Preparation method of lithium ion battery electrode active material

A technology for electrode active materials and lithium-ion batteries, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of inhomogeneity, high cost of raw materials, low activity, etc., and achieve uniform particle size distribution and high tap density , The effect of less lattice defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

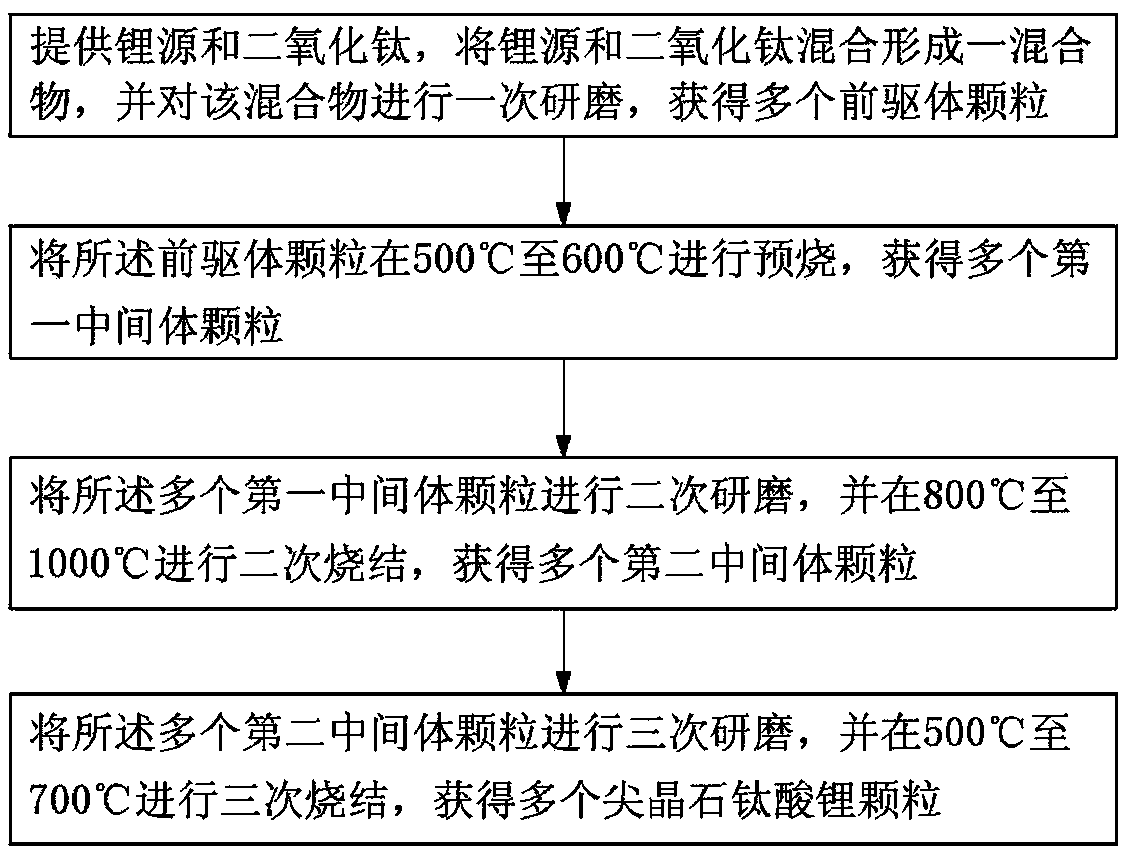

[0016] The first embodiment of the present invention provides a preparation method of lithium-ion battery electrode active material, which comprises the following steps:

[0017] S1, providing a lithium source and titanium dioxide, mixing the lithium source and titanium dioxide to form a mixture, and grinding the mixture for the first time to obtain a plurality of precursor particles;

[0018] S2, pre-calcining the precursor particles at 500°C to 600°C to obtain a plurality of first intermediate particles;

[0019] S3, grinding the plurality of first intermediate particles for a second time, and performing second sintering at 800°C to 1000°C to obtain a plurality of second intermediate particles; and

[0020] S4, grinding the plurality of second intermediate particles for a third time, and performing a third sintering at 500° C. to 700° C. to obtain a plurality of spinel lithium titanate particles.

[0021] In the above step S1, the lithium source may be lithium salt, lithium...

