Band gap tunable copper zinc tin sulfur semiconductor film and preparation method thereof

A copper-zinc-tin-sulfur and semiconductor technology, which is applied in the field of adjustable band gap copper-zinc-tin-sulfur semiconductor films and their preparation, can solve the problem that the crystal quality and structural properties of the films cannot be optimized, and it is difficult to obtain high-quality copper-zinc-tin-sulfur films. It can improve the photoelectric conversion efficiency, reduce the infiltration of harmful gases, and achieve good compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation process for an adjustable bandgap copper-zinc-tin-sulfur semiconductor thin film, the process is as follows:

[0032] 1) Clean the substrate substrate

[0033] Using a glass slide as the substrate, first use ammonia water (the ammonia content is 27wt%), 30wt% hydrogen peroxide solution and water at a volume ratio of 0.5:1:5, and then ultrasonically clean the No. 1 cleaning solution obtained after mixing Clean for 5 minutes, then wash with deionized water for 3 times, then use the volume ratio of 36.5wt% hydrochloric acid, 30wt% hydrogen peroxide solution and water to mix the obtained No. 2 cleaning solution for ultrasonic cleaning for 5 minutes, Then wash 3 times with deionized water, and store the cleaned slides in 75% alcohol solution for later use.

[0034] 2) Preparation of layered metal thin film precursor

[0035] Put 99.99% and above purity powder or flake or wire copper, zinc and tin metals in different tungsten boats, and conduct thermal evapora...

Embodiment 1

[0039] Example 1 (Cu 2.1 Zn 1.05 SnS 4 )

[0040] Take copper powder (10.9mg), zinc powder (5.5mg) and tin powder (9.6mg) and place them in three tungsten boats respectively, and conduct thermal evaporation deposition of the metal layer on a vacuum coating machine. The order of evaporation deposition is Cu-Zn- Sn metal layer, to obtain a layered metal thin film precursor deposited on a glass slide.

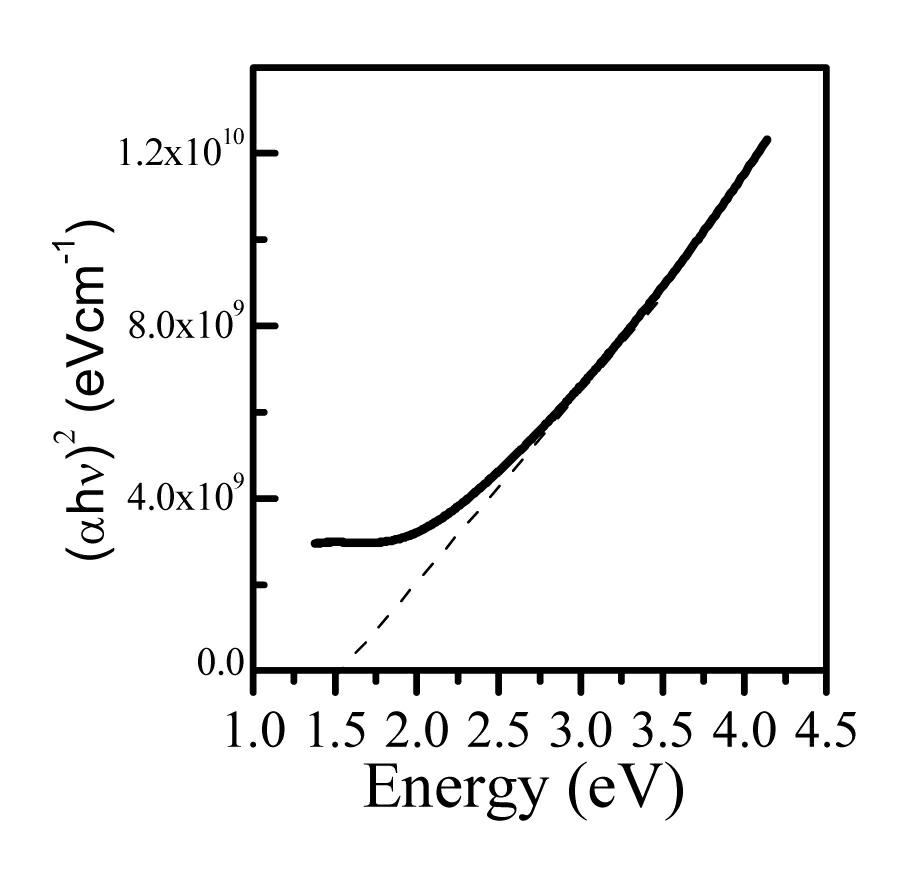

[0041] Put the above glass slide and sufficient amount of sulfur powder in a vacuum furnace to heat, first raise the temperature to 400 °C for 60 min, then keep it warm for 2 h, and finally obtain a copper-zinc-tin with a thickness of 1 μm and an optical band gap of 1.51 eV. Sulfur semiconductor thin films.

