High-light-output bismuth silicate scintillation crystal and preparation method thereof

A technology of scintillation crystals and bismuth silicate, which is applied in the field of materials science, can solve problems such as poor light output effects, achieve the effects of improving growth efficiency and application, increasing light output, and reducing segregation of melt components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Bi with a purity of not less than 99.99% 2 o 3 Powder, SiO 2 Powder and Ta 2 o 5 Dry the powder in a drying oven for 3 hours, and then accurately weigh Bi according to the molar ratio of 2:3 2 0 3 and SiO 2 , mixed, compacted, and then sintered at 850 ° C for 8 hours; the sintered material was cooled and then ground and then mixed with Ta 2 o 5 Powder (Ta 5+ The doping amount is 0.2mol%), mixed evenly again, compacted, and sintered at 900°C for 10 hours to obtain bismuth silicate polycrystalline material;

[0030] Take a BSO single crystal with a crystal orientation of and a size of Φ10×50mm as a seed crystal, put the bismuth silicate polycrystalline material and the seed crystal into a platinum crucible, and then use the vertical solidification method for crystal growth: first use 14 hours to Furnace growth at 1130°C, and then keep it warm for 10 hours, then gradually lift the downcomer. After the polycrystalline material in the crucible is completely melted,...

Embodiment 2

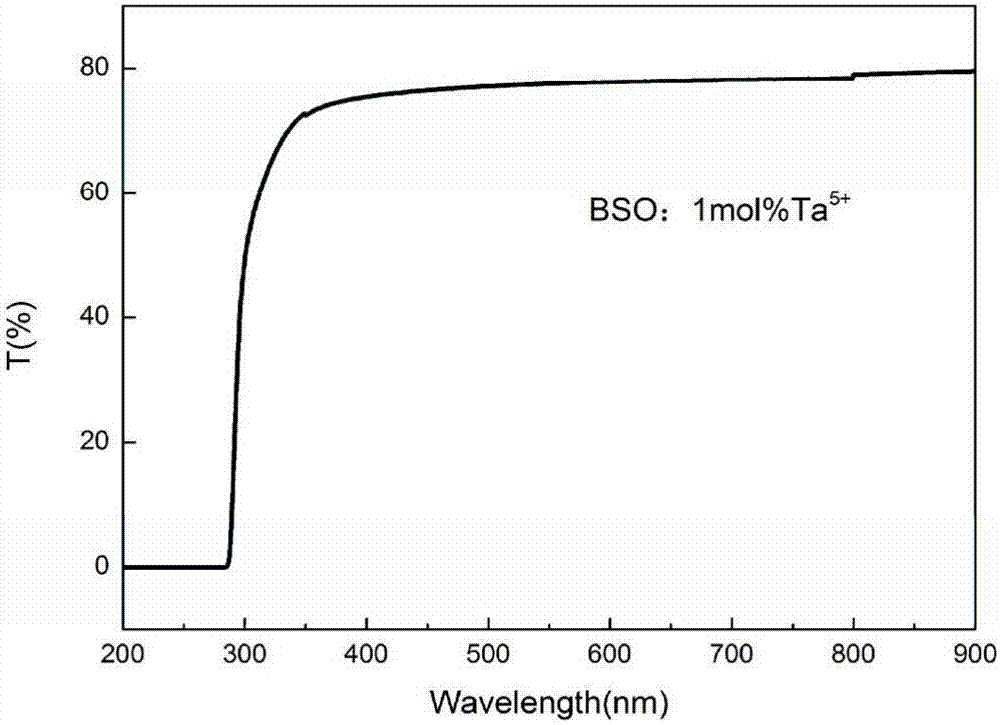

[0033] Bi with a purity of not less than 99.99% 2 o 3 Powder, SiO 2 Powder and Ta 2 o 5 Dry the powder in a drying oven for 3 hours, and then accurately weigh Bi according to the molar ratio of 2:3 2 0 3and SiO 2 , mixed, compacted, and then sintered at 850 ° C for 8 hours; the sintered material was cooled and then ground and then mixed with Ta 2 o 5 Powder (Ta 5+ The doping amount is 1mol%), mixed evenly again, compacted, and sintered at 900°C for 10 hours to obtain bismuth silicate polycrystalline material;

[0034] Take a BSO single crystal with a crystal orientation of and a size of Φ10×50mm as a seed crystal, put the bismuth silicate polycrystalline material and the seed crystal into a platinum crucible, and then use the vertical solidification method for crystal growth: first use 14 hours to Furnace growth at 1130°C, and then keep it warm for 10 hours, then gradually lift the downcomer. After the polycrystalline material in the crucible is completely melted, lo...

