Preparation method of diamond bits and sintering device thereof

A diamond drill bit, hot pressing sintering technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of prolonged production cycle, uneven density, fixed and unadjustable frequency, etc., to improve production efficiency and service life, guarantee The consistency of product quality and the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

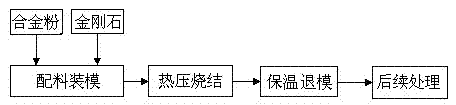

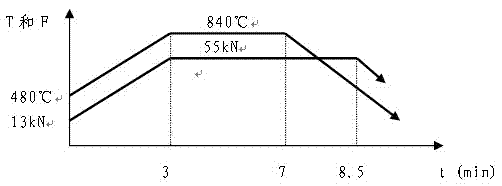

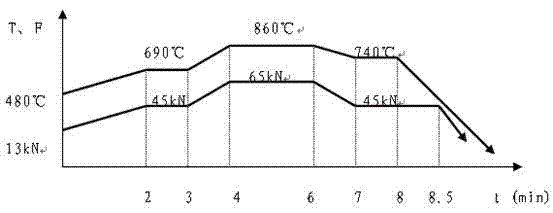

[0036] see figure 1, a method for preparing a diamond drill bit, comprising batching and loading into a mold, hot pressing and sintering, heat preservation and demoulding, and subsequent processing steps. The batching and molding process is to mix the pre-prepared alloy powder and diamond uniformly at a ratio of 1:10 to 15 to obtain metal powder, and fill it into a graphite mold. The ratio of this embodiment is 1:12. The hot pressing sintering process adopts variable intermediate frequency sintering, two-way vibration pressure and double-track temperature and pressure curve control technology. The graphite mold placed in the variable intermediate frequency induction coil is subjected to two-way vibration hot pressing sintering. The sintering temperature is 400-950 °C and the pressure is 10~70KN, the vibration frequency of the indenter is 700~1000 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com