Low-pressure diffusion technique in solar cell silicon wafer production process

A solar cell and diffusion process technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems affecting service life and working performance, easy diffusion of liquid phosphorus sources, corrosion of equipment and instruments, etc. The effect of fewer defects and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

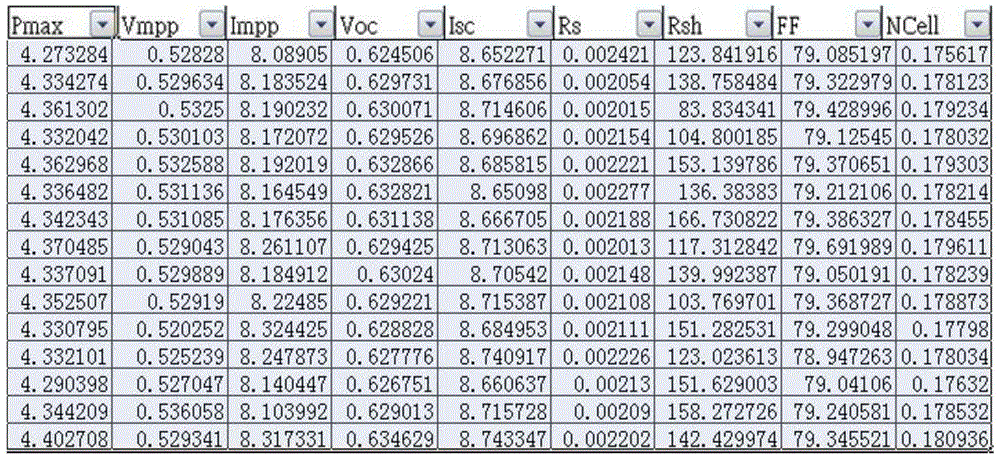

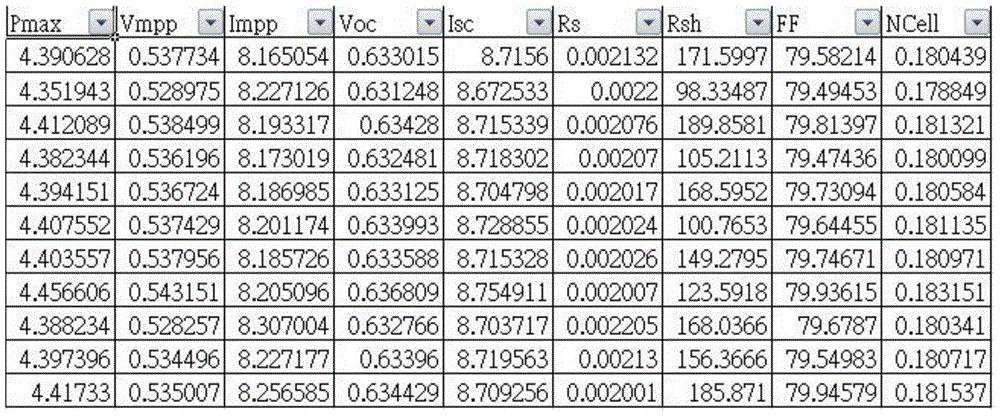

Examples

Embodiment Construction

[0021] The following are specific examples of the present invention to further describe the technical solutions of the present invention, but the present invention is not limited to these examples.

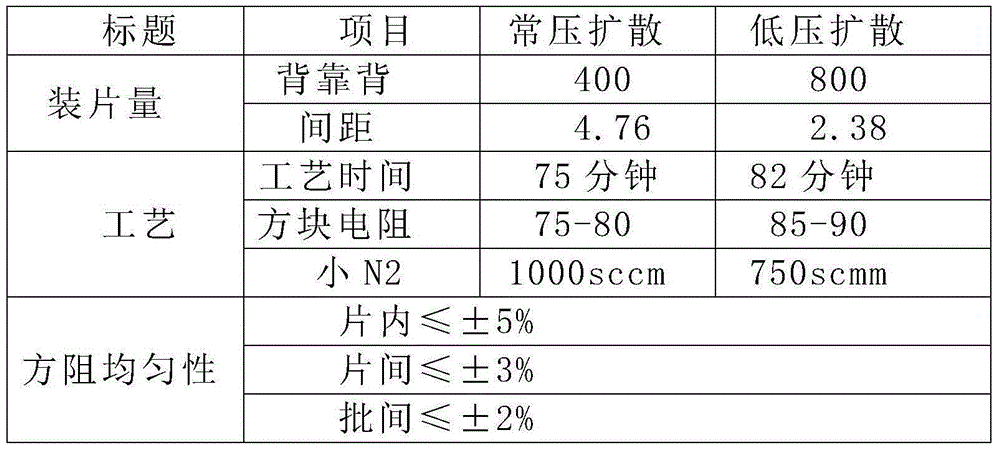

[0022] A low-voltage diffusion process in the production process of solar cell silicon wafers, the low-voltage diffusion process includes the following steps:

[0023] a. Vacuuming: Place the silicon wafer in the reaction chamber of the diffusion furnace, check the sealing of the diffusion furnace door, close the furnace door of the diffusion furnace to ensure the sealing, and use a vacuum pump to pump the reaction chamber of the diffusion furnace to 50mbar~ In a vacuum state of 150mbar, the exhaust air volume at the end of the tube of the reaction chamber is reduced to 1 / 3 of the maximum air volume; the diffusion furnace is a tube furnace, and the reaction chamber is a tube cavity;

[0024] B, filling body: a small amount of nitrogen and phosphorus oxychloride are rushed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com