Growing method for carbon-doped sapphire crystal

A growth method and crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as difficulty in ensuring uniform distribution of C, difficulty in obtaining uniform quality, low effective atomic number, etc., and achieve excellent thermoluminescence Performance, good crystal quality, high sensitivity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

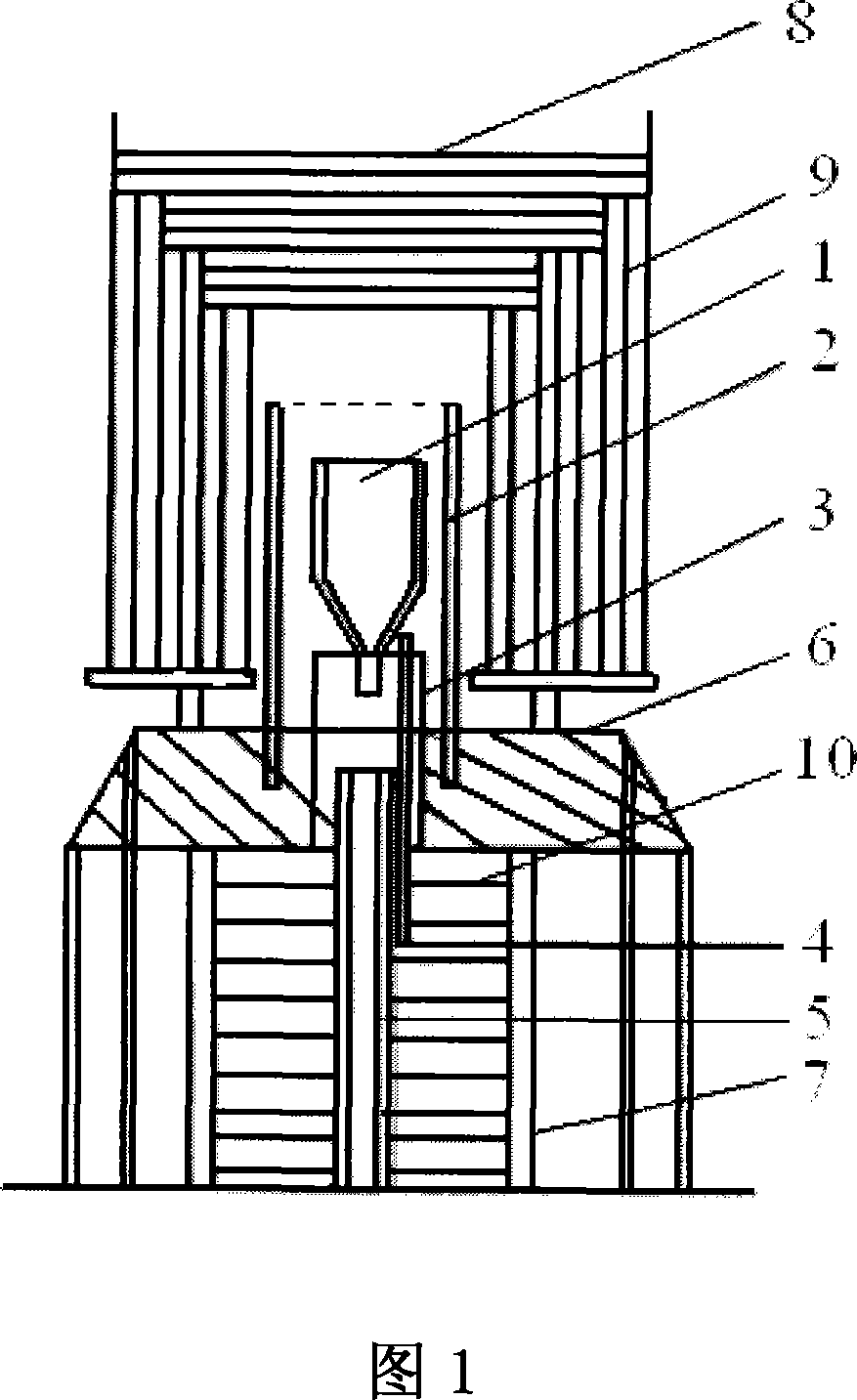

[0025] Example 1: α-Al with a C doping amount of 5000ppm 2 O 3 : C crystal growth

[0026] Weigh 500 grams of α-Al 2 O 3 Mix with 2.50 grams of graphite, which is 5000 ppm, in a mixer for 24 hours, and pack them in a fresh-keeping bag for later use. Put the R(0112) direction oriented seed crystal into the seed crystal groove at the tail of the molybdenum crucible of φ50×80mm, put the prepared powder into the crucible evenly, and cover the crucible lid. Put the side insulation screen so that the crucible is in the center of the cylinder, then cover the top insulation screen in turn, and finally cover the bell jar. Turn on the mechanical pump and vacuum to 5×10 -3 Pa, turn on the power supply and continue to heat up to 2353K, keep the temperature constant for 1 hour, then cool down to room temperature at a rate of 5°C / hour, open the furnace cover, and take out the crystals.

