Method for preparing beta-silicon carbide film

A technology of silicon carbide and thin film, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of difficult application of silicon carbide materials, reduce lattice defects, improve heat dissipation performance and service life, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

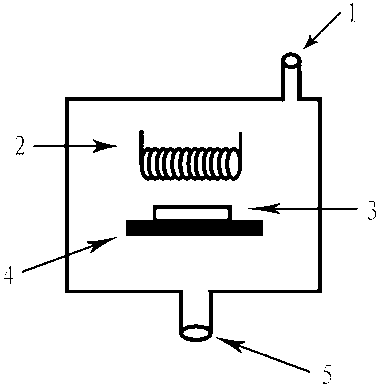

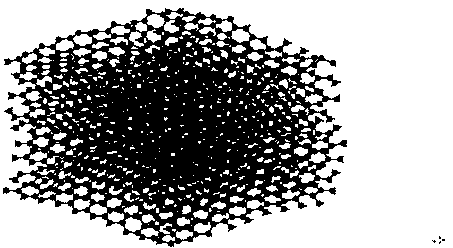

[0034] The preparation method of a kind of β-silicon carbide film of the present invention comprises the following steps:

[0035] Step 1: Divide the 0.5×0.5 mm 2 The graphite substrate with high electrical conductivity and thermal conductivity was cleaned with acetone, absolute ethanol and deionized water for 10 minutes in sequence, and then the substrate was blown dry with high-purity nitrogen.

[0036] Step 2: Optimizing experimental parameters such as silane concentration, reaction system gas pressure, and substrate temperature; the silicon source is silane with a concentration of 10%, the gas flow rate is 0.5 sccm, the gas pressure of the reaction system is 40Pa, and the substrate temperature is 300°C.

[0037] Step 3: Grow a layer of silicon carbide (SiC) film (100 nm) on the pre-cleaned graphite substrate using HFCVD technology, wherein the temperature of the hot tungsten wire is 2000 °C.

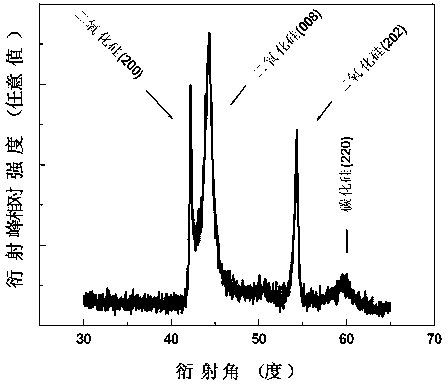

[0038] Step 4: The above-mentioned SiC film is annealed in argon at 500° C. for...

Embodiment 2

[0041] The preparation method of a kind of β-silicon carbide film of the present invention comprises the following steps:

[0042] Step 1: Place 0.5×0.5 cm 2 The graphite substrate with high electrical conductivity and thermal conductivity was cleaned with acetone, absolute ethanol and deionized water for 10 minutes in sequence, and then the substrate was blown dry with high-purity nitrogen.

[0043] Step 2: Optimizing experimental parameters such as silane concentration, reaction system gas pressure, and substrate temperature; the silicon source is silane with a concentration of 10%, the gas flow rate is 0.5 sccm, the gas pressure of the reaction system is 40Pa, and the substrate temperature is 300°C.

[0044] Step 3: Grow a layer of silicon carbide (SiC) film (100 nm) on the pre-cleaned graphite substrate using hot wire chemical vapor deposition (HFCVD), where the temperature of the hot tungsten wire is 2000 °C.

[0045] Step 4: The above-mentioned SiC thin film is annealed i...

Embodiment 3

[0048] The preparation method of a kind of β-silicon carbide film of the present invention comprises the following steps:

[0049] Step 1: Place 0.5×0.5 cm 2 The graphite substrate with high electrical conductivity and thermal conductivity was cleaned with acetone, absolute ethanol and deionized water for 10 minutes in sequence, and then the substrate was blown dry with high-purity nitrogen.

[0050] Step 2: Optimizing experimental parameters such as silane concentration, reaction system gas pressure, and substrate temperature; the silicon source is 10% silane, the gas flow rate is 0.5 sccm, the gas pressure of the reaction system is 40Pa, and the substrate temperature is 300°C.

[0051] Step 3: Grow a layer of silicon carbide (SiC) film (100 nm) on the pre-cleaned graphite substrate using hot wire chemical vapor deposition (HFCVD), where the temperature of the hot tungsten wire is 2000 °C.

[0052] Step 4: The above SiC film is annealed in argon at 700° C. for 30 minutes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com