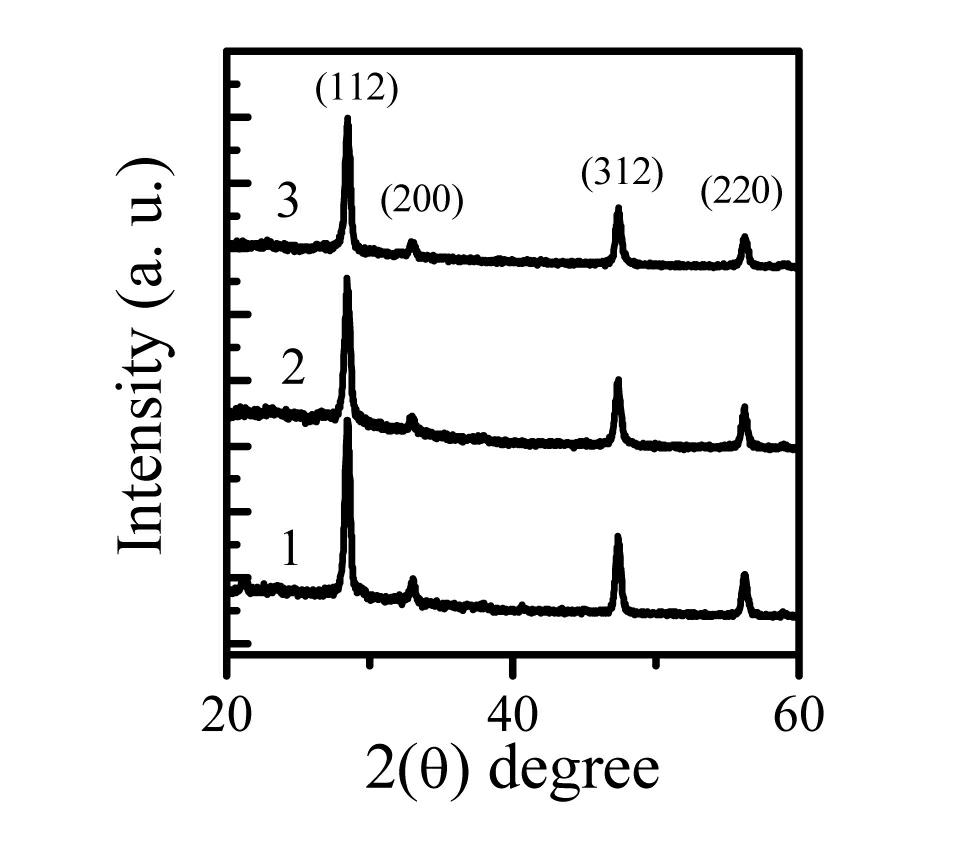

[0042] figure 1It is the XRD figure of embodiment 1 and comparative example semiconductor thin film, there are three curves in the figure, is respectively curve 3, curve 2, curve 1 from top to bottom, and curve 1 is the XRD figure of embodiment 1 semiconductor thin fil...

Embodiment 2

[0043] Example 2 (Cu 2.4 Zn 0.95 SnS 4 )

[0044] Take copper wire (12.1mg), zinc sheet (5.5mg) and tin wire (9.6mg) and place them in three tungsten boats, and conduct thermal evaporation deposition of metal layers on a vacuum coating machine. The order of evaporation deposition is Cu-Sn- The Zn metal layer was deposited on a glass slide to obtain a layered metal thin film precursor.

[0045] Put the above glass slide and sufficient amount of sulfur powder in a vacuum furnace to heat, first raise the temperature to 300 ℃ for 60 minutes, and then keep it warm for 2 hours, finally get the adjustable bandgap copper-zinc with a thickness of 1.1μm and an optical bandgap of 1.2eV Tin-sulfur semiconductor thin films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com