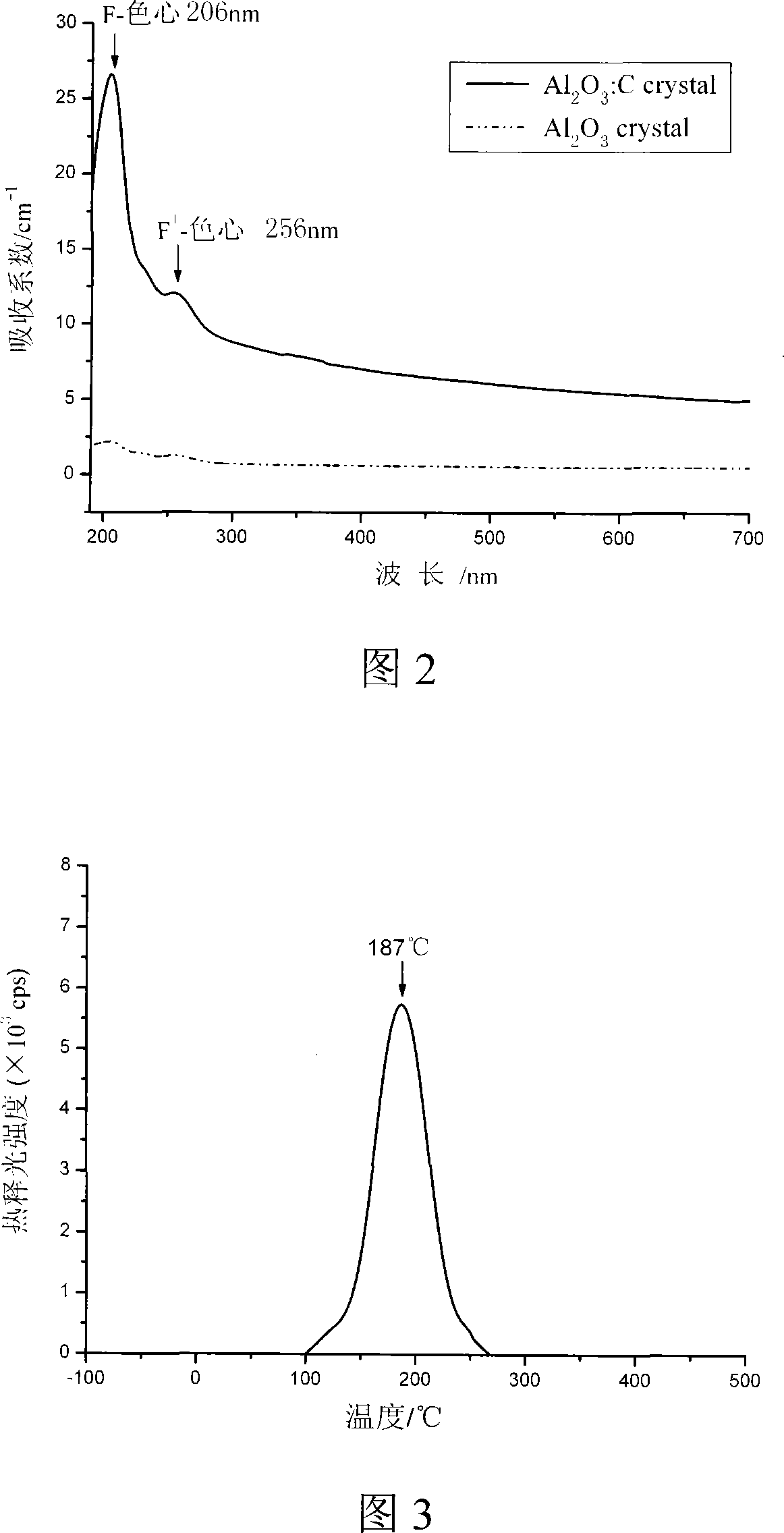

[0027] After inspection, the α-Al of this embodiment 2 O 3 : C crystals are intact, without obvious inclusio...

Embodiment 2

[0028] Example 2: α-Al with 100 ppm C doping 2 O 3 : C crystal growth

[0029] Except that the added graphite C is 100 ppm, and the temperature is lowered to room temperature at a rate of 3° C. / hour to grow crystals, other ingredients and growth steps are the same as in Example 1. Α-Al from growth 2 O 3 :C crystal, the crystal structure is complete, no obvious inclusions and bubbles appear. The intensity of the F color center of the crystal at 206nm and the thermoluminescence intensity at 187℃ are relatively reduced, but the position of the thermoluminescence peak at 187℃ does not change.

Embodiment 3

[0030] Example 3: α-Al with a C doping amount of 2500ppm 2 O 3 : C crystal growth

[0031] Except that the added graphite C is 2500 ppm, the temperature is lowered to room temperature at a rate of 4° C. / hour to grow crystals, and other ingredients and growth steps are the same as in Example 1. Α-Al from growth 2 O 3 : C crystal, complete crystal structure, no obvious inclusions and bubbles, with α-Al 2 O 3 :C crystal is located at the characteristic thermoluminescence peak of 187℃, and the F color center intensity at 206nm is larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com