Display panel, manufacturing method thereof and display device

A technology for display panels and display areas, applied in lamination devices, chemical instruments and methods, transportation and packaging, etc., can solve problems such as easy breakage, light leakage, Mura, etc., to improve strength and reliability, increase thickness, avoid The effect of black screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

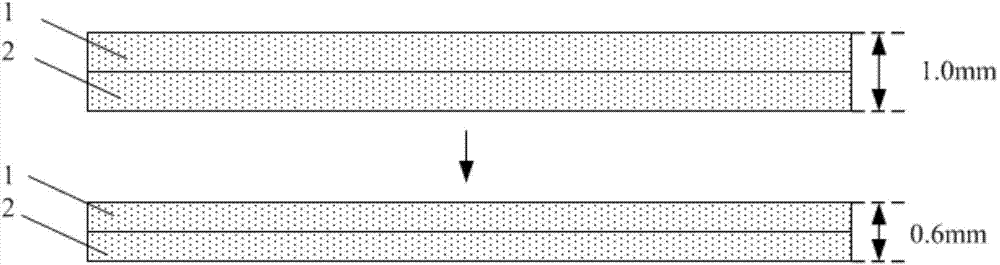

[0039] This embodiment provides a method for preparing a display panel and a display panel formed by using the method. By using the method, a partially thinned display panel can be easily formed, so that display panels with different thicknesses can be formed in partitions, and can simultaneously adapt to The driver IC is attached and the strength of the display panel is ensured to better realize the thinning of the display panel; and the thickness of the display area of the display panel is ensured to avoid light leakage and COG Mura defects.

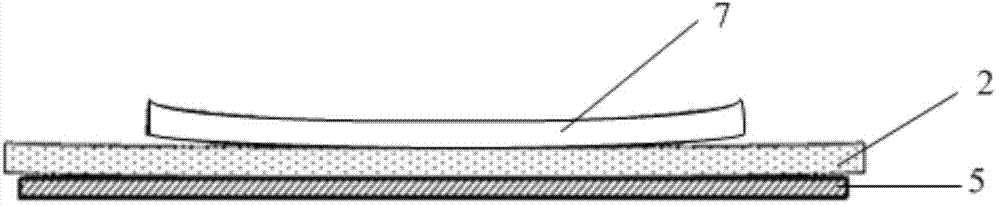

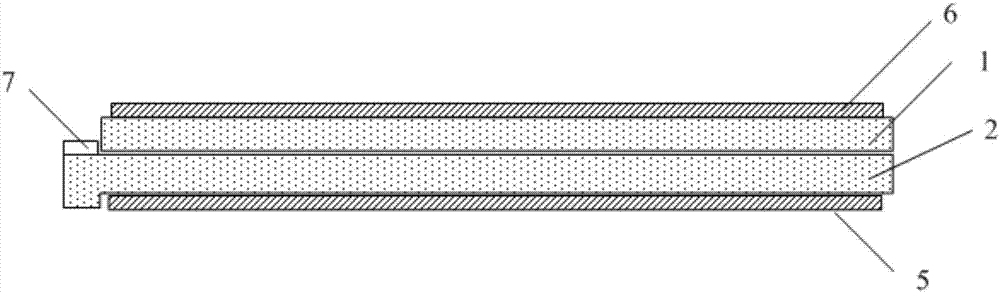

[0040] This embodiment provides a display panel, the two sides of the display panel are respectively the first surface and the second surface, such as figure 2 As shown, the display panel includes a first substrate and a second substrate opposite to each other (the outer side of the first substrate relative to the second substrate is the first surface, and the outer side of the second substrate relative to the first substrate is the ...

Embodiment 2

[0087] This embodiment provides a display device, including the display panel in Embodiment 1.

[0088] On the substrate of the display panel in Embodiment 1, taking the liquid crystal display panel as an example, the backlight source 10 is assembled according to the normal assembly process, that is, the following Figure 5 The display device shown.

[0089] The display device can be any product or component with a display function such as a liquid crystal panel, an electronic paper, an OLED panel, a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0090] The display device adopts the above-mentioned display panel, so it has better display effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com