InGaN/GaN quantum well grown on ScMgAlO4 substrate and preparation method of InGaN/GaN quantum well

A magnesium scandium aluminate, quantum well technology, applied in electrical components, circuits, semiconductor devices and other directions, can solve the problem of unfavorable high-quality GaN thin film growth, high-performance GaN thin film device industrialization, difficult preparation of large-scale substrates, and substrates. Problems such as poor single crystal quality, to achieve the effect of being conducive to heat dissipation, releasing mismatch stress, and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

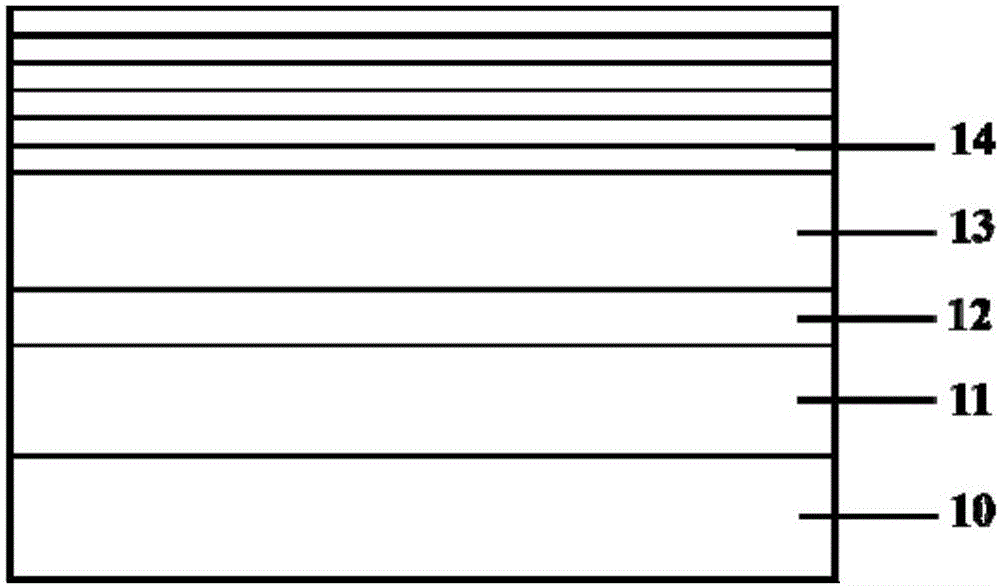

[0036] The preparation method of the InGaN / GaN multiple quantum well grown on the magnesium scandium aluminate substrate of the present embodiment comprises the following steps:

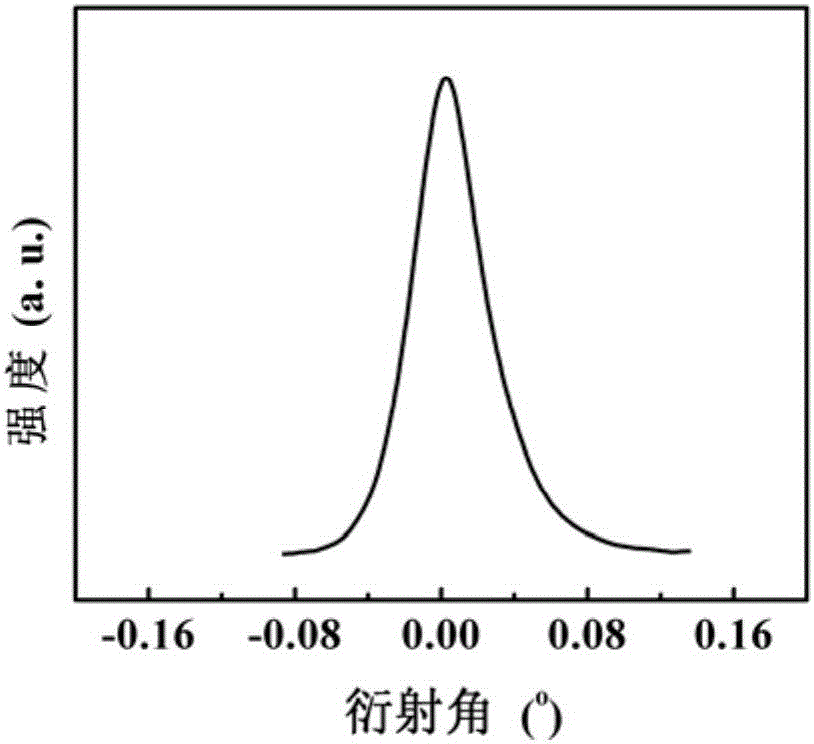

[0037] (1) Selection of the substrate and its crystal orientation: Magnesium aluminate scandium substrate is used, with the (0001) plane offset from the (11-20) plane by 0.5-1° as the epitaxial plane, and the crystal epitaxial orientation relationship is: (0001) of GaN ) plane parallel to ScMgAlO 4 (0001) face; such as figure 1 As shown, the magnesium scandium aluminate substrate used in the present invention has high crystal quality, and the XRD rocking curve half-maximum width (FWHM) value of the (0001) plane is only 20arcsec.

[0038] (2) Substrate annealing treatment, the specific process of the annealing is: the magnesium scandium aluminate substrate is annealed at 600° C. for 1 hour in the molecular beam epitaxy vacuum growth chamber of the substrate to obtain an atomically flat surface;

[003...

Embodiment 2

[0048] The preparation method of the InGaN / GaN multiple quantum well grown on the magnesium scandium aluminate substrate of the present embodiment comprises the following steps:

[0049] (1) Selection of the substrate and its crystal orientation: Magnesium aluminate scandium substrate is used, with the (0001) plane offset from the (11-20) plane by 0.5-1° as the epitaxial plane, and the crystal epitaxial orientation relationship is: (0001) of GaN ) plane parallel to ScMgAlO 4 (0001) face;

[0050] (2) Substrate annealing treatment, the specific process of the annealing is: annealing the magnesium scandium aluminate substrate at 700° C. for 2 hours in the molecular beam epitaxy vacuum growth chamber of the substrate to obtain an atomically flat surface;

[0051] (3) Epitaxial growth of the first GaN buffer layer: the substrate temperature is adjusted to 550°C, and the pressure in the reaction chamber is 4.0×10 by pulsed laser deposition technology. -5 Pa, laser energy density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com