Method of preparing multi-wall carbon nano-tube by using polymer as raw material

A technology of multi-walled carbon nanotubes and polymers, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the complex preparation process of arc discharge method, the diameter of carbon nanotubes is not neat enough, and the performance of carbon nanotubes is affected. problems, to achieve the effect of scientific and reasonable preparation method, less energy consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

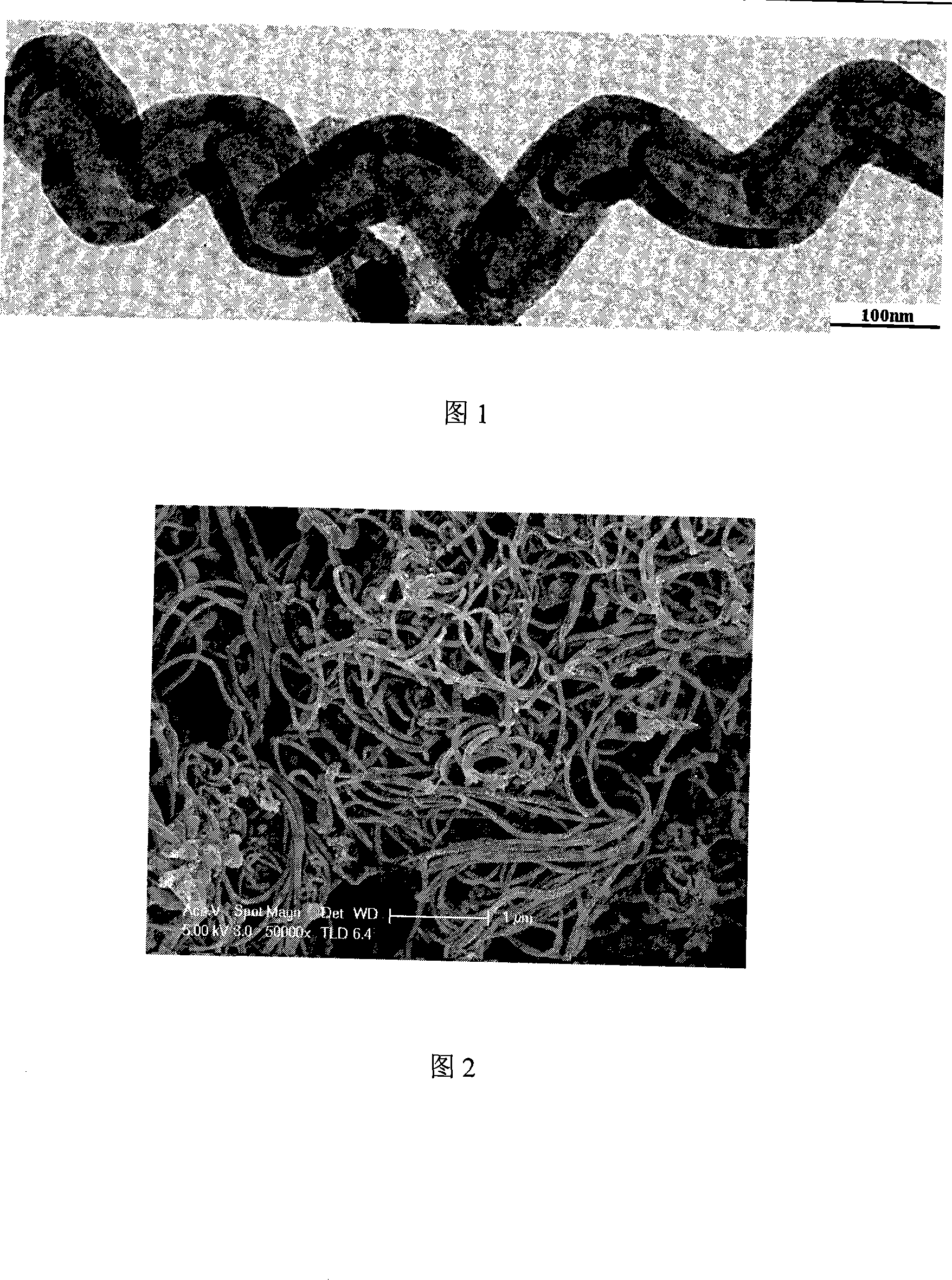

[0019] Using polyethylene as raw material and ferrocene as catalyst, accurately weigh 2.00g of dry polyethylene, 0.80g of maleic anhydride grafted polyethylene, and 0.060g of ferrocene, and mix them evenly; put the mixed solids into an autoclave, React at 700°C for 15 hours. After the reaction, cool the reactor to room temperature, take out the reaction product, wash with acid to remove the catalyst, and dry to obtain a sample. FIG. 1 is a transmission electron micrograph of the helical carbon nanotubes obtained in this example. It can be seen from Figure 1 that at 700°C, ferrocene is used as a catalyst to catalyze the decomposition of polyethylene, and the helical carbon nanotubes obtained by catalyzing the decomposition of polyethylene are parallel bamboo-shaped structures with a diameter of about 80 nanometers.

