Graphene sapphire substrate suitable for epitaxial growth of III-nitride

A sapphire substrate and graphene technology, applied in the field of materials, can solve the problems of low yield rate, cumbersome operation, lack of dangling bonds in graphene, etc., and achieve the effects of alleviating thermal conductivity, simplifying the growth process, and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

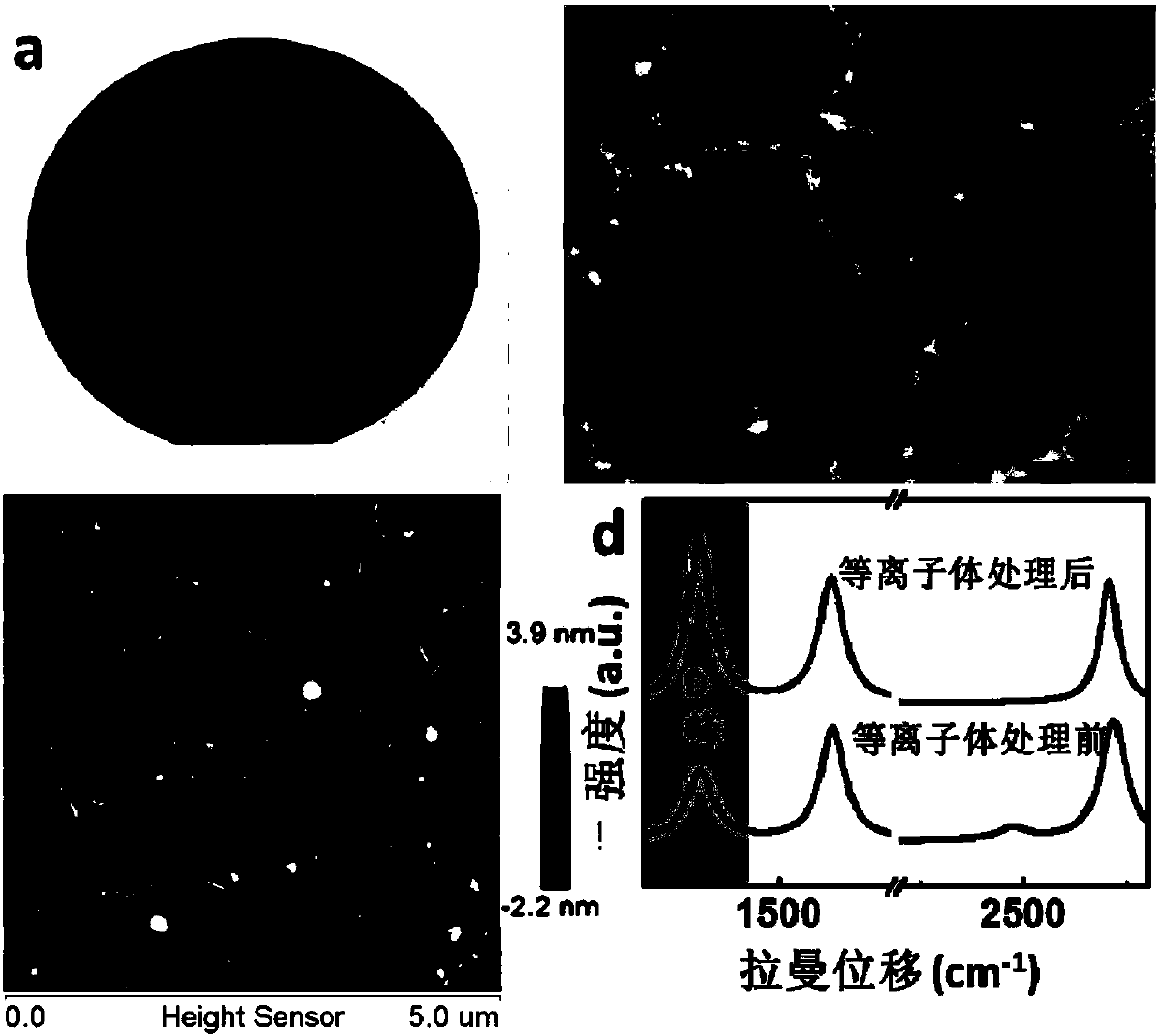

