Piezoelectric driving type low-temperature in-situ high-frequency reciprocating fretting friction and wear test platform

A low-temperature in-situ, fretting friction technology, applied in the direction of testing wear resistance, etc., can solve the problems of inability to monitor the microstructure and morphology, and achieve the effect of compact structure, wide application and small structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

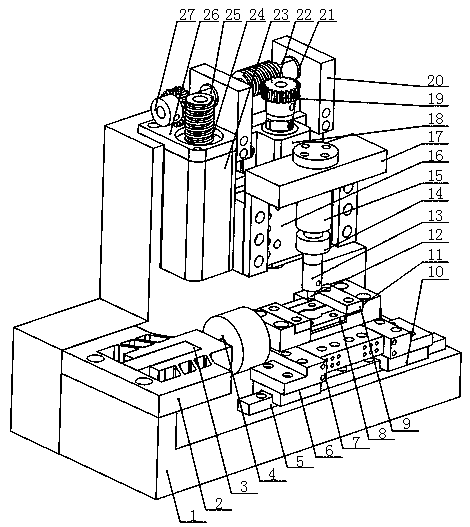

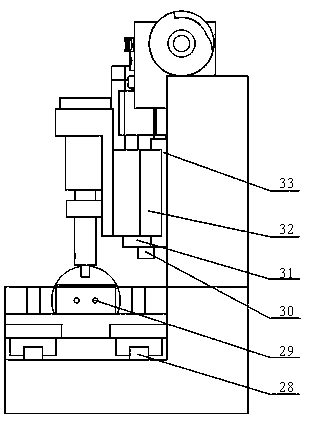

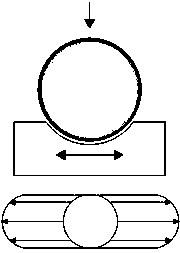

[0035] See Figure 1 to Figure 4 As shown, the in-situ high-frequency reciprocating fretting friction and wear test platform under the scanning electron microscope based on the piezoelectric drive mode designed in the present invention consists of a test pressure loading unit, a high-frequency reciprocating drive unit, a low-temperature precision clamping unit and a data acquisition unit It consists of four major parts. Among them, the test pressure loading unit is powered by a precision servo motor, through a two-stage worm gear reduction mechanism and a screw nut pair to complete precise pressure loading; the high-frequency reciprocating unit is arranged on the lower side, using advanced piezoelectric ceramic drive technology, and independent design The flexible hinge outputs high-frequency micro-motion displacement; the low-temperature precision clamping unit is precisely clamped by the upper and lower clamps, and low-temperature loading is achieved through the liquid nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com