Sustained release device for growing of SiC single crystals with PVT (physical vapor transport) method

A silicon carbide single crystal, silicon carbide technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of Si loss, high Si vapor pressure, affecting growth components and temperature field stability, etc. The cost of raw materials, the effect of improving the quality of crystal growth and increasing the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

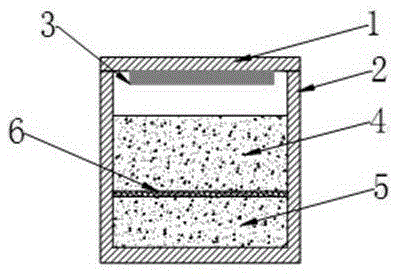

[0015] Such as figure 1 The device for growing silicon carbide single crystal sustained release by the PVT method includes a crucible 2 made of graphite, a crucible cover 1 is fastened on the crucible 2, a seed crystal 3 is fixed on the inner side of the crucible cover 1, and a crucible 2 is provided with The separator 6, the separator 6 is made of graphite, and several holes are arranged on the separator 6 for connecting the upper layer silicon carbide powder source 4 and the lower layer silicon carbide powder source 5 . Preferably, the partition 6 is arranged at a distance of 1 / 3 from the bottom of the crucible 2, that is, at the high temperature zone of the crucible, the temperature of this high temperature zone is higher than that of other zones in the crucible, and the temperature in this high temperature zone is above the sublim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com