High-efficiency germanium-based flexible multi-junction solar cell and its preparation method

A solar cell and high-efficiency technology, applied in the field of solar cells, can solve the problems of poor thickness uniformity and inability to directly obtain flexible multi-junction solar cells, etc., to balance stress, improve open circuit voltage and spectral response, and improve conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A high-efficiency germanium-based flexible multi-junction solar cell and its preparation method according to the present invention will be described in detail below in combination with the manufacturing method.

[0020] A high-efficiency germanium-based flexible multi-junction solar cell, comprising the following steps:

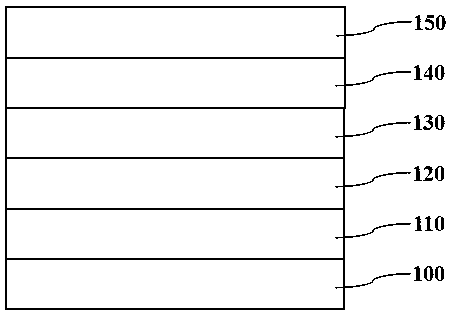

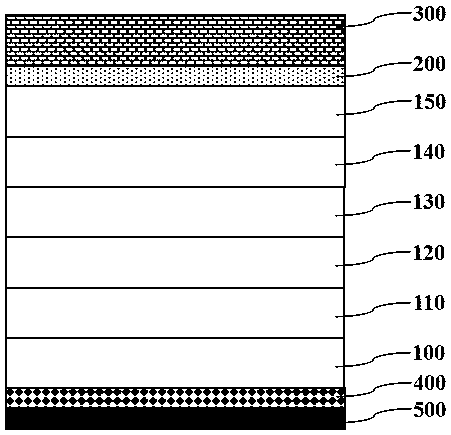

[0021] 1. Clean a p-type Ge substrate 100 with a thickness of 140 μm, put it into the MOCVD reaction chamber, set the chamber pressure at 120 mbar, and run the epitaxial growth program to obtain the first Ge sub-cell 110 and the GaAs second sub-cell in sequence. A tunnel junction 120, a second InGaAs subcell 130, a second GaInP / AlGaAs tunnel junction 140, and a third GaInP subcell 150, thereby obtaining a GaInP / InGaAs / Ge triple-junction solar cell on a Ge substrate, such as figure 1 shown;

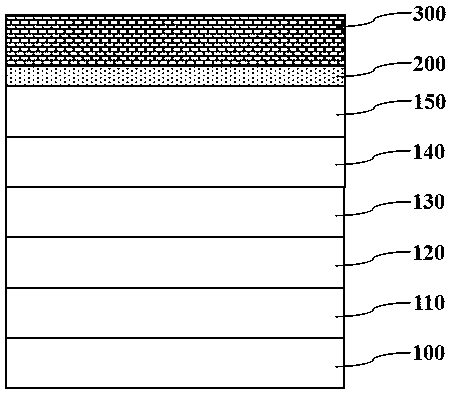

[0022] 2. Use BCB glue 200, pressure 1000kgf, and temperature 250°C for 30 minutes to bond the upper surface of the GaInP / InGaAs / Ge triple-junction solar cell on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com