Electroplating production line system with rapid pre-cleaning and drying functions

An electroplating production line and functional technology, applied in drying, drying machine, plating tank and other directions, can solve the problems of shortening the electroplating production line time, lack of surface cleaning mechanism, reducing the quality of workpiece electroplating, etc., to shorten the overall working hours, save manpower, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

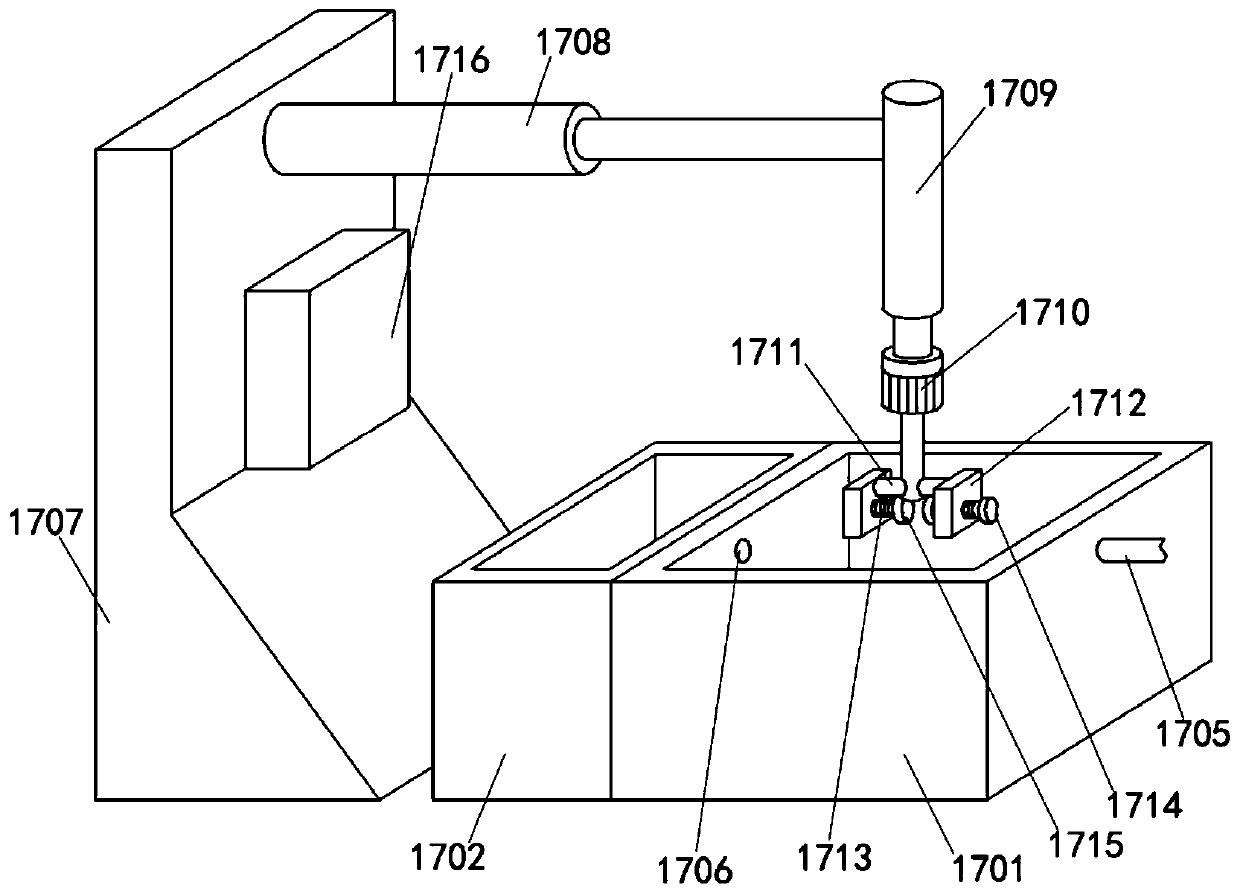

