Carbon-coated solid electrolyte material as well as preparation method and application thereof

A solid electrolyte and carbon-coated technology, which is applied in the field of carbon-coated solid electrolyte materials and their preparation, can solve problems such as poor conductivity, poor rate performance, and large battery polarization, and achieve less lattice defects and a degree of graphitization Effect of high performance improvement on lithium ion conductivity and electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The NASICON solid electrolyte material Li with a particle size of 1 μm 1.2 al 0.2 Ti 1.8 (PO 4 ) 3 (LATP) and sucrose were added to the mixer at a mass ratio of 10:1, and water was added to stir for 1 hour. After mixing thoroughly, it was dried at 120°C, put into the reaction equipment, and the temperature was raised to 650°C at a rate of 5°C / min; Calcined at a constant temperature for 2 hours in an argon atmosphere with a flow rate of 0.1 L / min, cooled to room temperature, and pulverized the material to obtain a carbon-coated solid electrolyte material.

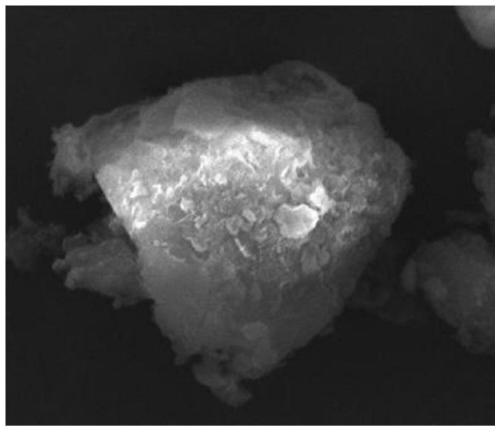

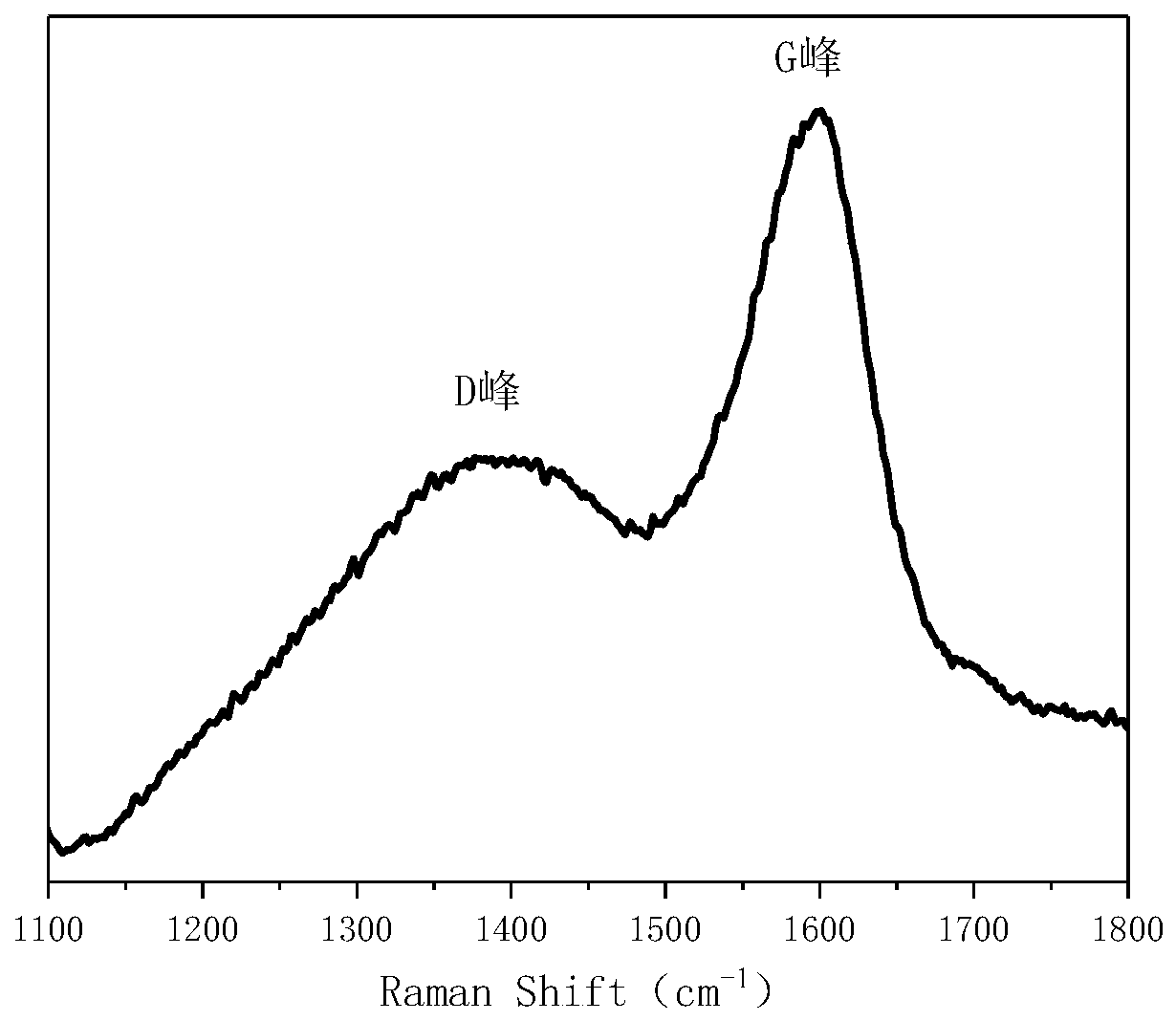

[0058] figure 1 It is a scanning electron microscope (SEM) figure of the obtained carbon-coated solid electrolyte material, and its Raman spectrum figure is as follows figure 2 shown.