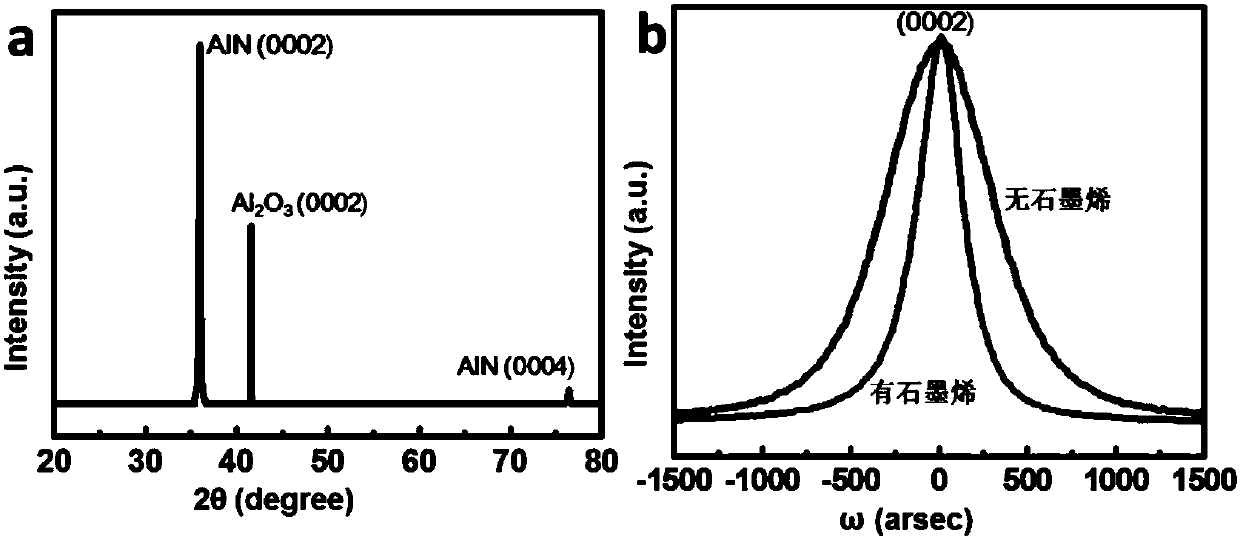

[0068] A method for preparing a novel graphene-sapphire substrate suitable for epitaxial growth of group III nitrides, the steps are as follows:

[0069] (1) Cleaning of the sapphire substrate: The sapphire substrate was ultrasonically cleaned with ultrapure water, isopropanol, and acetone for 5 minutes respectively, and dried with nitrogen gas after cleaning, wherein the ultrasonic power was 90W.

