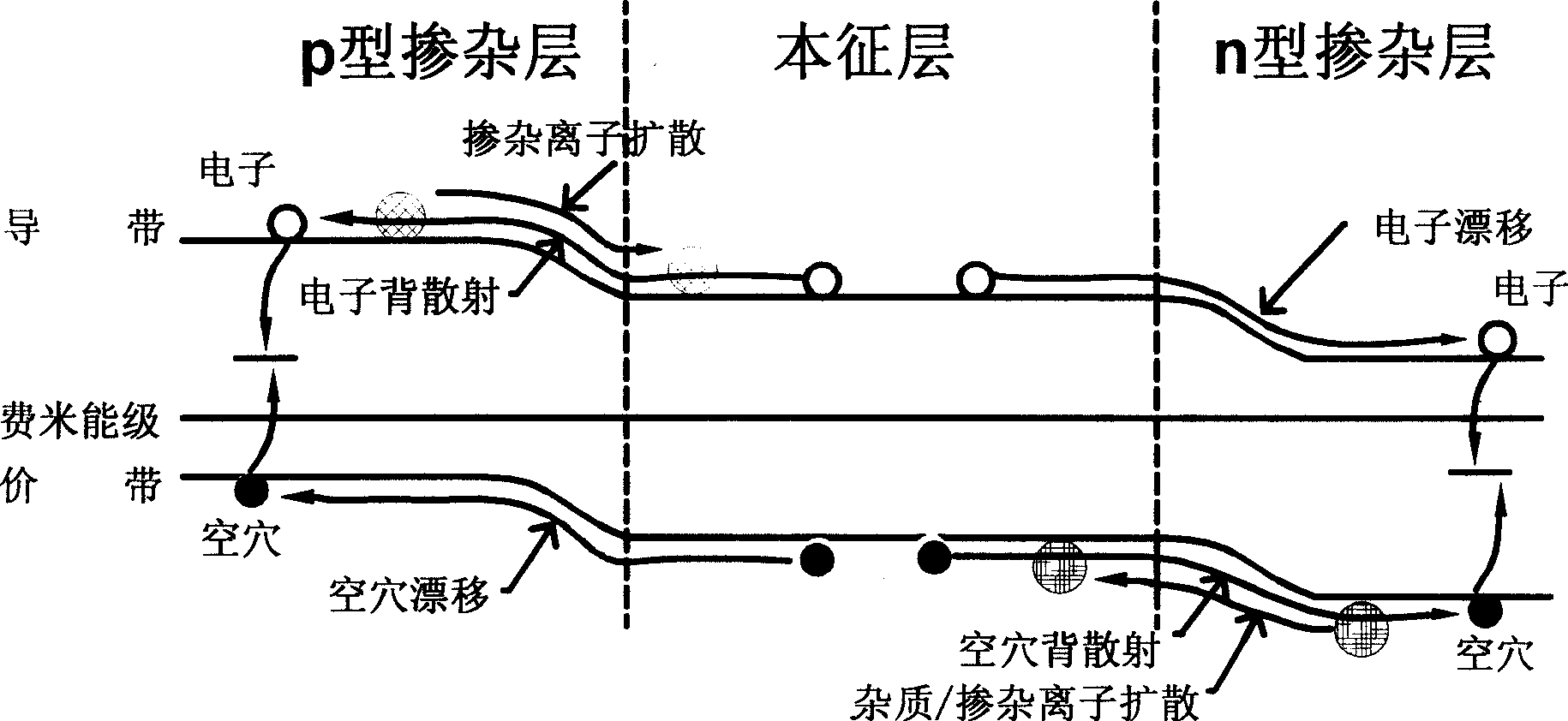

Double-layer doping-layer silicon-based film solar cell

A silicon-based thin film, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the steps and complexity of the battery manufacturing process, the influence of the overall performance of the battery, and the inability to suppress the particle exchange. Improve fill factor and initial photoelectric conversion efficiency, improve open circuit voltage and light stability, and improve the effect of light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

