Crystal pulling furnace with replaceable furnace cavity

A technology for pulling furnaces and furnace chambers, applied in the field of crystal growth equipment, can solve the problems of large stainless steel material consumption, unusable small furnace chambers, energy waste, etc., achieve low energy consumption, reduce water and electricity energy consumption, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

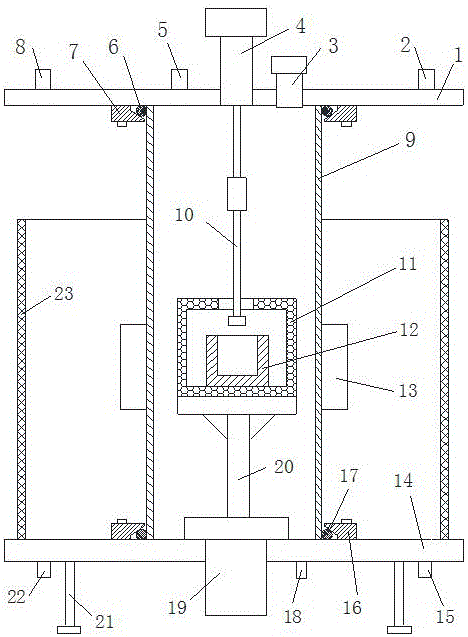

[0027] The present invention is a crystal pulling furnace with a replaceable chamber, the structure of which is as follows: figure 1 shown. Same as the existing pulling furnace, it also includes a furnace cavity, a rotary lifting weighing unit 4, a thermal insulation field 11 and a crucible 12. , tungsten-molybdenum crucible, etc.) placed in the thermal insulation field 11, the thermal insulation field 11 provides the required thermal field for crystal growth, and adopts thermal insulation materials such as zirconia, alumina, graphite or carbon felt. The weighing unit 4 on the rotating and pulling is placed above the furnace cavity, and the seed crystal rod 10 is placed in the furnace cavity and connected with the weighing unit 4 for rotating and pulling. The rotating lifting weighing unit 4 adopts an existing general structure, and is provided with a high-precision weighing sensor, a pulling actuator and a rotating actuator. Accurate pulling and stable rotation for crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com