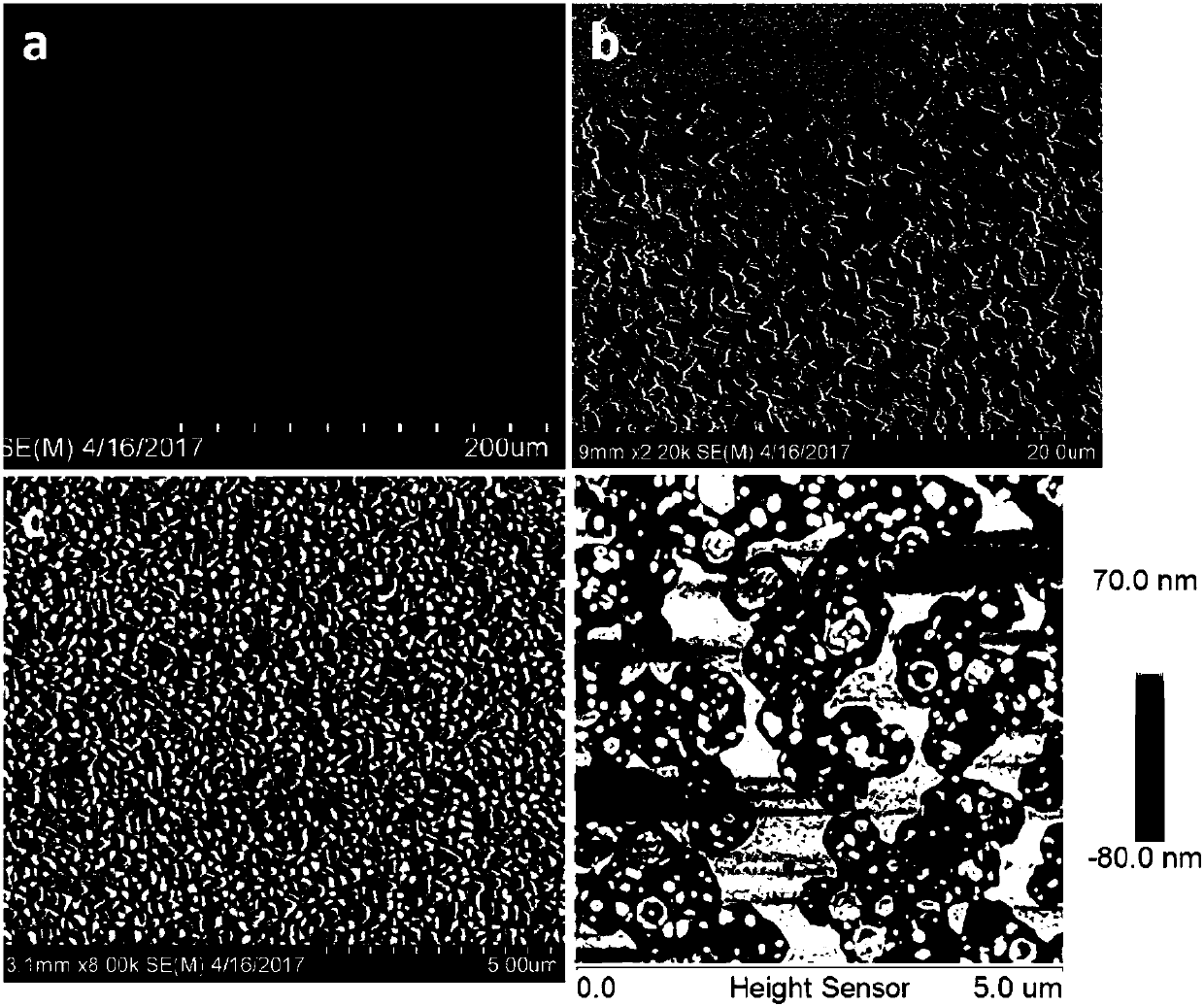

[0070] (2) at high temperature, carry out the chemical vapor deposition of graphene thin film to sapphire substrate: the clean sapphire glass substrate that step (1) obtains is put into APCVD reaction cavity, Ar and H 2 The gas flow meters were set to 500sccm and 100sccm respectively. After the gas scrubbing, the furnace body was heated to 1050°C, and Ar and H were kept during the heating process. 2 The flow rate does not change. After the furnace temperature rises to 1050°C and stabilizes for 15 minutes, turn on the CH 4 The flow meter was set at 20 sccm and the growth time was ...

Embodiment 2

[0083] A method for preparing a novel graphene sapphire substrate for epitaxial growth of group III nitrides, the steps are the same as in Example 1, the difference is that LPCVD is used instead of APCVD, and the deposition environment is a low-pressure environment; the deposition temperature is 1080 ° C; the carrier gas It is a mixed gas composed of argon and hydrogen, wherein the flow ratio of argon to hydrogen is 5:1, specifically, the flow rate of argon is 500 sccm, and the flow rate of hydrogen is 100 sccm; the carbon source is ethanol vapor, and the flow rate is set to 500 sccm , the partial pressure is 250Pa; the deposition time is 1h, and a new graphene sapphire substrate suitable for the epitaxial growth of group III nitrides is also obtained.

Embodiment 3

[0085] In the PECVD, the deposition environment is a low-pressure environment with a pressure of 100 Pa; the deposition temperature is 600° C.; the carbon source is methane, the flow rate is 18 sccm, the power of the plasma generator is 120 W, and the deposition time is 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com