Large-scale production method for chemical vapor deposition (CVD) graphene film

A graphene film and production method technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as the limited number of samples hanging, and achieve the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of large-scale production method of CVD deposited graphene film, concrete operation steps are as follows:

[0040] 1) sample loading

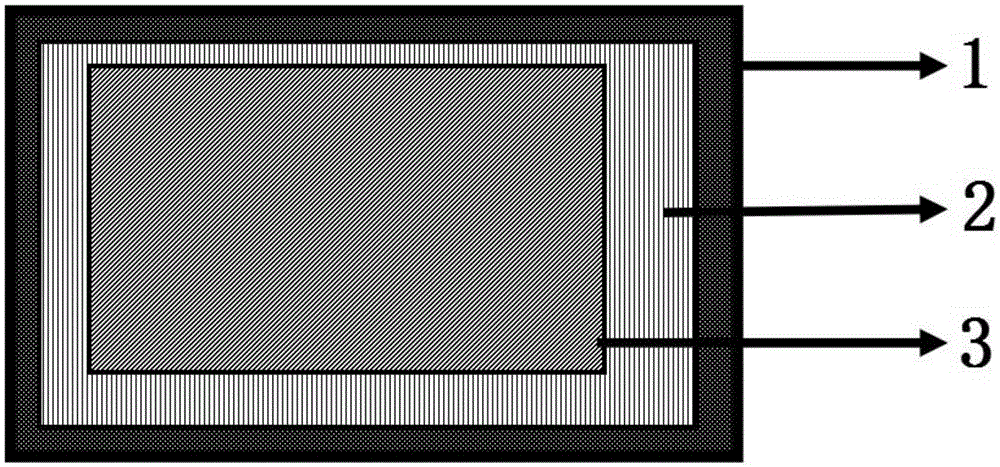

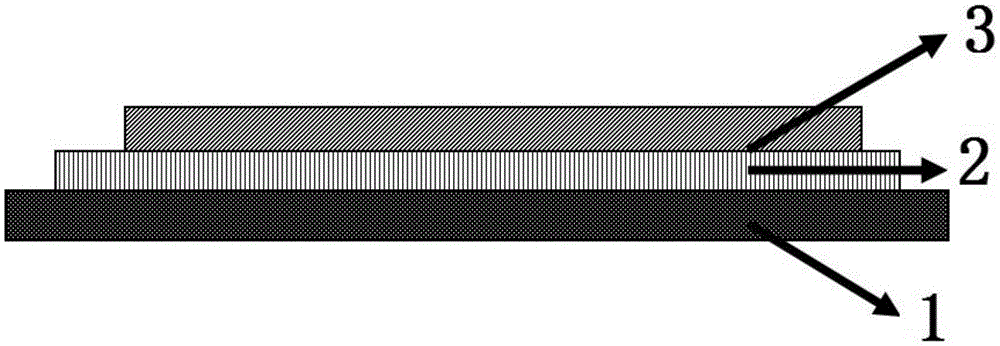

[0041] Press as figure 1 and 2 Shown is a schematic diagram of a separate loading unit, the isolation layer 2 and the metal base 3 are placed alternately, that is, first place a layer of isolation layer 1 on the pallet 1, and then place the metal base 2, the placement method is "isolation layer 2 + metal base 3 ” is the basic unit, which is repeated in turn. In this embodiment, the metal base adopts copper foil with a size of 20cm*30cm, and stacks up to 100 layers of copper foil;

[0042] 2) grow

[0043] a. Put the sample into the process chamber, close the process chamber, evacuate to below 10mTorr, and raise the temperature to 1000°C;

[0044] b. Hydrogen annealing at a flow rate of 500 sccm for 30 minutes;

[0045] c. Press H 2 :CH 4 =500sccm: 500sccm ratio was grown at 1000°C for 60min;

[0046] 3) cooling

[0047] A...

Embodiment 2

[0054]A kind of large-scale production method of CVD deposited graphene film, concrete operation steps are as follows:

[0055] 1) sample loading

[0056] Press as figure 1 and 2 Shown is a schematic diagram of a separate loading unit, the isolation layer 2 and the metal base 3 are placed alternately, that is, first place a layer of isolation layer 1 on the pallet 1, and then place the metal base 2, the placement method is "isolation layer 2 + metal base 3 ” is the basic unit, and the cycle continues in turn. The metal base of this embodiment uses copper foil with a size of 20cm*30cm, and stacks up to 90 layers of copper foil;

[0057] 2) grow

[0058] a. Put the sample into the process chamber, close the process chamber, evacuate to below 10mTorr, and raise the temperature to 1000°C;

[0059] b. Hydrogen annealing at a flow rate of 500 sccm for 30 minutes;

[0060] c. Press H 2 :CH 4 =400sccm:600sccm ratio was grown at 1000°C for 60min;

[0061] 3) cooling

[0062] A...

Embodiment 3

[0069] A kind of large-scale production method of CVD deposited graphene film, concrete operation steps are as follows:

[0070] 1) sample loading

[0071] Press as figure 1 and 2 Shown is a schematic diagram of a separate loading unit, the isolation layer 2 and the metal base 3 are placed alternately, that is, first place a layer of isolation layer 1 on the pallet 1, and then place the metal base 2, the placement method is "isolation layer 2 + metal base 3 ” is the basic unit, and the cycle continues in turn. The metal base of this embodiment uses copper foil with a size of 40cm*60cm, and stacks up to 70 layers of copper foil;

[0072] 2) grow

[0073] a. Put the sample into the process chamber, close the process chamber, evacuate to below 10mTorr, and raise the temperature to 1200°C;

[0074] b. Annealing with argon gas at a flow rate of 500 sccm for 30 minutes;

[0075] c. Press Ar:CH 4 =500sccm:1000sccm ratio was grown at 1200°C for 90min;

[0076] 3) cooling

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com