Variable-range in-situ hardness test device under prestress

A technology of hardness testing and variable range, applied in the direction of measuring device, testing material hardness, strength characteristics, etc., to achieve the effect of high space utilization, compact space layout and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

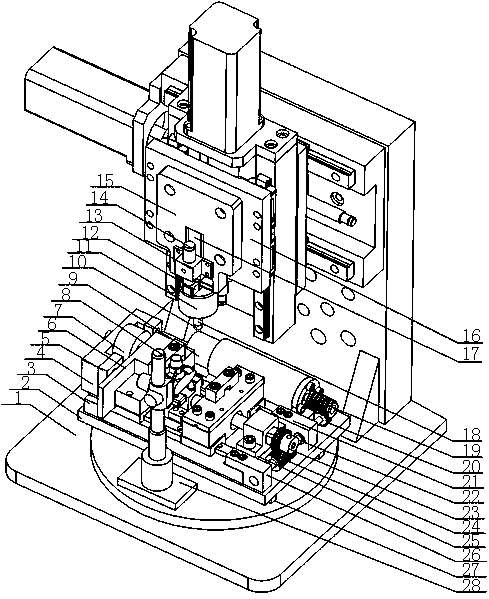

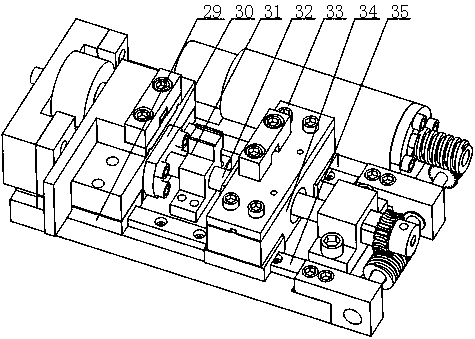

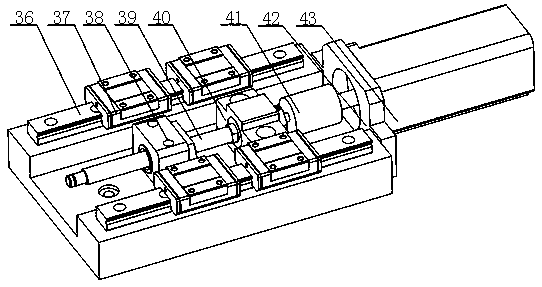

[0024] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1 to Figure 3 As shown, the in-situ hardness testing device with variable range under prestress of the present invention is composed of four major parts: X / Z axis degree of freedom precision motion unit, variable range press-in unit, test prestress loading unit and data acquisition unit. Among them, the X / Z-axis degree of freedom precision motion unit is composed of the vertical rigid combination of the X-direction mobile platform and the Z-direction mobile platform. The individual parts are powered by precision servo motors, which are converted into linear motion through ball screw nut pairs. Accurate positioning of the indenter space is realized; the variable-range press-in unit is arranged on the upper side, the Z-degree-of-freedom platform realizes large-scale loading, and the advanced piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com