Preparation method of highly stable lead-based organic-inorganic hybrid perovskite nano sheet

A nanosheet and perovskite technology, which is applied in the field of preparation of lead-based organic-inorganic hybrid perovskite nanosheets, can solve the problems of low deposition rate, complicated process, and unstable heavy element lead in chemical vapor deposition. To achieve the effect of avoiding water or air deterioration, avoiding the use of organic solvents, and avoiding excessive equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

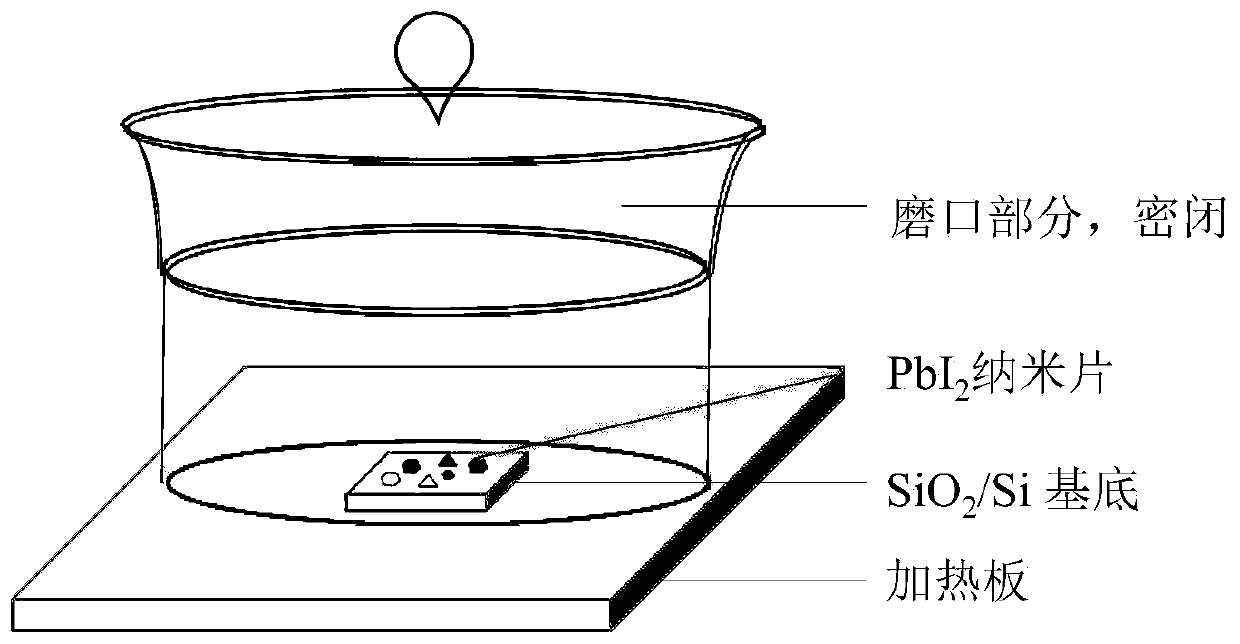

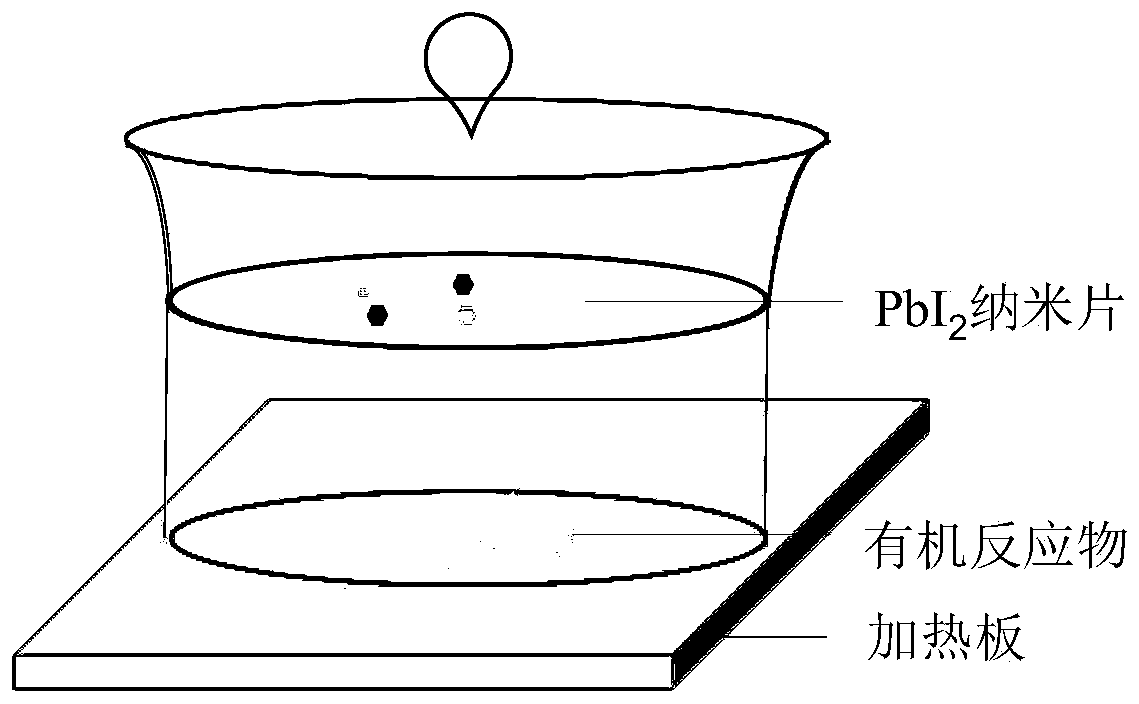

Method used

Image

Examples

preparation example Construction

[0036] Preparation example Preparation of piperazine derivatives

[0037] The preparation method is a typical N-alkylation method, using piperazine hexahydrate and long-chain haloalkane or bromobenzene as raw materials for N-alkylation reaction, the solvent is DMF, and the base is sodium carbonate or triethylamine. The catalyst is sodium iodide, which is reacted at 80-110°C for 10-25 hours, separated and purified by chromatographic column, and the purity is verified by HNMR.

preparation example 1N- 10

[0038] Preparation of Preparation Example 1N-Dodecylpiperazine

[0039] It is obtained by alkylation reaction of piperazine six water. Specifically, 0.1mol piperazine hexahydrate and 0.08mol 1-bromododecane are dissolved in acetone / ethanol (volume ratio 1:1), a condenser is installed, and under stirring conditions, heated to 100°C for reflux reaction for 15 hours, the reaction After the termination, a large amount of white crystals were precipitated. After filtration, recrystallization and silica gel column chromatography, 3 g of the product was obtained, with a melting point of 140° C. and a molecular weight of 254.

preparation example 2N- 10

[0040] Preparation of Preparation Example 2N-Tetradecylpiperazine

[0041] The steps are the same as those in Preparation Example 1, except that 1-bromotetradecane is used instead of 1-bromododecane, and the obtained product is N-tetradecylpiperazine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com