Device for high-frequency induction cladding with assistance with ultrasonic vibration and working method for device

A high-frequency induction and ultrasonic vibration technology, which is applied in the coating process and coating of metal materials, can solve problems such as residual stress, cladding layer bubbles, and poor surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

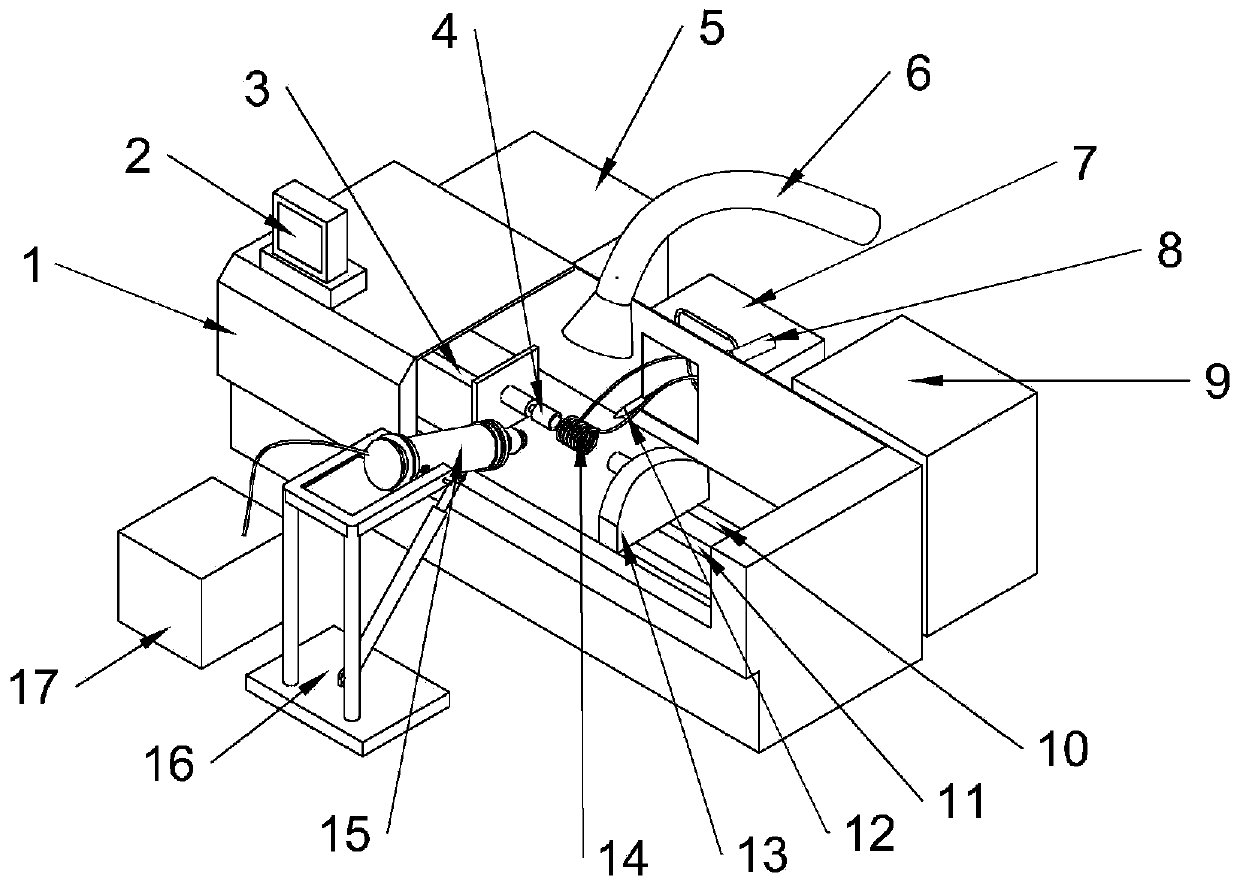

[0025] Below in conjunction with accompanying drawing this patent is further described:

[0026] Such as figure 1 As shown, this patent is a device and working method for ultrasonic vibration-assisted high-frequency induction cladding, including: 1. Horizontal machine tool 2. PLC controller 3. Slider box 4. Triangular chuck 5. Power controller 6 .Smoke removal system 7. Induction power supply 8. Infrared thermometer 9. Industrial water cooling circulation system 10. Guide rail 11. Ball screw 12. Nozzle 13. Thimble 14. Induction coil 15. Horn 16. Bracket 17. Ultrasonic generation device. The PLC controller 2 is connected with the power controller 5 and the infrared thermometer 8, a motor is arranged in the slide box 3 and the output shaft of the motor is connected with the triangular chuck 4, and the power controller 5 is connected with the sensor The power supply 7 is connected, the pipe of the smoke removal system 6 is fixed on the roof, the induction power supply 7 is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com