Embodiment 2

[0021] Using polyethylene as raw material and metallic nickel as catalyst, accurately weigh 2.00g of dry polyethylene, 0.50g of maleic anhydride grafted polyethylene, and 0.10g of metallic nickel, and mix them evenly; The reaction was carried out at high temperature for 10 hours. After the reaction, the reactor was cooled to room temperature, the reaction product was taken out, the catalyst was removed by pickling, and the sample was dried.

Embodiment 3

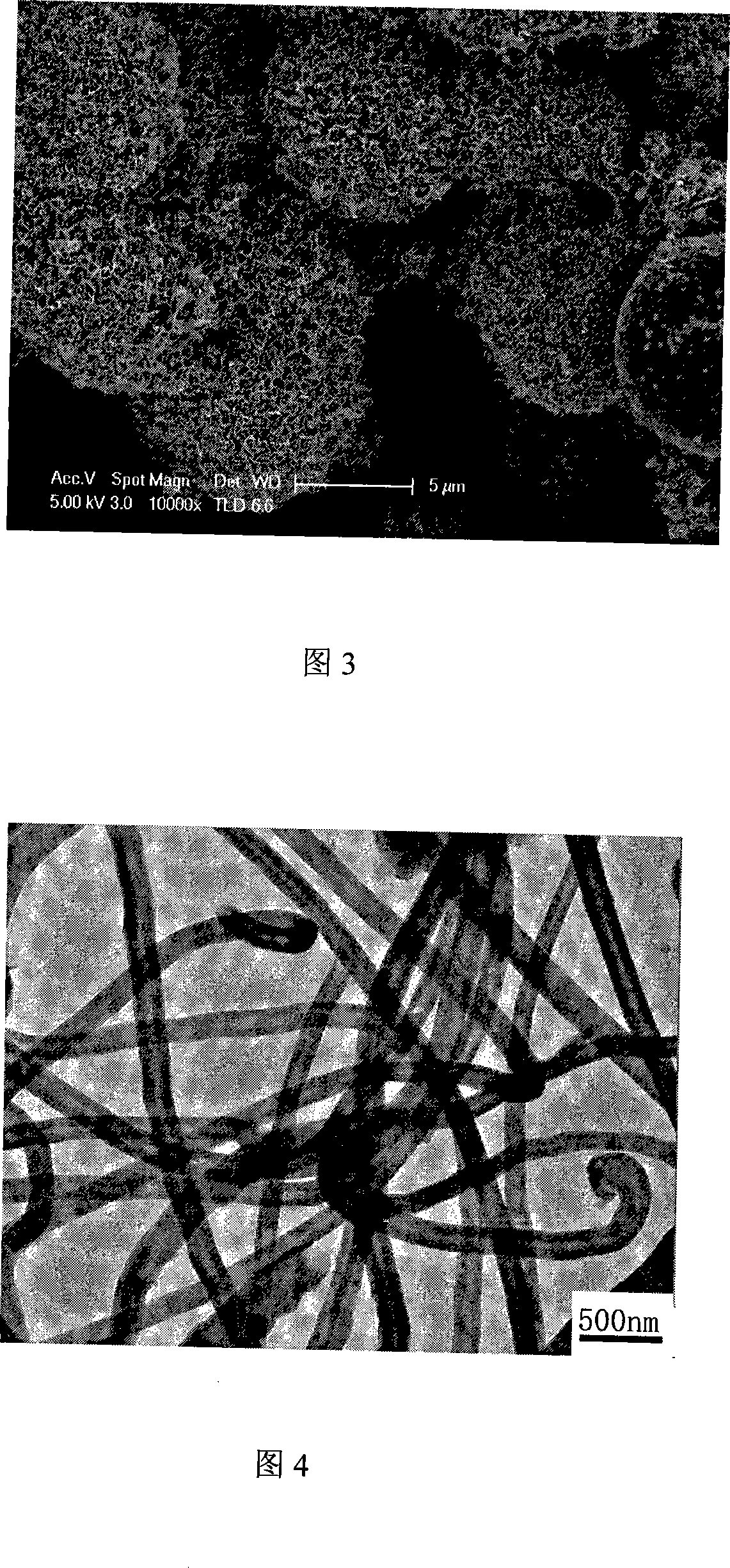

[0023] Using polypropylene as a raw material and ferrocene as a catalyst, accurately weigh 2.00 g of dry polypropylene, 0.50 g of maleic anhydride grafted polypropylene, and 0.10 g of ferrocene, and mix them uniformly; put the mixed solids into an autoclave, React at 600°C for 25 hours. After the reaction, cool the reactor to room temperature, take out the reaction product, pickle to remove the catalyst, and dry to obtain a sample. FIG. 2 is a field emission electron micrograph of the carbon nanotubes obtained in this example. It can be seen from Figure 2 that at 600°C, ferrocene is used as a catalyst to catalyze the decomposition of polypropylene to obtain mainly carbon nanotubes, the length of which is several microns to tens of microns, and the diameter is between 40-70 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com