Zinc selenide single crystal growing method and zinc selenide single crystal growing container

A growth method, zinc selenide technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of high cost, complex growth steps of zinc selenide single crystal, etc., achieve small stress, ensure single nucleus growth, The effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

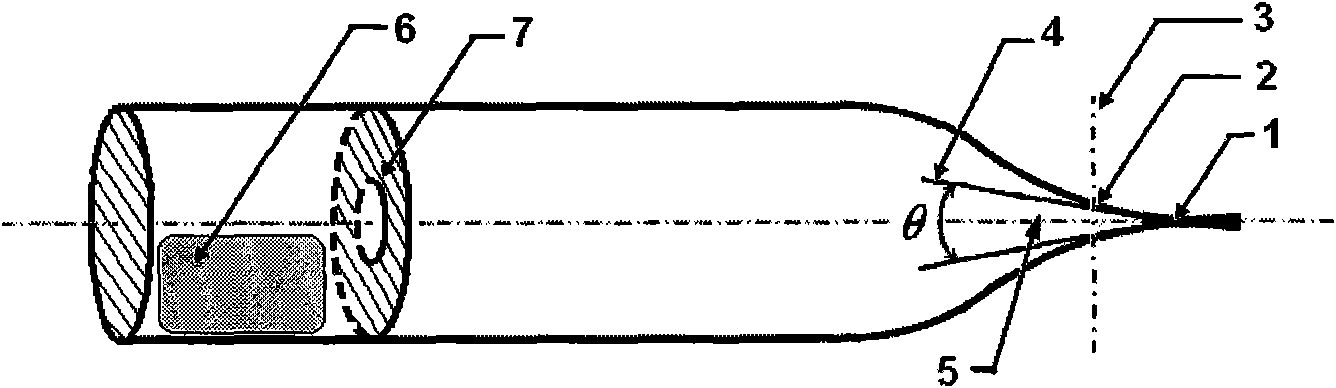

[0030] This embodiment prepares the zinc selenide single crystal that size is 12 * 10 * 8mm, uses the ampoule (such as figure 1 As shown), the ampoule is placed horizontally in the tube furnace, consisting of a Φ16×100mm quartz tubular body, which is divided into a growth area and a raw material area. The shape of the end of the growth zone is a cone, and the length of the cone is 25 mm. The centerline of the cone is coaxial with the centerline of the ampoule, called the central axis. On the cross-section passing through the central axis of the growth zone of the ampoule, the two elliptical arcs that constitute the cone intersect with a straight line that is 9mm away from the vertebral point on the axis, and the cone angle θ formed by the two tangents passing through this intersection is 25°; There is a ring-shaped quartz baffle in the zone, the diameter of the hole in the middle of the baffle is 6mm; the quartz baffle is perpendicular to the ampoule wall, 20mm away from the ...

