One-step molding device for double-layer thick plastic sheet and molding process thereof

A technology of plastic sheet and forming equipment, which is applied in the field of making double-layer thick plastic sheets hollow, heat-sealed and formed at one time, and in the field of blistering, which can solve the problem of limiting the application of double-layer blister products, increasing the cost of blister products, and low production efficiency and other problems, to achieve the effect of small equipment occupation, low manufacturing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

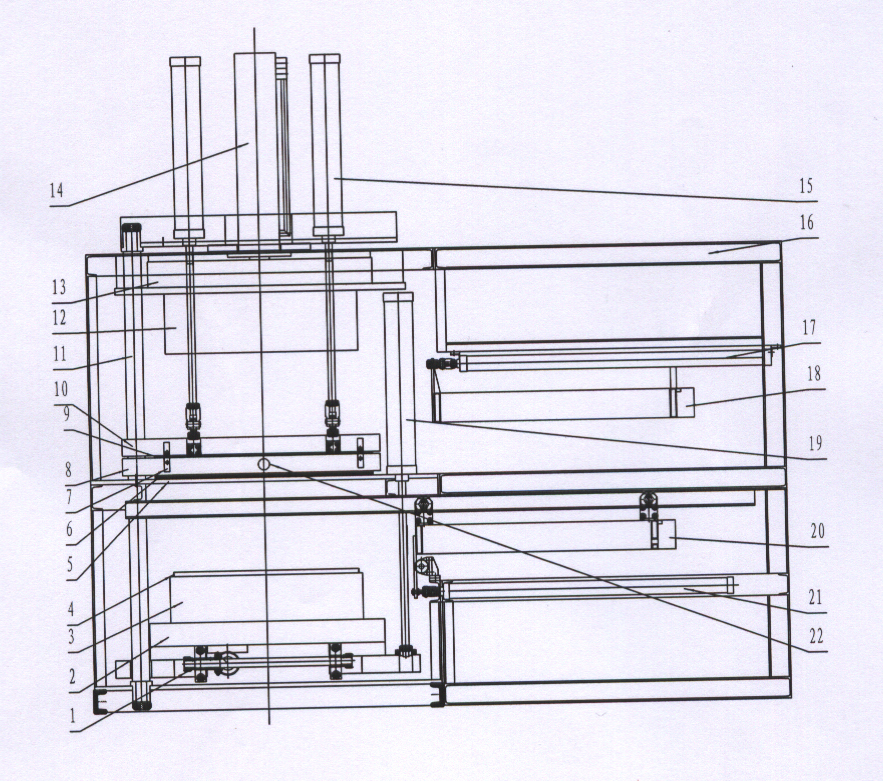

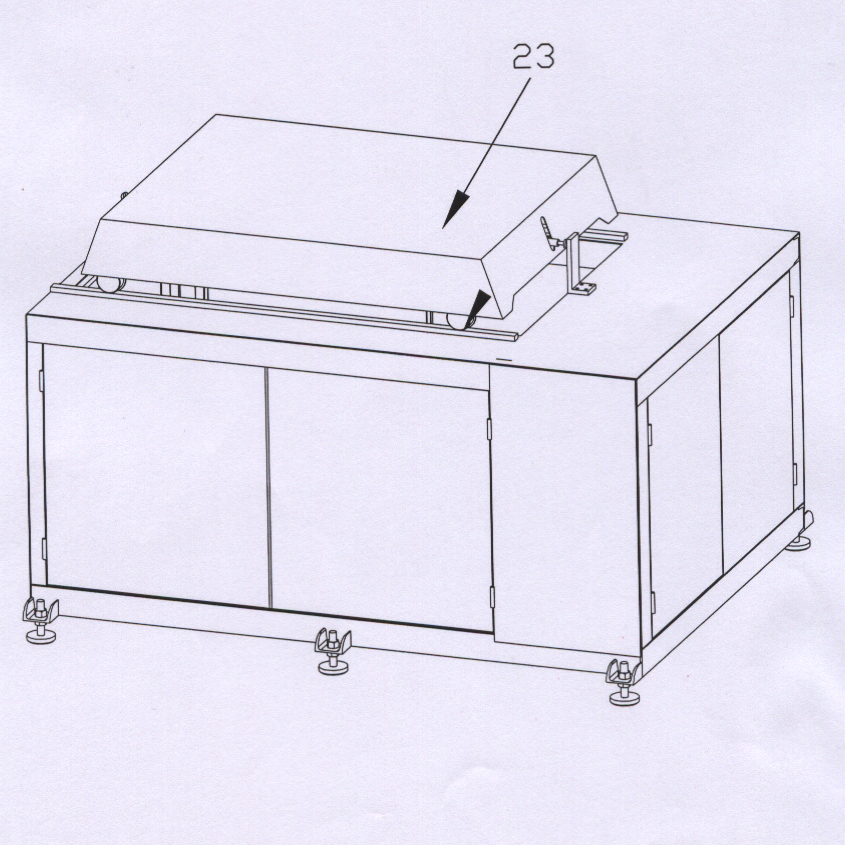

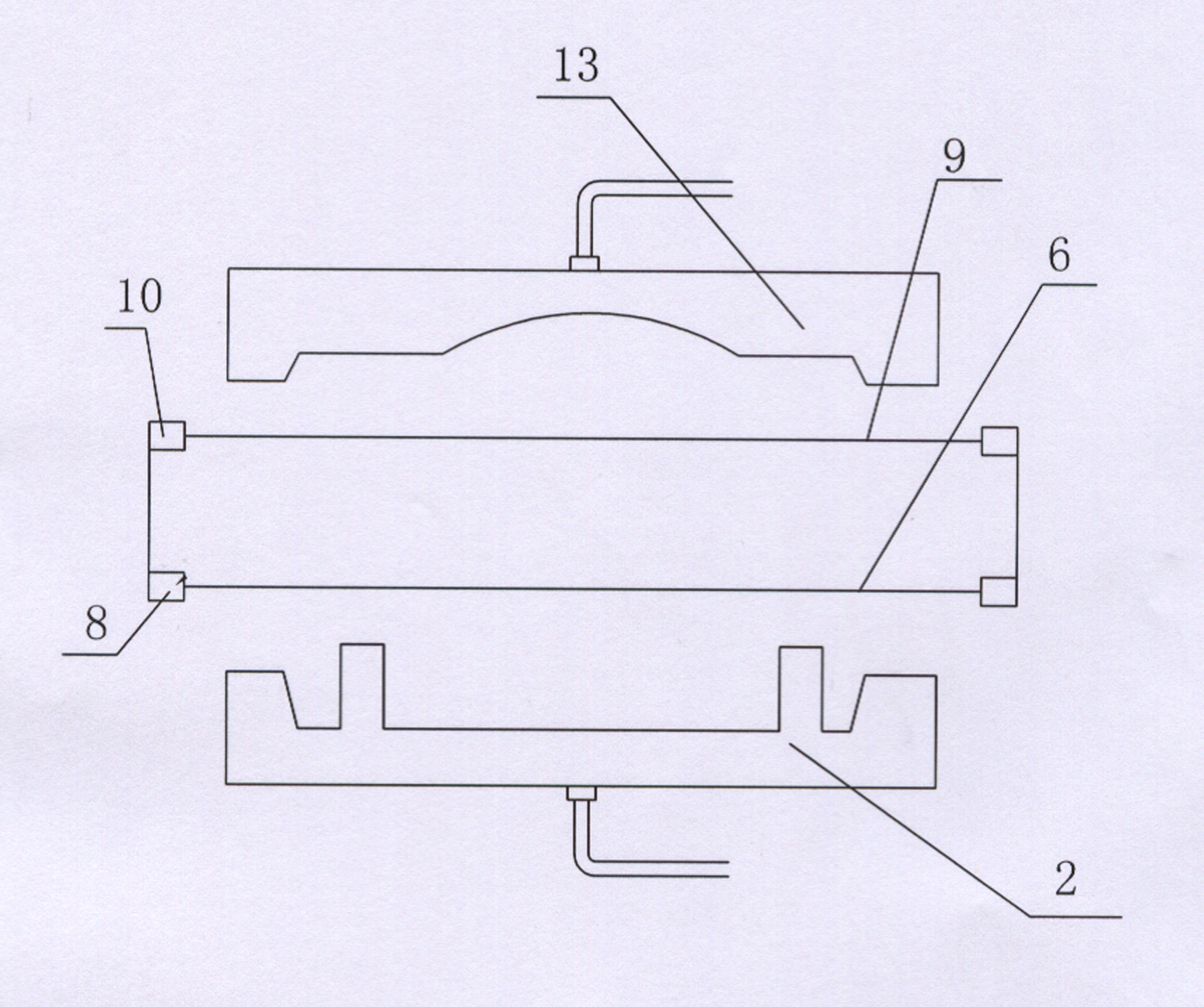

[0016] Accompanying drawing has represented the structure of the present invention and its embodiment, further illustrate the relevant details and working principle of its embodiment below again in conjunction with accompanying drawing. Double-layer thick sheet plastic sheet once hollow, plastic-absorbing, heat-synthesizing equipment, such as figure 1 As shown, it is mainly composed of the lower mold lifting synchronous gear rack 1, the lower mold base 2, the lower mold and the lower mold vacuum box 3, the edge trimming device, the lower template 5, the lower plastic plate 6, the pressure frame connector 7, and the lower pressure frame 8. Upper plastic plate 9, upper press frame 10, guide post 11, upper mold and upper mold vacuum box 12, upper mold base 13, upper mold oil cylinder 14, press frame cylinder 15, body 16, upper electric furnace cylinder 17, upper electric furnace 18. The lower mold holder cylinder 19, the lower electric furnace 20, the lower electric furnace cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com