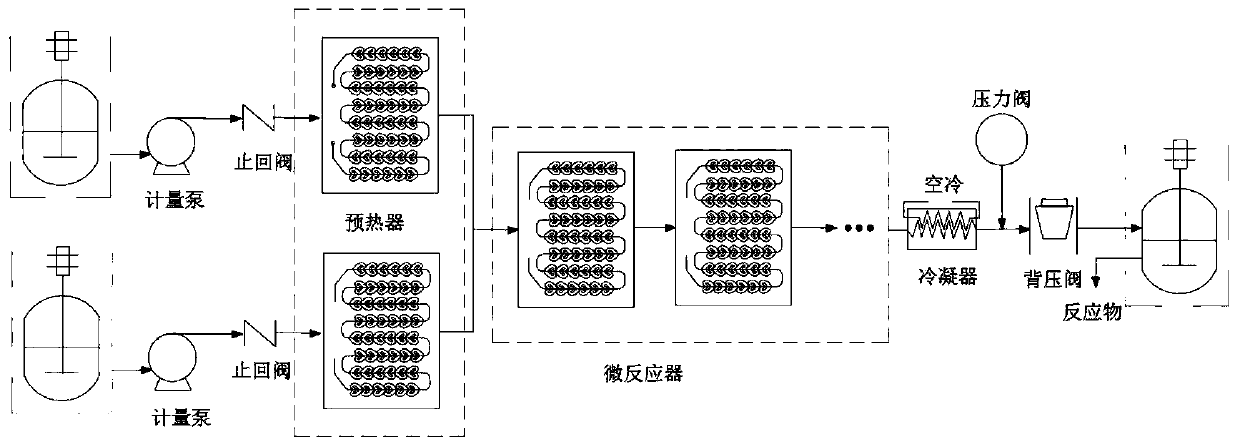

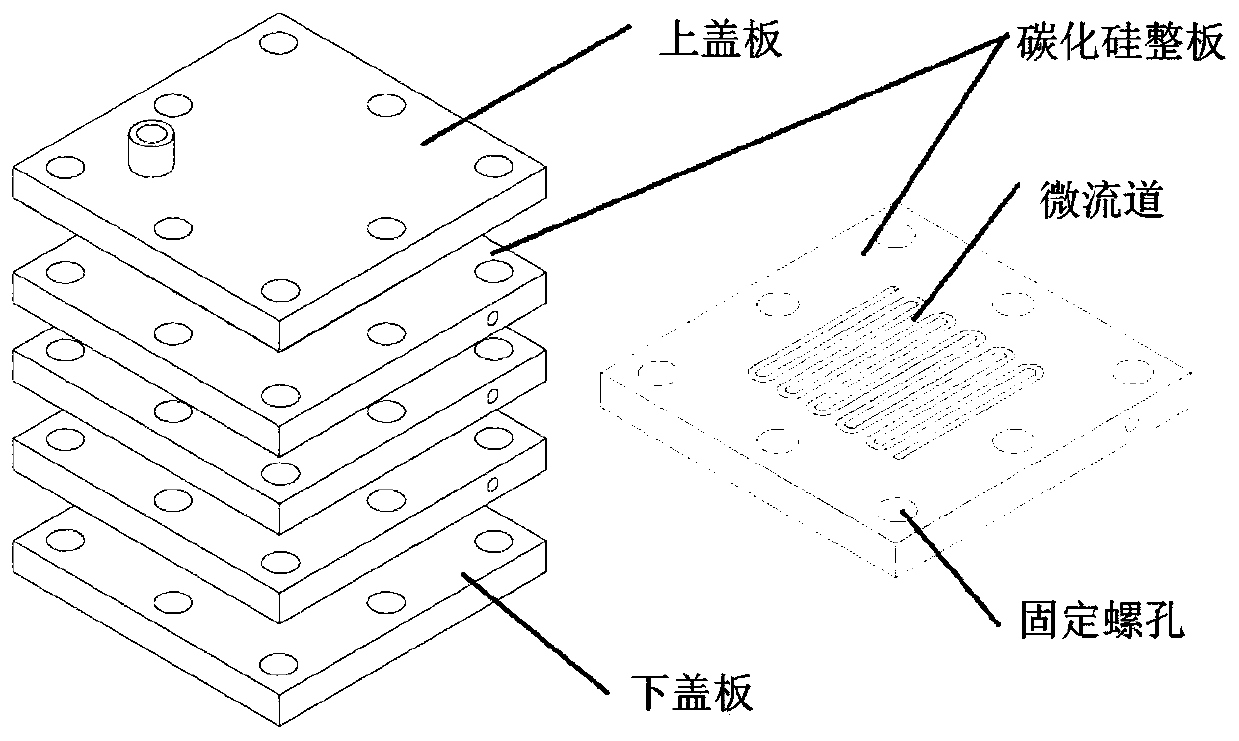

Method used

Image

Examples

Embodiment 1

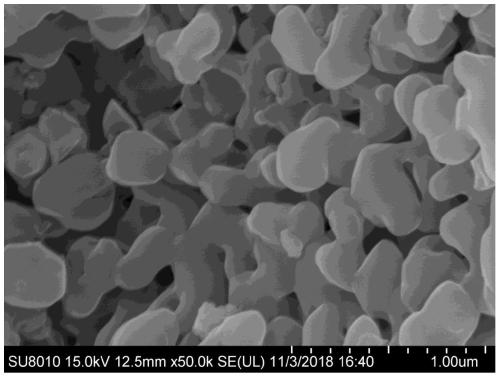

[0037] Step 1: Add 400g of silicon carbide powder to 100g of water, add 6g of alkyl polyoxyethylene ether (AEO), 4g of tetramethylammonium hydroxide, 3g of silicone defoamer, 2g of simethicone release agent, drop Add 20 drops of pH adjuster to adjust the pH value to 9. The silicon carbide powder is negatively charged in water. When the slurry is weakly alkaline, the surface of the particles will absorb positive charges to generate strong electrostatic repulsion. After mixing, use planetary Disperse with a ball mill, use 2mm zirconia microspheres as the dispersion medium, disperse for 20 minutes, then add 5g of modified urea thixotropic agent, continue to disperse for 30 minutes, and prepare a silicon carbide concentrate with a solid phase volume fraction of 55% and a viscosity of 200mPa·s. suspension;

[0038] Step 2: Dissolve 10g of polyvinyl alcohol in a mixed solvent of 80g of water and 10g of dimethylsulfoxide (DMSO) in a water bath at 90°C to obtain 100g of polyvinyl alco...

Embodiment 2

[0046] The same method as in Example 1 was used to prepare the rubber-containing green body, the green body after debinding and the sintered body, and the density test was carried out to the rubber-containing green body, the debinding green body and the sintered body, and 8 samples were taken for each type, wherein There will be holes on the surface of the rubber body and the green body itself after degluing. In order to prevent water