Liquid crystal box thinning method and liquid crystal box thinning equipment

A liquid crystal cell and equipment technology, applied in optics, non-electric variable control, instruments, etc., can solve the problems of large differences in the overall thickness of the liquid crystal cell, incomplete cutting, fragmentation, etc., achieve good optical characteristics, and eliminate the effect of the overall thickness difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

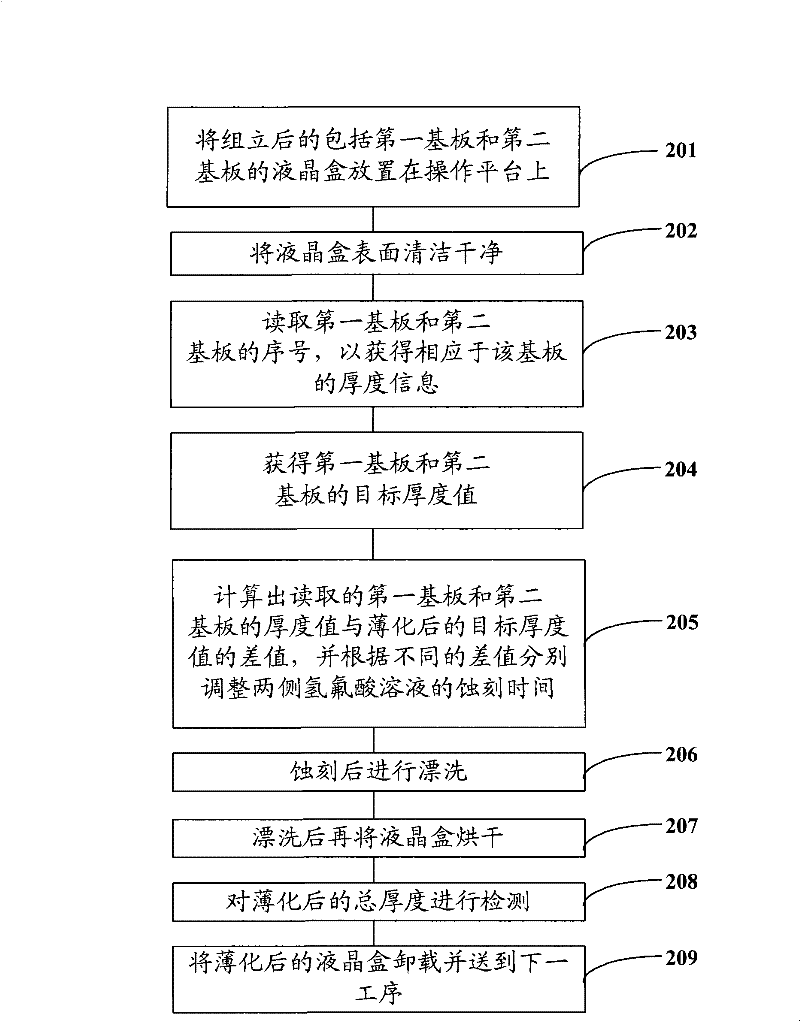

[0022] figure 2 It is a schematic process flow diagram of a liquid crystal cell thinning method according to an embodiment of the present invention.

[0023] Step 201, placing the assembled liquid crystal cell including the first substrate and the second substrate on the operation platform.

[0024] Wherein, the first substrate may be a color filter substrate, the second substrate may be a thin film transistor substrate, and the first substrate and the second substrate may be purchased from different suppliers, and may be of different batches. manufactured products. The specifications of the first substrate and the second substrate can be all specifications that can be supplied by the substrate supplier, specifically, they can be, for example, 0.5 mm, 0.6 mm, 0.7 mm, 0.8 mm, and 0.9 mm. The first substrate and the second substrate are in the same specification, and their thickness parameters may be within a thickness error range of 10%. Taking a substrate with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com