Novel composite cooker and manufacturing method thereof

A manufacturing method and a new type of technology, applied in the direction of household appliances, kitchen utensils, special materials for cooking utensils, etc., can solve the problems of easy generation of oil fume and scorched food, uneven heating of the pot body, endangering health, etc., and increase practicability. and energy saving, reducing the phenomenon of sticking to the pan, reducing the effect of the harm of the link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

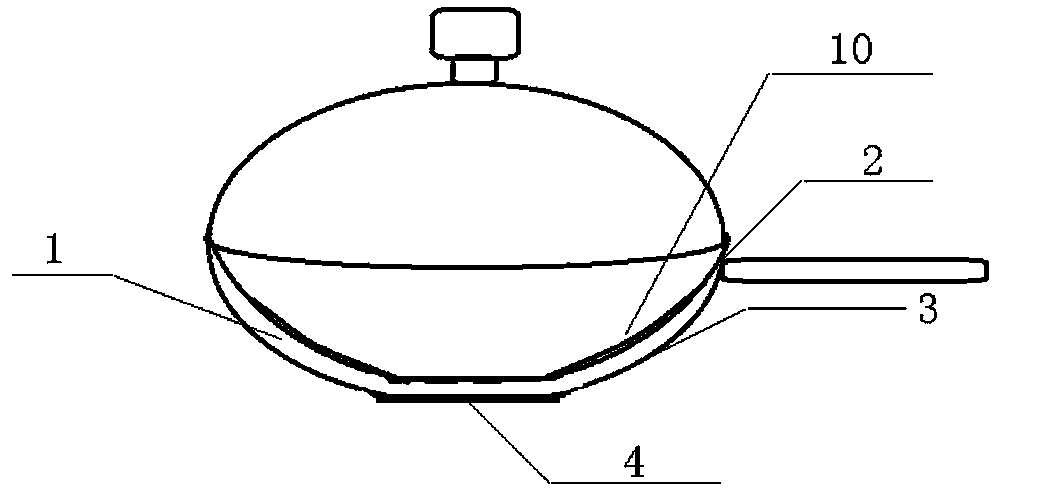

[0035] Embodiment 1, with reference to attached figure 1 , Pot body 1.

[0036] Cooker of the present invention comprises pot body 1, and the thickness of pot body 1 is 1.5mm~2.0mm. Pot wall The edge of the pot wall is gradually reduced at a distance of 2mm.

[0037] The pot body 1 includes an inner layer pot body 2 and an outer layer pot body 3. The material of the inner layer pot body 2 is selected from any one of iron, iron-based alloy, stainless steel, titanium, and titanium alloy materials. The inner layer pot body 2 The thickness is 0.25 mm to 0.5 mm. The surface of the inner pot body 2 has anti-stick or anti-stick bumps, patterns or ribs 10. The material of the outer pot body 3 is selected from aluminum alloy, pure aluminum, AZ31B magnesium alloy or magnesium For any alloy, the thickness of the outer pot body 3 is 1.0 mm to 1.5 mm, and the surface of the outer pot body 3 is provided with concave-convex grooves or stepped threads. The outer surface of the outer pot bo...

Embodiment 2

[0040] Embodiment 2, with reference to attached figure 1 , Pot body 2.

[0041] Cooker of the present invention comprises pot body 1, and the thickness of pot body 1 is 2.0mm~3.5mm. Pot wall The edge of the pot wall is gradually reduced at a distance of 3mm.

[0042] The pot body 1 includes an inner layer pot body 2 and an outer layer pot body 3. The material of the inner layer pot body 2 is selected from any one of iron, iron-based alloy, stainless steel, titanium, and titanium alloy materials. The inner layer pot body 2 The thickness is 0.5 mm to 0.8 mm. The surface of the inner pot body 2 has anti-stick or anti-stick bumps, patterns or ribs 10. The material of the outer pot body 3 is selected from aluminum alloy, pure aluminum, AZ31B magnesium alloy or magnesium For any alloy, the thickness of the outer pot body 3 is 1.5 mm to 2.0 mm, and the surface of the outer pot body 3 is provided with concave-convex grooves or stepped threads. The outer surface of the outer pot bod...

Embodiment 3

[0045] Embodiment 3, with reference to attached figure 1 , pot body 3.

[0046] Cooker of the present invention comprises pot body 1, and the thickness of pot body 1 is 3.5mm~4.0mm. Pot wall The edge of the pot wall is gradually reduced at a distance of 2mm.

[0047] The pot body 1 includes an inner layer pot body 2 and an outer layer pot body 3. The material of the inner layer pot body 2 is selected from any one of iron, iron-based alloy, stainless steel, titanium, and titanium alloy materials. The inner layer pot body 2 The thickness is 0.8 mm ~ 1.0 mm. The surface of the inner layer pot body 2 has anti-stick or anti-stick bumps, patterns or ribs 10. The material of the outer layer pot body 3 is selected from aluminum alloy, pure aluminum, AZ31B magnesium alloy or magnesium For any alloy, the thickness of the outer pot body 3 is 2.0 mm to 3.0 mm, and the surface of the outer pot body 3 is provided with concave-convex grooves or stepped threads. The outer surface of the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com