Plastic gear rack transmission device for mechanical arm

A technology of rack drive and manipulator, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve the problems of complex manipulator structure, short service life, and large transmission noise, and achieve light weight, simple structure and production process, and transmission low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

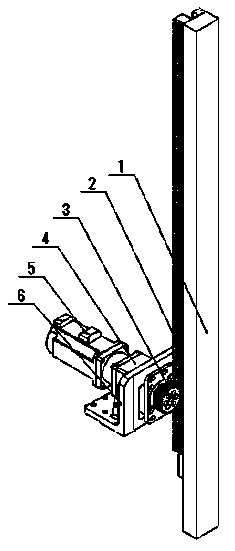

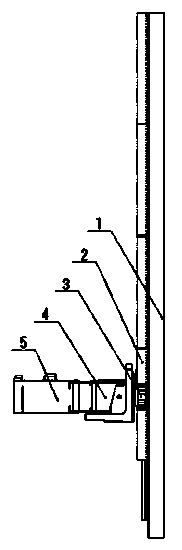

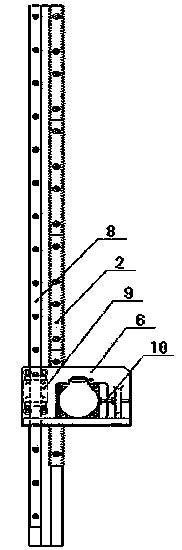

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the motor 5 is fixed on the reducer 4, the drive gear 3 is directly installed on the shaft of the reducer 4, the reducer 4 is fixed on the reducer fixing plate 7 with screws, and the reducer fixing plate 7 is fixed on the unit bracket with screws 6, a guide rail 8 is installed on the left side of the sliding arm 1, and two sliders 9 are installed on the unit bracket 6. 8. An injection-molded plastic rack 2 is installed in parallel splicing. The plastic rack 2 is fixed and locked with the sliding arm 1 by screws on the installation basis. The plastic rack 2 has a symmetrical structure on both sides. The driving gear 3 and the plastic rack 2 mesh.

[0016] Adjust the meshing gap between the driving gear 3 and the plastic rack 2 through the outer hexagonal adjustment screw 10, and then use a wrench to lock the reducer 4 and the reducer fixing plate 7 to ensure that the drive gear 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com