Device for testing thermal friction coefficient of sheet material in hot stamping forming process

A technology of hot stamping and thermal friction, which is used in measurement devices, mechanical devices, analysis of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiments, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited thereto.

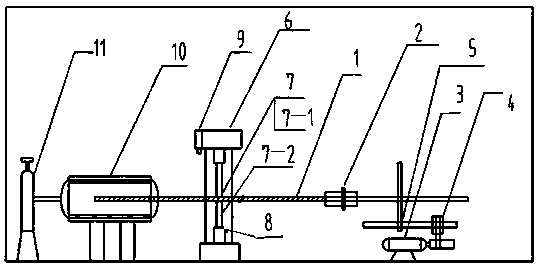

[0022] A device for testing the friction coefficient of a plate during hot stamping forming, including a heating furnace 10, an argon gas bottle 11, an infrared thermometer 9, a pressurizing device, and a drawing device, characterized in that: the heating furnace 10 is connected to the argon gas bottle 11 through a pipeline ; The pressurizing device is installed at the mouth of the heating furnace 10;

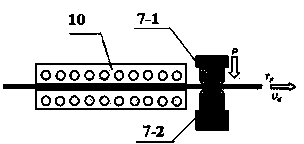

[0023] Described pressurizing device is made up of hydraulically driven indenter 7 and pressure sensor 8; Wherein indenter 7 is divided into upper indenter 7-1 and lower indenter 7-2, and they are placed perpendicular to horizontal direction respectively; Upper indenter 7 -1 is provided with a threaded rotating device, which is used to adjust the size of the gap, and can be freely ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com