Stage injection/carving composite fast shaping technology

A forming process and rapid technology, applied in the direction of manufacturing tools, metal processing equipment, control/adjustment systems, etc., can solve the problems affecting the surface quality of the workpiece, material shrinkage and deformation, poor surface quality, etc., to achieve improved strength, high forming accuracy, Density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

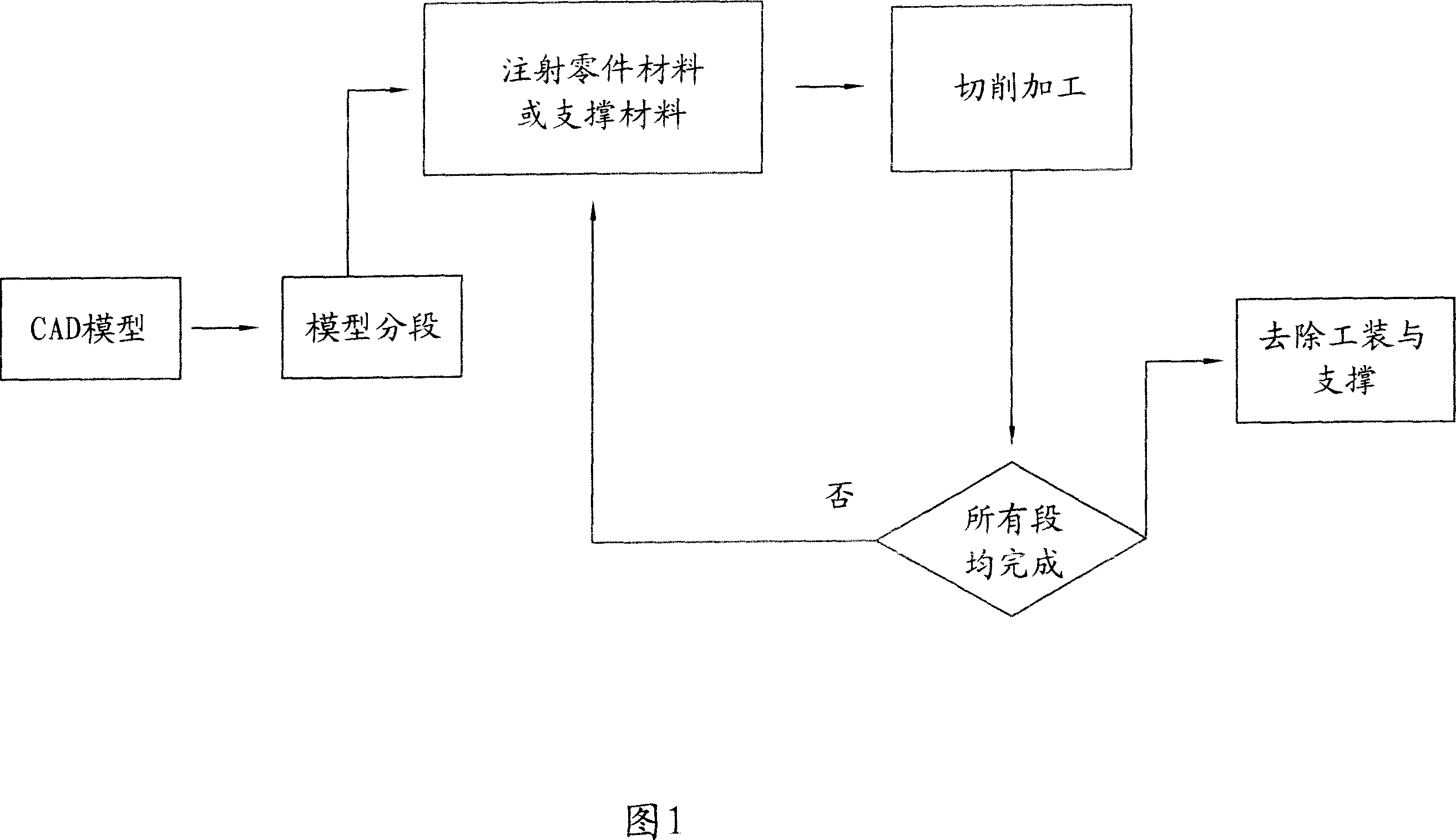

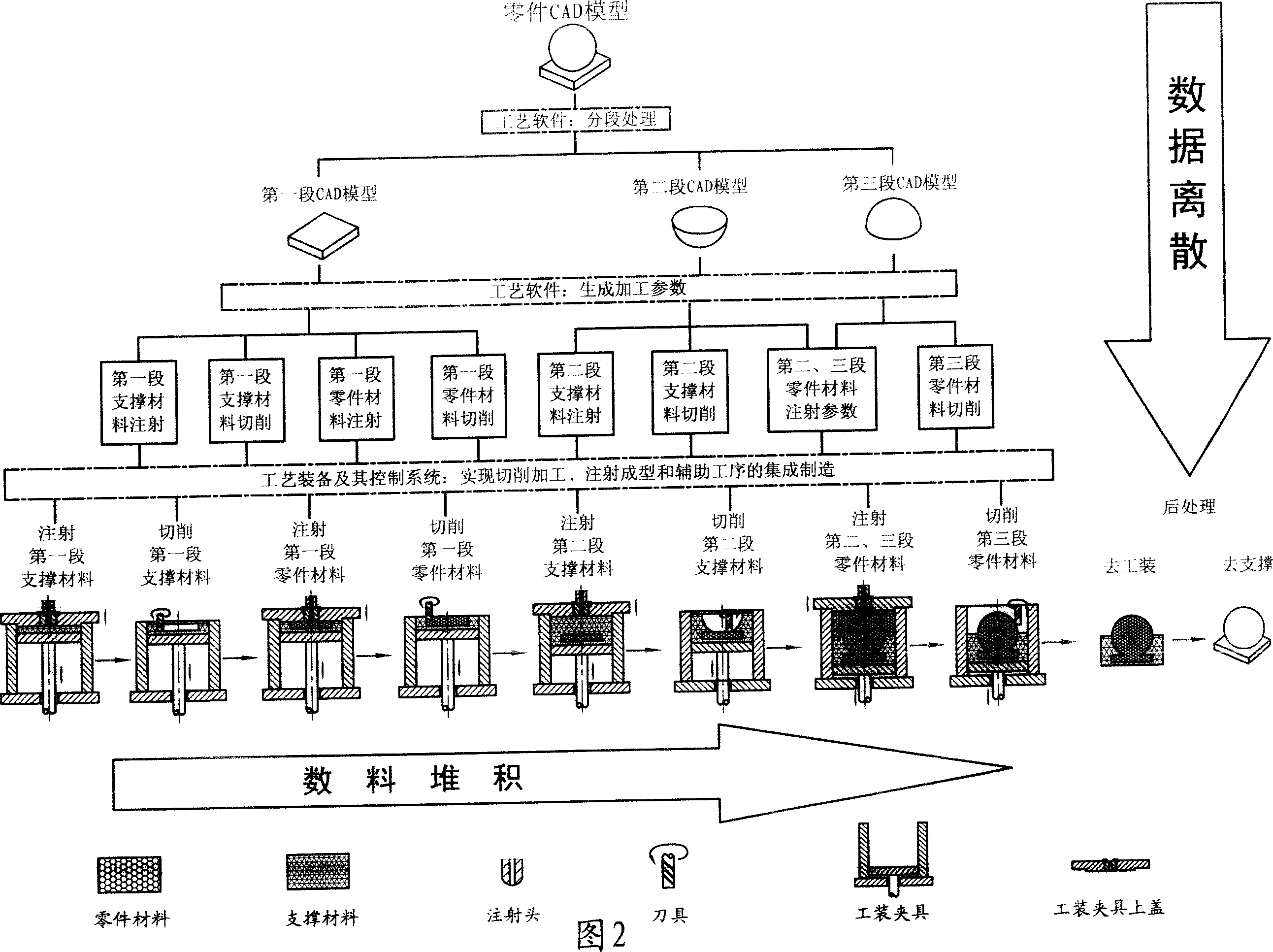

Method used

