Production method of chemical fiber window screening and setting machine needed by same

A production method and technology of a setting machine, which are applied to window decorations, textile material processing, curtains and other directions, can solve the problems of weak two-way mesh of polypropylene plain weave, short service life, easy to produce pollution, etc. The production process cost is low, the operation is simple, and the process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

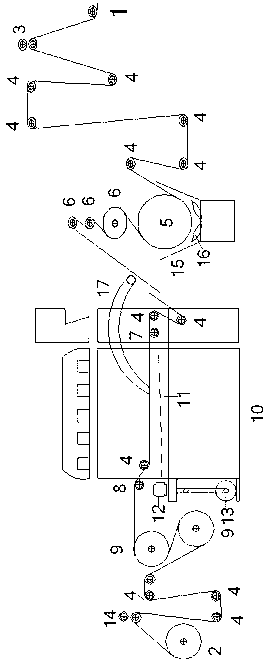

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises an unwinding device 1 and a rewinding device 2, the unwinding device 1 and the rewinding device 2 pass through the traction wheel 3, the tension roller 4, the pulp hanging roller 5, the squeeze roller 6, the upper cloth wheel 7, Needle removal roller 8, cooling roller 9, and winding roller 14 are connected, and tension rollers are arranged between squeezing roller 6 and upper cloth wheel 7, upper cloth wheel 7 and needle removal roller 8, cooling roller 9 and winding roller 14 4. The tension roller 4 between the upper cloth wheel 7 and the needle-removing roller 8 is located in the oven 10. The track chain 11 that drives the mesh cloth is also set in the oven 10. The slurry hanging roller 5 is placed in the trough 15, and the traction wheel 3 It belongs to the on-line equipment, the material trough 15 and the hanging roller 5 belong to the gluing and coloring equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com