Sapphire crystal growth furnace having three heaters

A sapphire crystal, three heater technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems affecting the consistency of crystal growth and process stability, difficult to adjust, high labor costs and management costs, and achieve The effect of shortening production cycle, improving yield and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

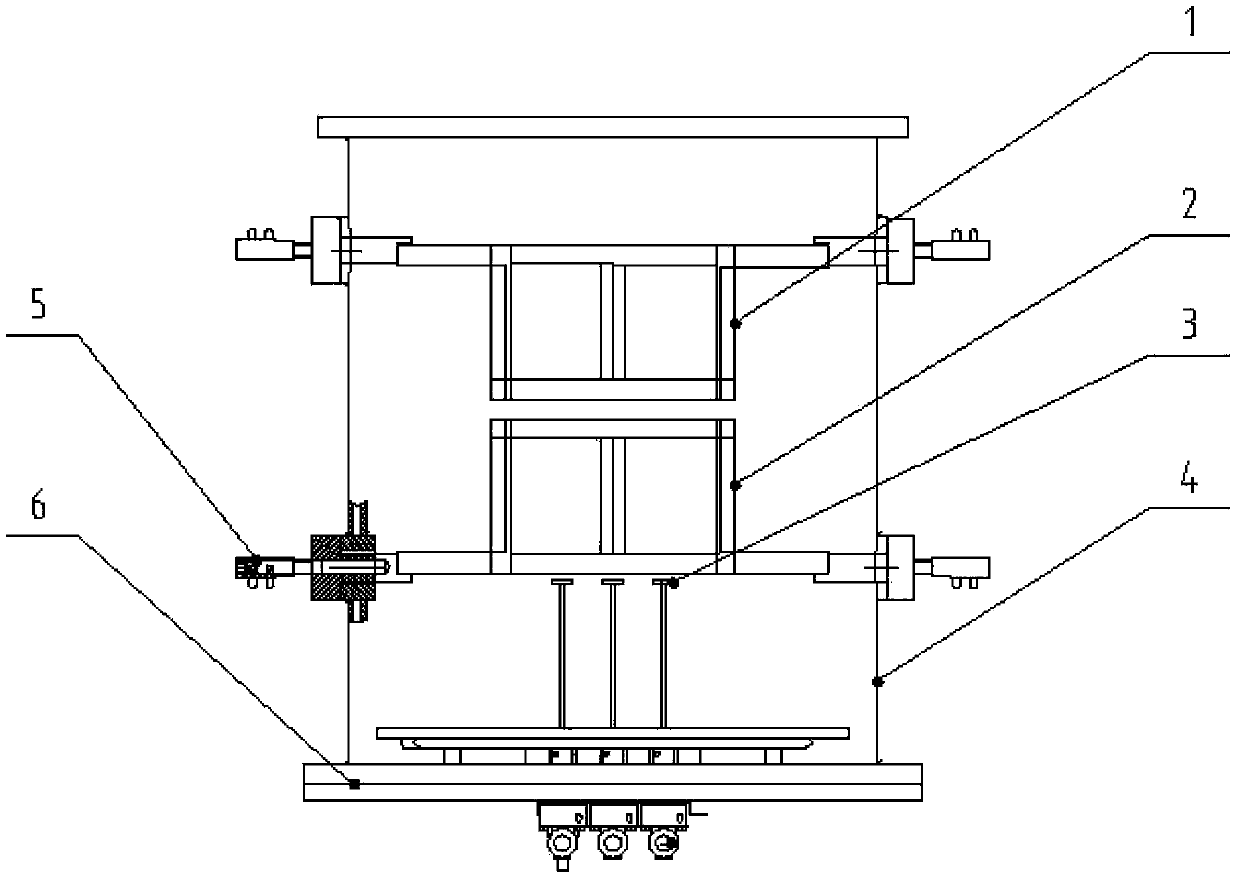

[0017] figure 1 A sapphire crystal growth furnace with three heaters includes three heaters, namely an upper heater 1 , a middle heater 2 and a lower heater 3 . The upper heater 1 and the middle heater 2 are vertically installed on the furnace cylinder 4 top and the middle electrode 5 of the sapphire crystal growth furnace respectively, and the lower heater 3 is vertically installed on the furnace floor 6 electrode 5 of the sapphire crystal growth furnace, And the lower heater 3 can follow the furnace bottom plate 6 to move up and down, which is beneficial to the installation and disassembly of the crucible, and the design of the three heaters makes it possible to install space in the radial and axial directions, which is different from the original birdcage heater. In comparison, it is more conducive to the design of the furnace type with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com