Image

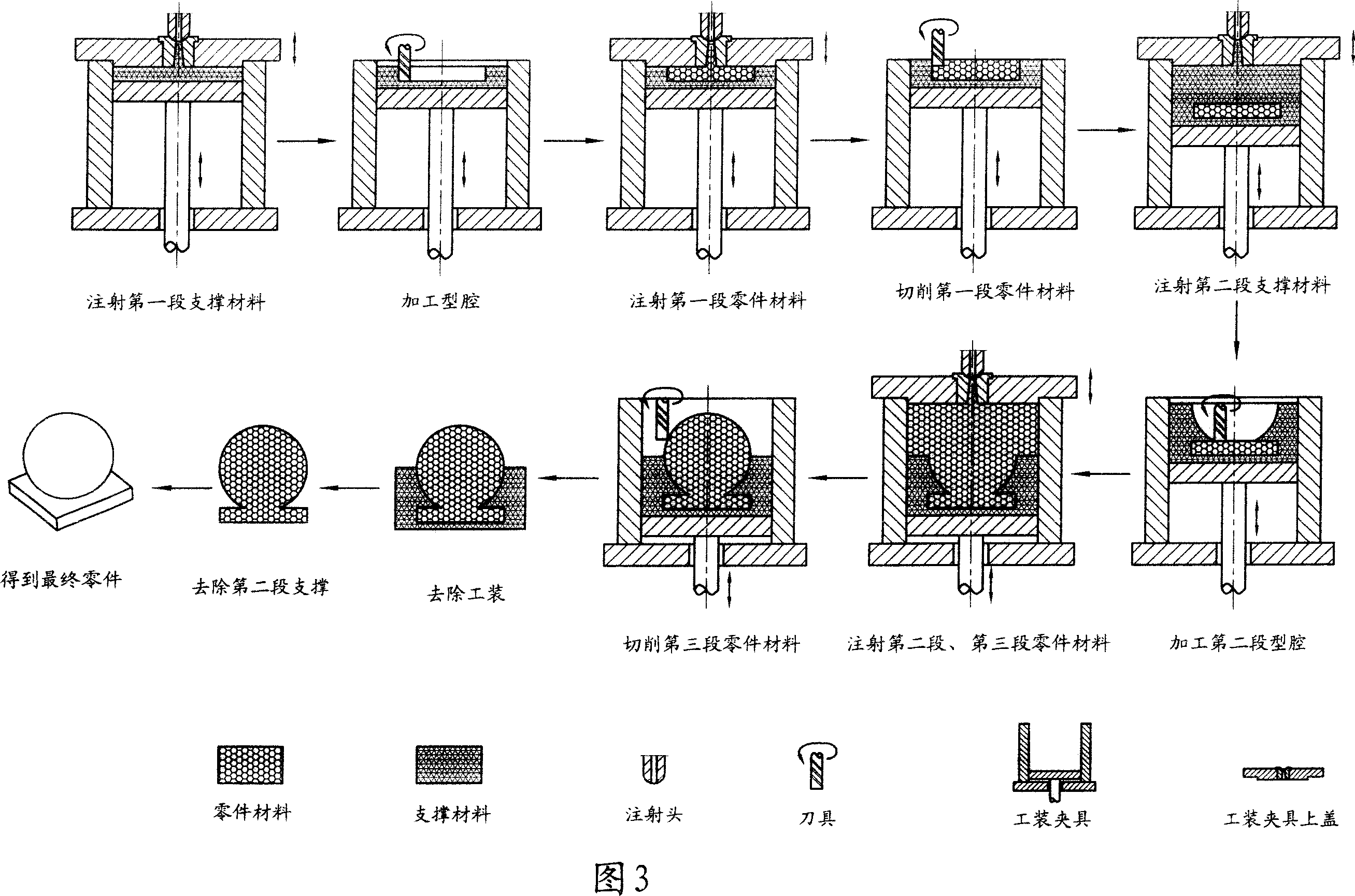

Examples

Embodiment Construction

[0023] Cutting processing and injection molding are adopted respectively in the technology of the present invention, so must select the molding material that meets the requirement. Segmented forming requires that the model data of each segment directly drive the equipment for processing, so it is necessary to research and develop corresponding data processing software and integrated manufacturing equipment.

[0024] Forming materials include part materials and support materials, and have the following characteristics:

[0025] 1) Chemical properties: the two do not undergo chemical reactions, and do not inhibit each other for curing or polymerization;

[0026] 2) Physical properties: the two do not produce miscibility or blending;

[0027] 3) Processing and molding characteristics: the two materials have both good injection performance and good cutting performance;

[0028] 4) Temperature matching characteristics: the injection temperature of the two materials (or the meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com