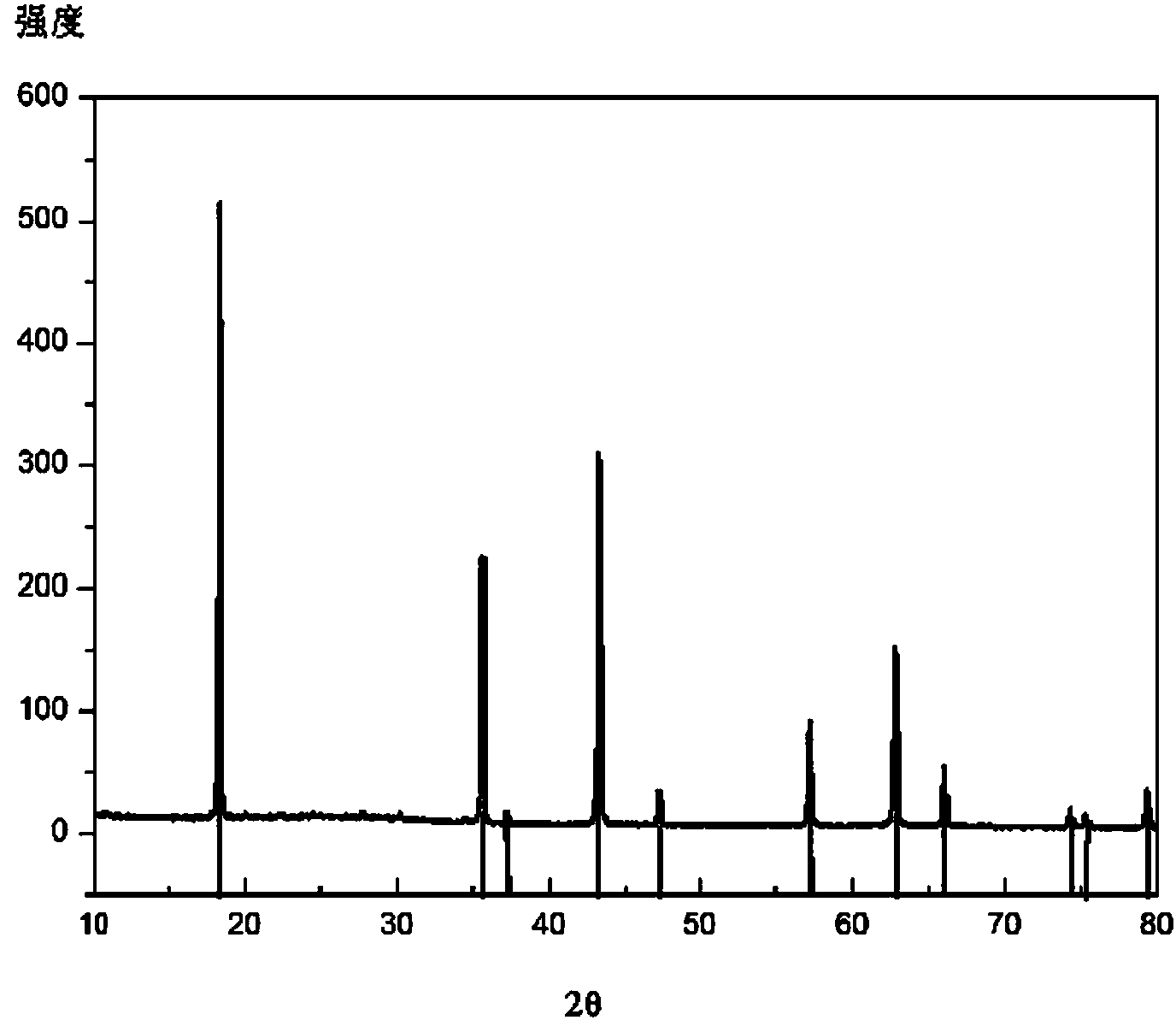

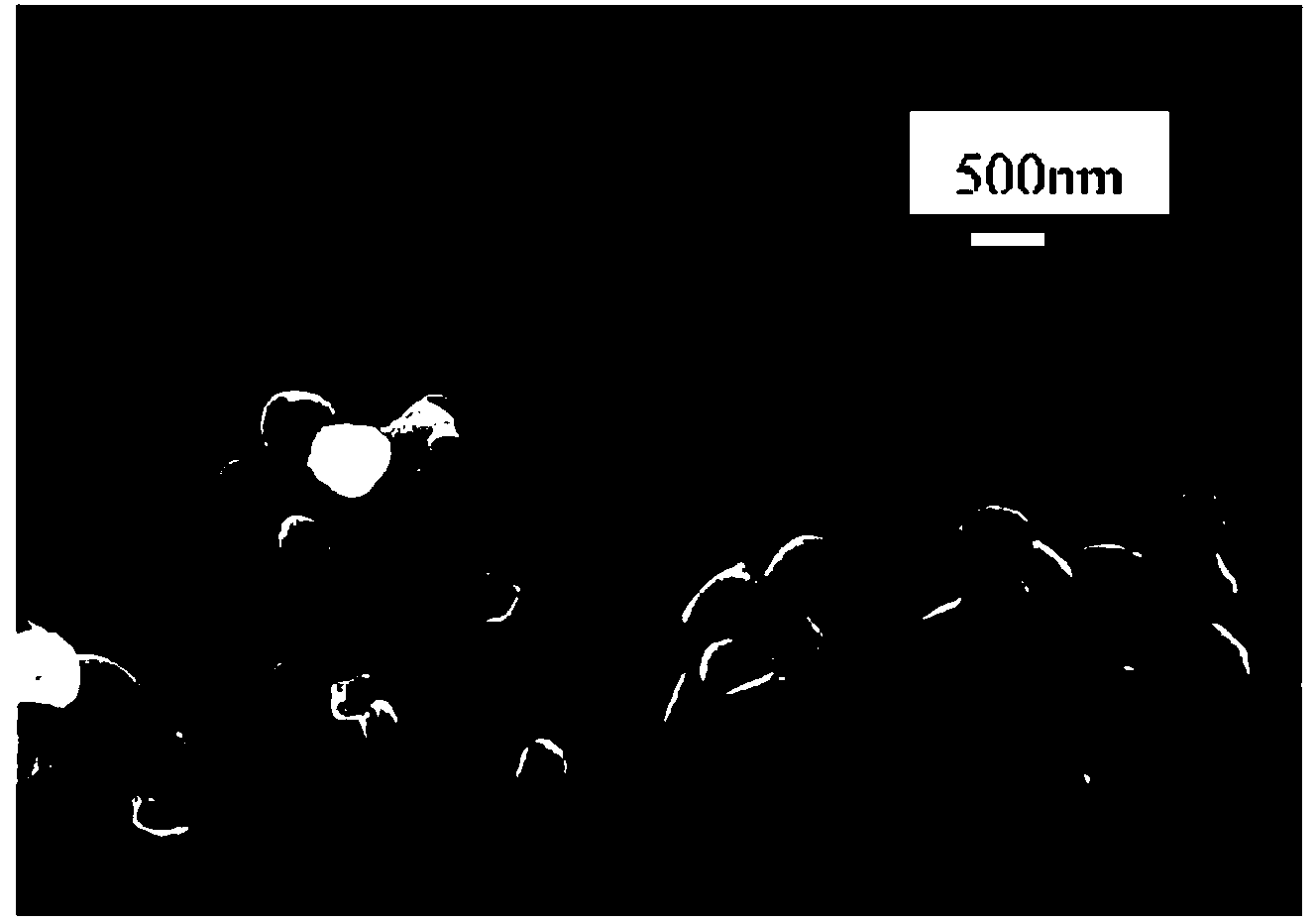

Embodiment 1

[0062] (a) Take 2.7281g of lithium carbonate, 7.2989g of anatase-type titanium dioxide, and 20ml of ethanol solution, put them together in an agate jar, add an appropriate amount of agate balls, and ball mill at a speed of 400rmp for 4 hours to obtain a mixed slurry, and then force the mixed slurry Ultrasound for 1 hour to reduce particle agglomeration, vacuum dry at 60°C for 2 hours, and then sieve with a 400-mesh sieve to obtain multiple precursor particles;

[0063] (b) Put the above-mentioned precursor particles in a muffle furnace, raise the temperature to 500°C at a rate of 5°C / min in an air environment under normal pressure and keep it warm for 6 hours, and cool naturally after the heat preservation is completed to obtain multiple first intermediates particles;

[0064] (c) Put the above-mentioned first intermediate particles in an agate jar, add an appropriate amount of agate balls, mill at a speed of 500 rpm for 4 h, and perform the second grinding. After the second g...

Embodiment 2

[0073] (a) Add 50ml of ethanol, 1g of lithium titanate particles (LTO) prepared in Example 1, 0.3725g of styrene monomer and 0.0077g of benzoyl peroxide (BPO) initiator into a three-necked flask, and stir with magnetic force Stir to make it evenly mixed;

[0074] (b) Heating to 80°C under stirring conditions, reacting at 80°C for 2 hours, and then placing it in a constant temperature device at 150°C for 10 hours to obtain a mixed solution containing lithium titanate particles coated with polystyrene on the surface;

[0075] (c) Suction filter the above mixed solution to obtain polystyrene-coated lithium titanate particles, and wash the lithium titanate particles with methanol;

[0076] (d) The polystyrene-coated lithium titanate particles were vacuum-dried at 80°C for 12h, placed in a tube furnace under N2 protection, and sintered at 600°C for 1h to obtain carbon-coated lithium titanate particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com