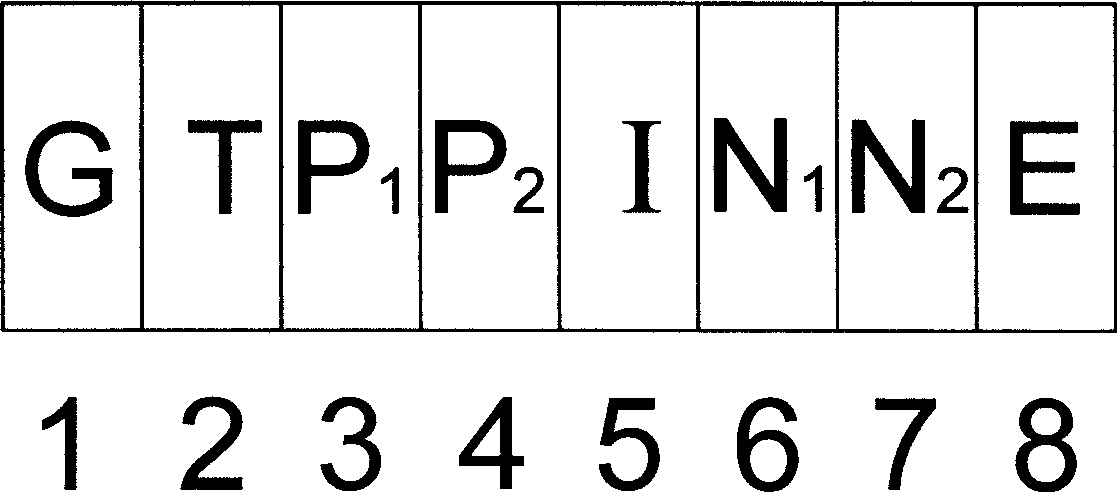

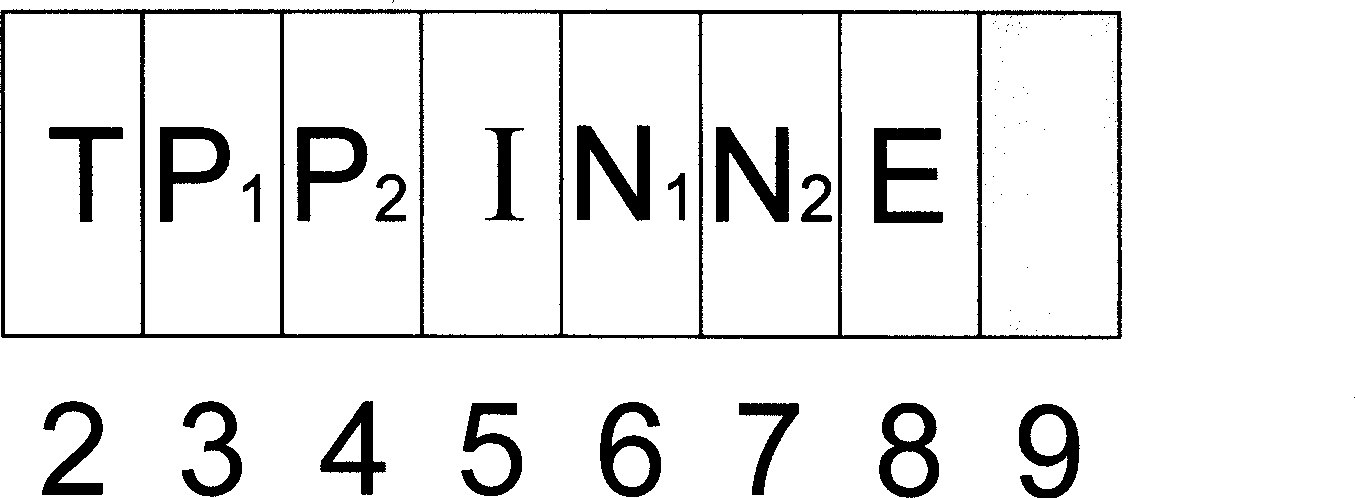

[0023] refer to figure 2 , image 3 . In the single-junction doped layer silicon-based thin film solar cell embodiment, figure 2 The p-i-n structure silicon-based thin film solar cell shown is fabricated on a transparent substrate, image 3 The shown n-i-p type silicon-based thin film solar cell is fabricated on an opaque substrate.

[0024] When the p-i-n type structure is adopted, the SnO with textured structure using transparent conductive glass as the transparent substrate 1 2 :F on the transparent conductive film 2, first deposit a boron-doped p-type silicon-doped layer 3 with a thickness of 15.0-25.0nm, the specific material is p-type boron-doped microcrystalline silicon, and the deposition of this layer adopts PECVD technology, basically The deposition condition is 13.56~100MHz high-frequency glow excitation, grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com