Embodiment 3

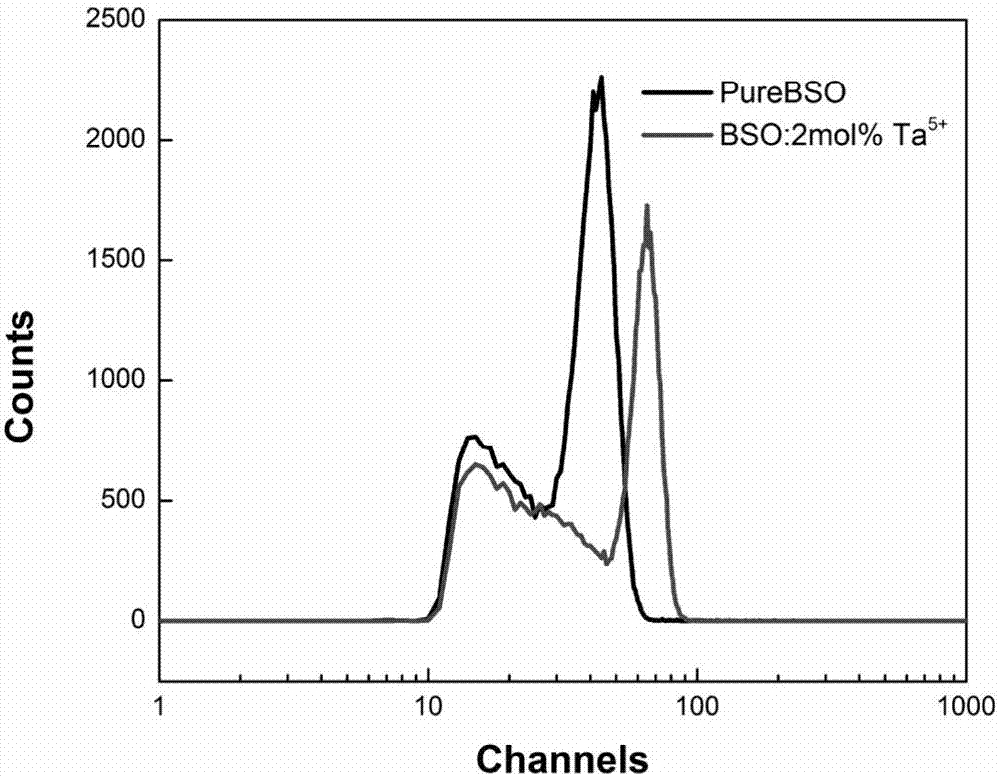

[0037] Bi with a purity of not less than 99.99% 2 o 3 Powder, SiO 2 Powder and Ta 2 o 5 Dry the powder in a drying oven for 3 hours, and then accurately weigh Bi according to the molar ratio of 2:3 2 0 3 and SiO 2 , mixed, compacted, and then sintered at 850 ° C for 8 hours; the sintered material was cooled and then ground and then mixed with Ta 2 o 5 Powder (Ta 5+ The doping amount is 2mol%), mixed evenly again, compacted, and sintered at 900°C for 10 hours to obtain bismuth silicate polycrystalline material;

[0038] Take a BSO single crystal with a crystal orientation of and a size of Φ10×50mm as a seed crystal, put the bismuth silicate polycrystalline material and the seed crystal into a platinum crucible, and then use the vertical solidification method for crystal growth: first use 14 hours to Furnace growth at 1130°C, and then keep it warm for 10 hours, then gradually lift the downcomer. After the polycrystalline material in the crucible is completely melted, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com