from seeping into the test piece, the holes are sealed or filled with paraffin wax. This method is called sealing wax method. The specific steps are as follows: Heat the paraffin wax between 80°C and 90°C, put it into the test piece to make the wax seal the surface or internal holes of the rubber body and the green body after debinding. After the wax sealing is completed, place it at room temperature for about 20 to 30 minutes before weighing. Table 1 shows the measurement results of the relative density of the green body with rubber, the green bo...

Embodiment 3

[0050] After the slurry is grouted and dried, it is easy to be broken by the capillary force between the powder particles, so the resin binder is used to improve the cracking, but too much resin binder will make it impossible to obtain high-density silicon carbide ceramics during sintering workpiece, so an experiment was designed to find out the optimal resin binder content.

[0051] Carry out different polyvinyl alcohol and phenolic resin dosage comparative experiment, operation is basically the same as embodiment 1, difference is that in step 2, polyvinyl alcohol consumption is respectively 50g and 100g, and the consumption of water-soluble phenolic resin is respectively 40g, 60g, 80g, 100g and 120g were mixed to prepare the mixed glue and added to the silicon carbide suspension obtained in step 1. The quality of the blanks obtained in different amounts of phenolic resin and polyvinyl alcohol was shown in Table 2.

[0052] Table 2 The quality of green bodies with different a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com