Embodiment 2

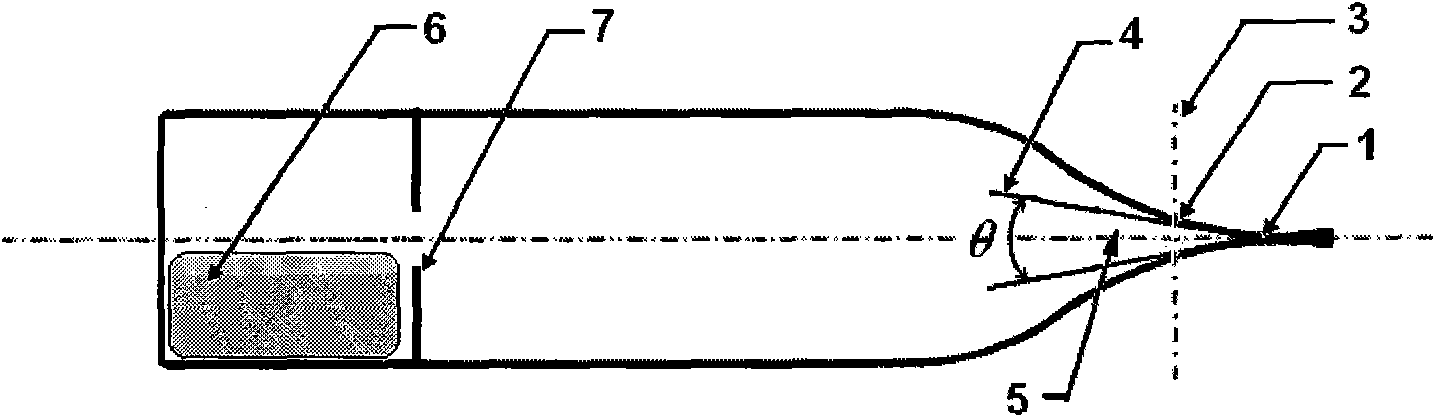

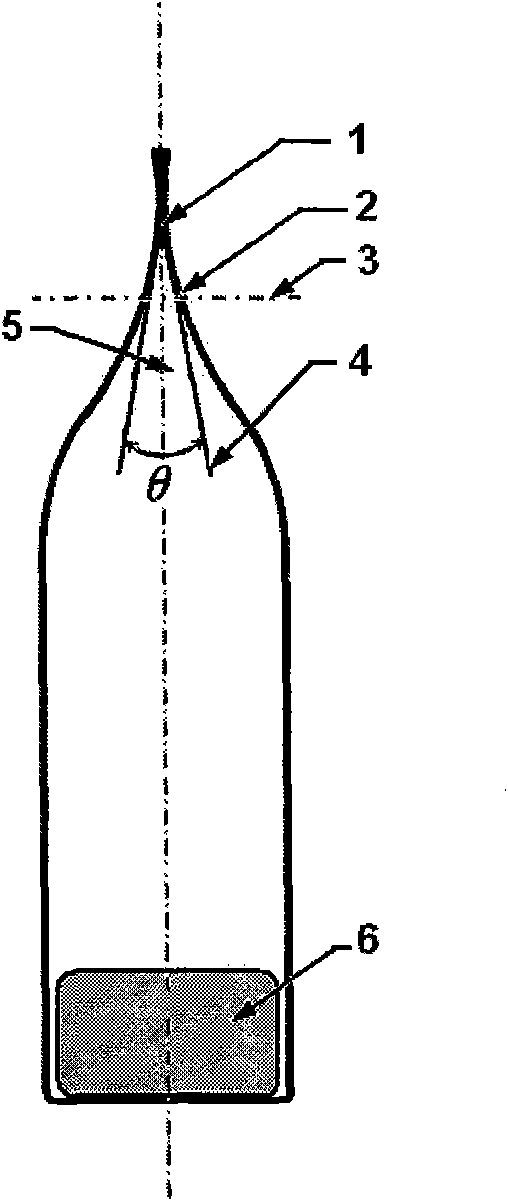

[0047] This embodiment prepares a single crystal of zinc selenide with a size of 13×8×8mm, and uses an ampoule placed vertically to grow a single crystal of zinc selenide, such as figure 2 shown. The ampoule is vertically placed in the tube furnace. The ampoule is composed of a Φ16×150mm quartz tubular body, which is divided into a growth area and a raw material area. The end of the growth area is a cone with a length of 30mm. It passes through the ampoule growth area On the cross-section of the central axis, the two arcs forming the cone intersect at two points the straight line 10mm away from the vertebral point on the central axis, and the cone angle θ formed by the two tangents of the arc passing through these two points is 18°.

[0048] The technique of the present embodiment is according to the following steps successively:

[0049] 1. To clean the ampoules:

[0050] The cleaning process adopts a combination of comprehensive cleaning, strong hydrogen-oxygen flame baki...

Embodiment 3

[0064] This embodiment prepares a single crystal of zinc selenide with a size of 16×8×10mm, using an ampoule such as figure 2 As shown, the ampoule is vertically placed in the tube furnace. The ampoule is composed of a Φ20×120mm quartz tubular body, which is divided into a growth area and a raw material area. The end of the growth area is a cone, and the length of the cone is 25mm. In the ampoule On the cross-section of the growth zone passing through the central axis, the two arcs forming the cone intersect at two points with a straight line 12 mm away from the vertebral point on the central axis, and the cone angle θ formed by the tangent of the two points is 20°.

[0065] The technique of the present embodiment is according to the following steps successively:

[0066] 1. To clean the ampoules:

[0067] The cleaning process adopts a combination of comprehensive cleaning, strong hydrogen-oxygen flame baking and annealing, including:

[0068] (1) Comprehensive cleaning

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com