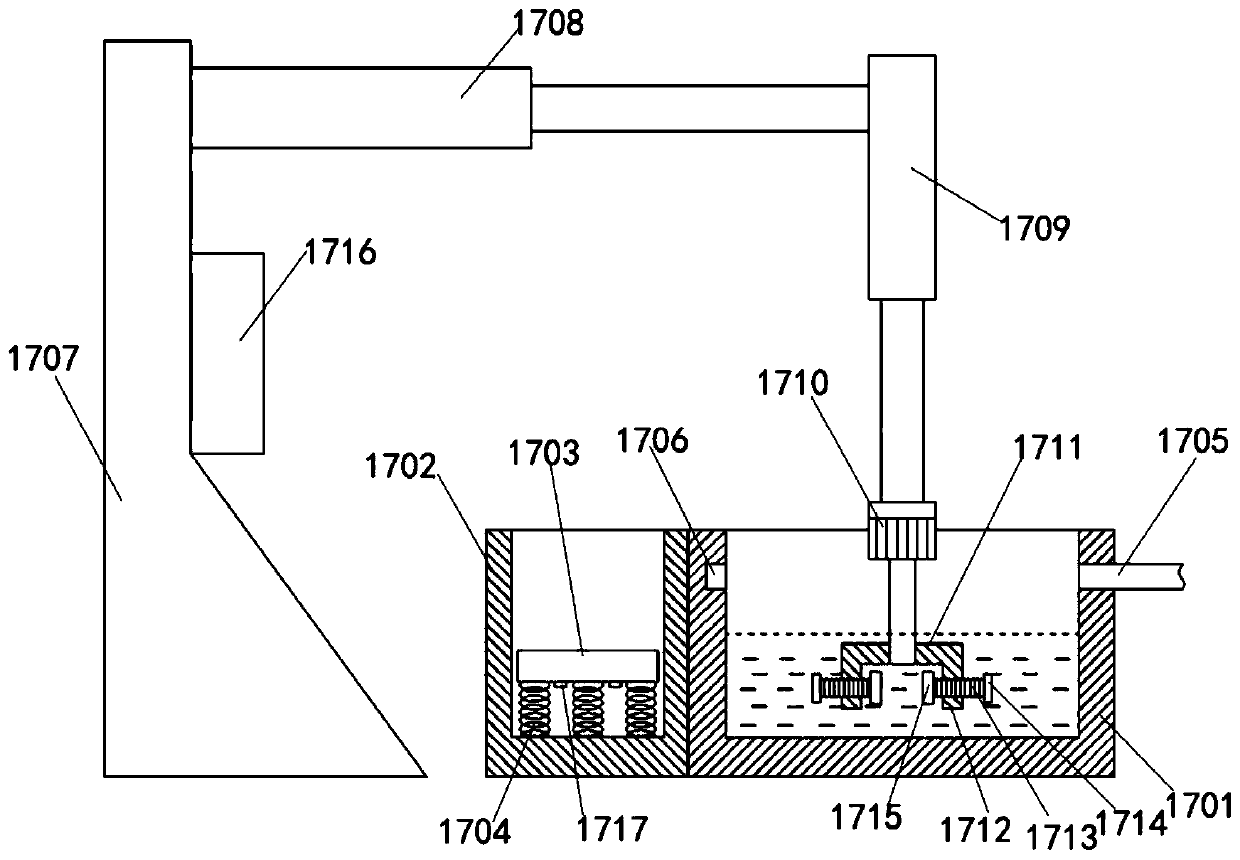

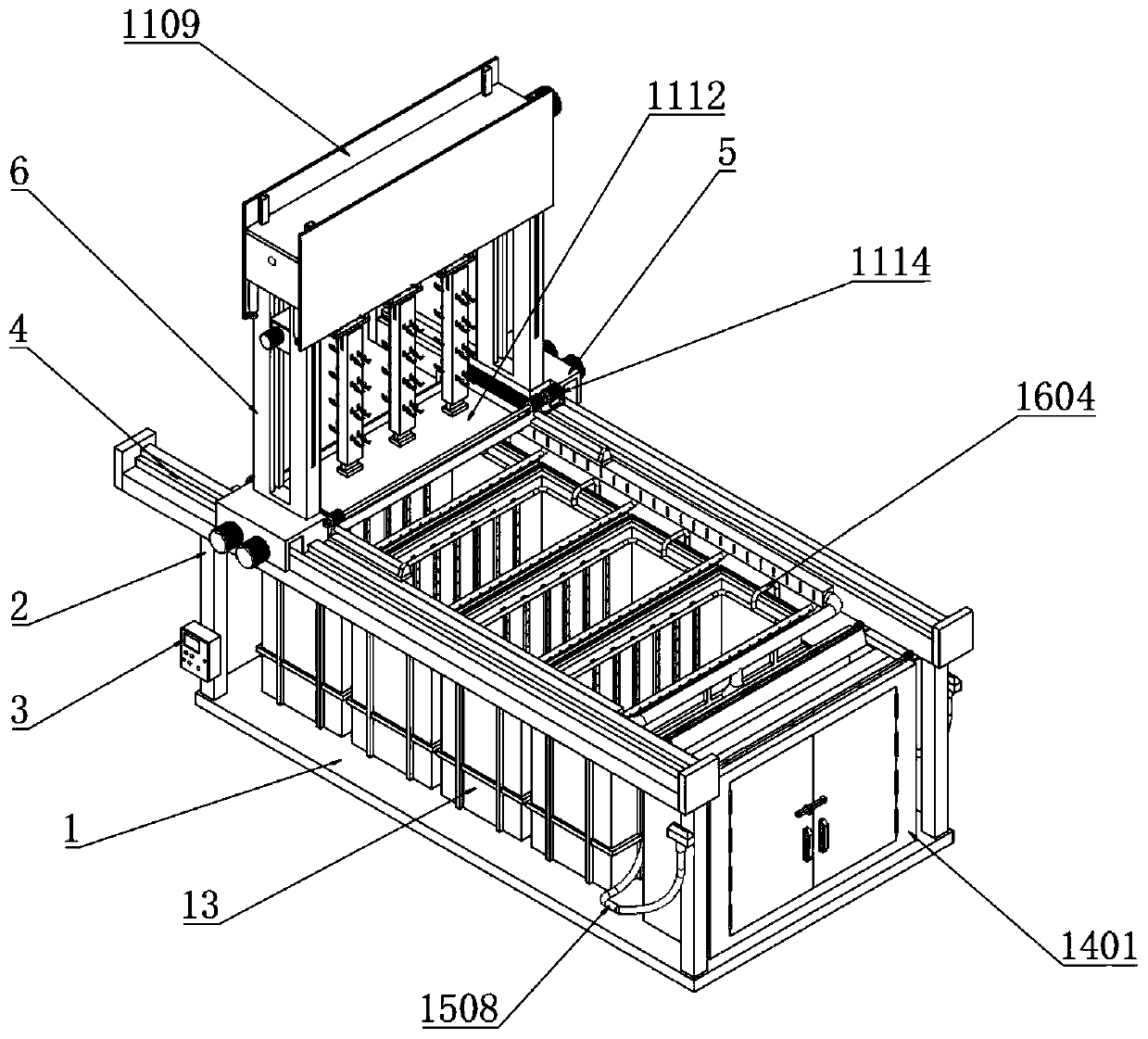

[0038] Example: such as Figure 1-9 An electroplating production line system with rapid pre-cleaning and drying function is shown, including a pre-cleaning and drying device and an electroplating device. After the workpiece is cleaned and dried by the pre-cleaning and drying device, the operator hangs it on the electroplating Plating is carried out on the hook 1216 of the device. The pre-cleaning and drying device includes a cleaning box 1701 filled with cleaning liquid. The side wall of the cleaning box 1701 is fixedly connected with a receiving box 1702, and a buffer plate 1703 is built in the receiving box 1702. The buffer plate 1703 is connected with a plurality of springs 1704. The bottom wall of the receiving box 1702 is fixed, one side wall of the cleaning box 1701 communicates with the hot air pipe 1705, and an infrared temperature detector 1706 is embedded on the other side wall. It also includes a support 1707 fixed to the ground, the side wall of the support 1707 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com