Metal welding rapid formation system and method based on CMT

A metal welding and fast technology, applied in welding equipment, metal processing equipment, arc welding equipment, etc., can solve the problems of insufficient depth of metal welding, large heat input, low precision and reliability, and achieve the effect of ensuring precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In order to make the advantages, technical solutions and objectives of the present invention clearer, the embodiments of the present invention will be fully and clearly described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present application, not all of them.

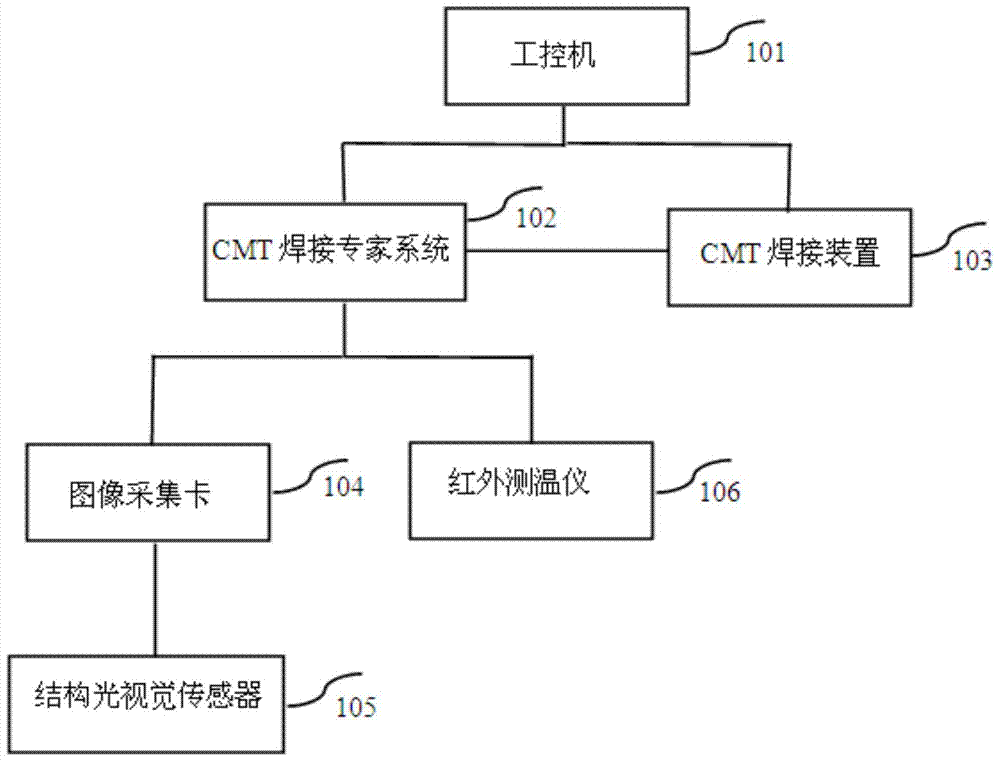

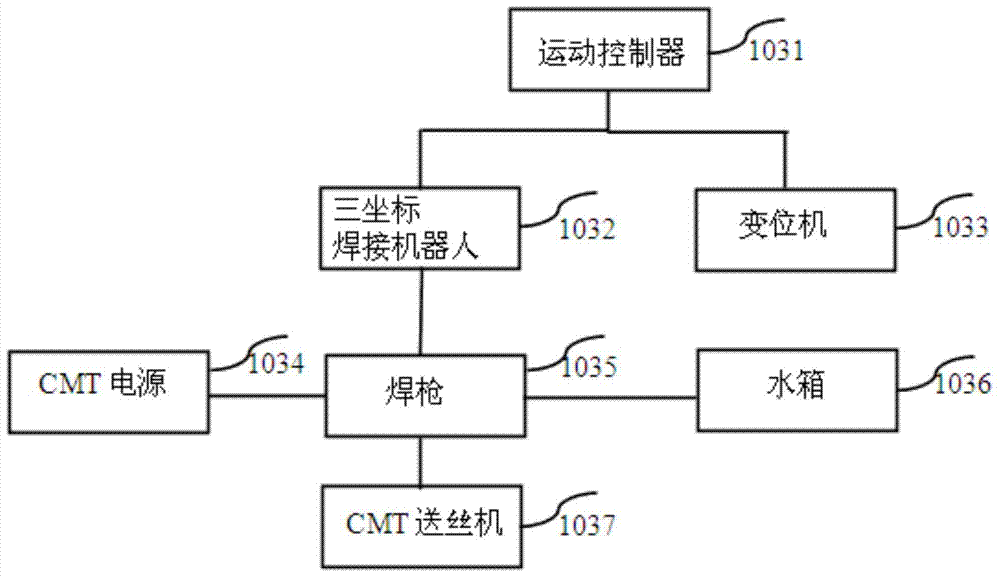

[0037] see figure 1 As shown, the present invention provides a metal welding rapid prototyping system based on CMT, including: industrial computer 101, CMT welding expert system 102, CMT welding device 103, image acquisition card 104, structured light vision sensor 105 and infrared thermometer 106.

[0038] The industrial computer 101 is used to process data according to the layered slicing of the 3D CAD model of the target formed part, generate path code information for welding forming and serve as the hardware basis of the CMT welding expert system 102 .

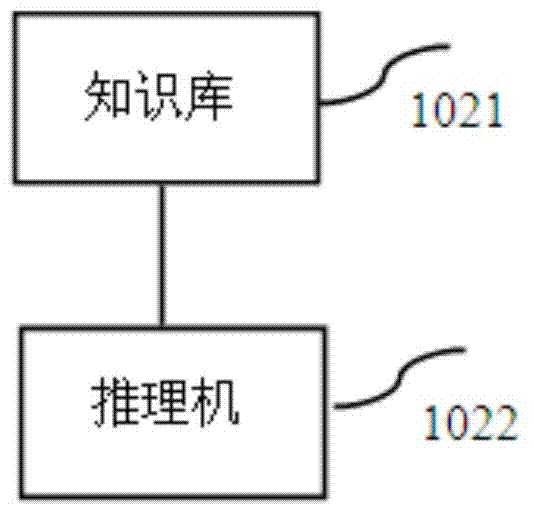

[0039] The CMT welding expert system 102 is used to generate the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com