[0059] According to the SEM image, it can be seen that the carbon-coated solid electrolyte material is a polygonal irregular shape; according to figure 2 The Raman spectrum of the material shows that the material has obvious D...

Embodiment 2

[0062] The garnet-type solid electrolyte material Li with a particle size of 500 nm 7 Ca 3 Ta 2 o 12 (LCTO) and citric acid were added to the container at a mass ratio of 50:1, water was added and ultrasonically oscillated for 1 hour, mixed thoroughly, dried at 110°C, put into the reaction equipment, and heated to 480°C at a rate of 2°C / min; Calcined at a constant temperature for 4 hours in an argon atmosphere with a flow rate of 0.4 L / min, cooled to room temperature, and pulverized the material to obtain a carbon-coated solid electrolyte material.

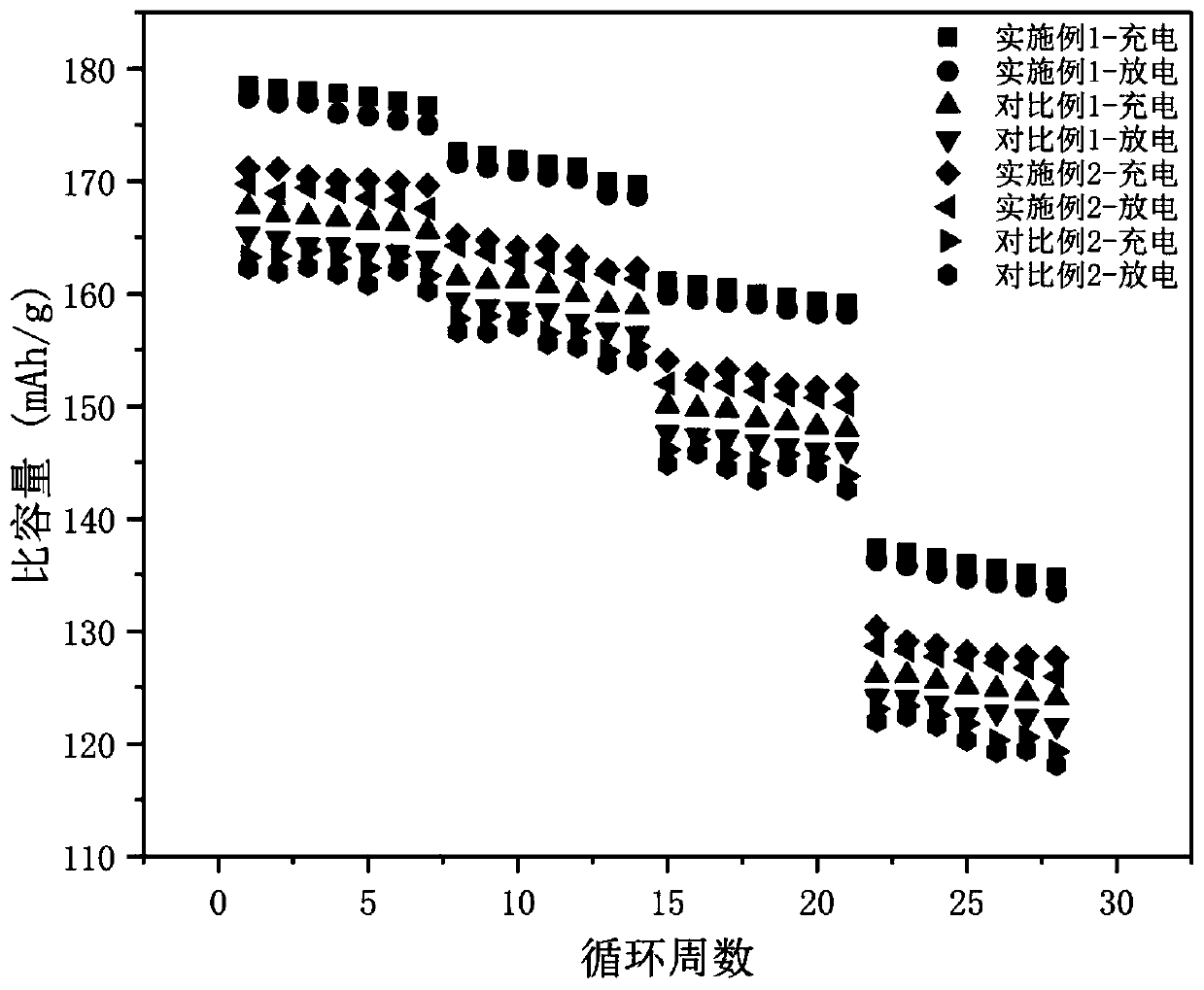

[0063] The carbon-coated solid-state electrolyte material is added in the ratio of 5wt% to 90wt% positive electrode material lithium iron phosphate, and with 3wt% binder polyvinylidene fluoride (PVDF) and 2wt% conductive additive conductive carbon black ( SP) was prepared into a slurry and coated on an aluminum foil to obtain a positive electrode sheet, which was assembled into a half-cell to test the rate performance of the ma...

Embodiment 3

[0070] The LISICON type solid electrolyte material Li with a particle size of 200nm 8 Zr(PO 4 ) 4Place it in the deposition equipment, and use nitrogen as a protective gas with a flow rate of 0.2L / min; heat up to 700°C at a rate of 3°C / min; feed acetylene gas as a carbon source with a flow rate of 1L / min for vapor-phase coating deposition Cool to room temperature after 4 hours to obtain a carbon-coated solid electrolyte material. The Raman spectrum obtained by the Raman spectrum test is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com