III-nitride substrate growing method, substrate and LED (light emitting diode)

A growth method and nitride technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of complex growth process, graphene wrinkles, introduction of impurities, etc., and achieve the effect of simple growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

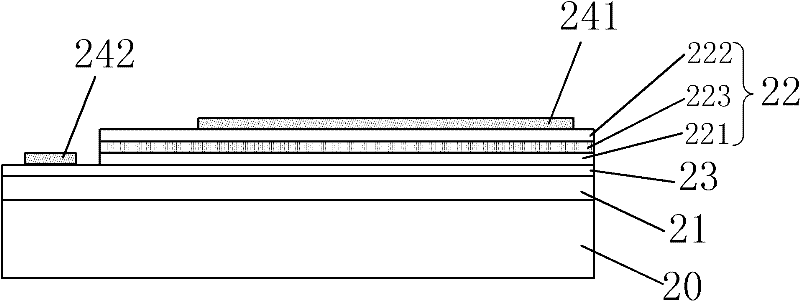

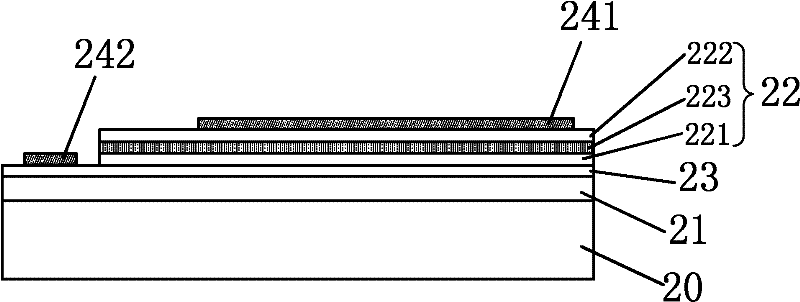

[0018] A method for growing a III-nitride substrate provided by the present invention and specific implementations of the substrate will be described in detail below with reference to the accompanying drawings.

[0019] The following uses the MOCVD process to grow GaN as an example for illustration. For materials such as AlN, InN and InGaN, except for a slight difference in the specific parameters of the growth process, the others are roughly the same as the following embodiments.

[0020] Preparation of graphene: chemical vapor deposition or graphite redox method can be used, preferably chemical vapor deposition. The specific implementation of the chemical vapor deposition method belongs to the known technology and will not be described in detail here.

[0021] Transfer of graphene: Spin-coat polydimethylsiloxane (PDMS) layer on graphene film, because PDMS has certain stickiness, can adhere to graphene film layer, and utilize chemical method to corrode graphene substrate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com