Potassium sodium niobate based single crystal and preparation method thereof

A potassium-sodium niobate-based, single-crystal technology, which is applied in the direction of single-crystal growth, single-crystal growth, chemical instruments and methods, etc., can solve problems such as small single-crystal size, achieve small segregation, uniform distribution of components, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

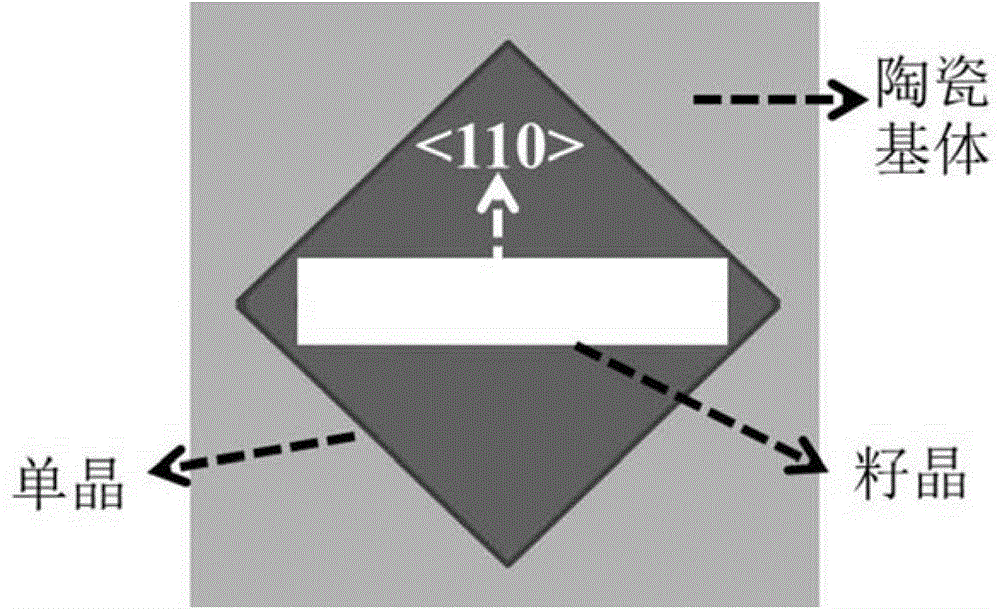

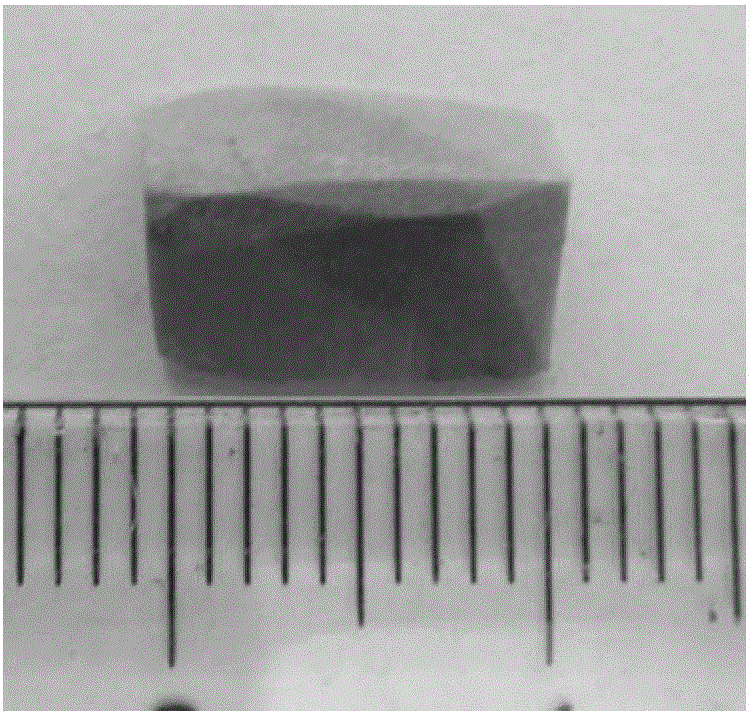

[0039] According to the chemical formula (K 0.45 Na 0.55 ) 0.98 Li 0.02 NbO 3 The K:Na:Li:Nb molar ratio is 0.441:0.539:0.02:1 equipped with K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 Raw materials, using absolute ethanol as a ball milling medium, and planetary ball milling for 6 hours to obtain slurry. After the slurry was dried at 100°C for 8 hours, it was pre-fired at 850°C for 5 hours to synthesize powder raw materials, and 0.5mol% MnO was added 2 , using absolute ethanol as the ball milling medium to perform high-energy ball milling for 2 hours to obtain a slurry. The slurry after high-energy ball milling was dried at 100°C for 12 hours, and then KTaO in the direction with a size of 10mm×10mm×0.5mm 3 The single crystal seed crystal is buried in the dried powder, and uniaxially pressed to form a φ40mm disc, followed by 200MPa cold isostatic pressing to obtain a ceramic green body. Put the ceramic green body into the crucible, the inside of the crucible is ...

Embodiment 2

[0041] According to the chemical formula (K 0.45 Na 0.55 ) 0.96 Li 0.04 NbO 3 The K:Na:Li:Nb molar ratio is 0.432:0.528:0.04:1 equipped with K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 Raw materials, using absolute ethanol as a ball milling medium, and planetary ball milling for 6 hours to obtain slurry. After the slurry was dried at 100°C for 8 hours, it was pre-fired at 850°C for 5 hours to synthesize powder raw materials, and 0.5mol% MnO was added 2 , using absolute ethanol as the ball milling medium to perform high-energy ball milling for 2 hours to obtain a slurry. The slurry after high-energy ball milling was dried at 100°C for 12 hours, and then KTaO in the direction with a size of 10mm×10mm×0.5mm 3 The single crystal seed crystal is buried in the dried powder, and uniaxially pressed to form a φ40mm disc, followed by 200MPa cold isostatic pressing to obtain a ceramic green body. Put the ceramic green body into the crucible, the inside of the crucible is ...

Embodiment 3

[0043] According to the chemical formula (K 0.45 Na 0.55 ) 0.94 Li 0.06 NbO 3 The K:Na:Li:Nb molar ratio is 0.423:0.517:0.06:1 equipped with K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 Raw materials, using absolute ethanol as a ball milling medium, and planetary ball milling for 6 hours to obtain slurry. After the slurry was dried at 100°C for 8 hours, it was pre-fired at 850°C for 5 hours to synthesize powder raw materials, and 0.5mol% MnO was added 2 , using absolute ethanol as the ball milling medium to perform high-energy ball milling for 2 hours to obtain a slurry. The slurry after high-energy ball milling was dried at 100°C for 12 hours, and then KTaO in the direction with a size of 10mm×10mm×0.5mm 3 The single crystal seed crystal is buried in the dried powder, and uniaxially pressed to form a φ40mm disc, followed by 200MPa cold isostatic pressing to obtain a ceramic green body. Put the ceramic green body into the crucible, the inside of the crucible is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com