Aluminum aerosol can and aluminum bottle and method of manufacture from coil feedstock

一种铝罐、铝合金的技术,应用在气溶胶罐领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

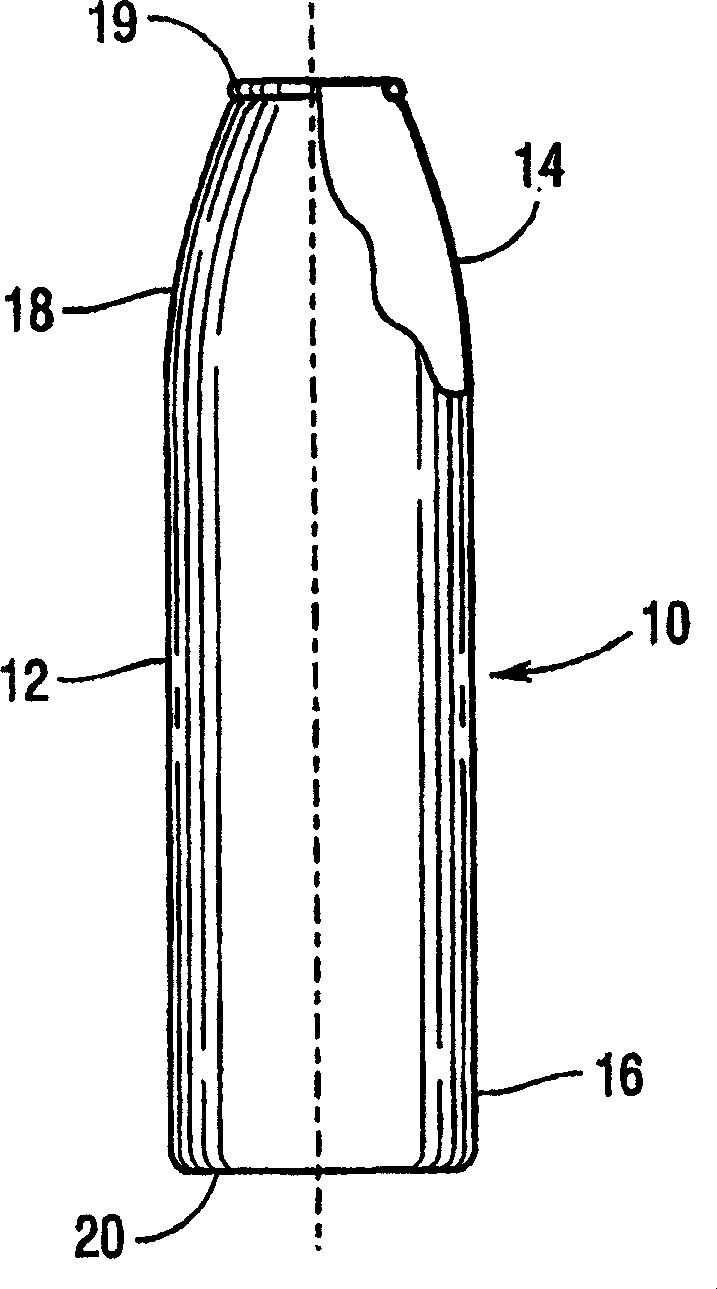

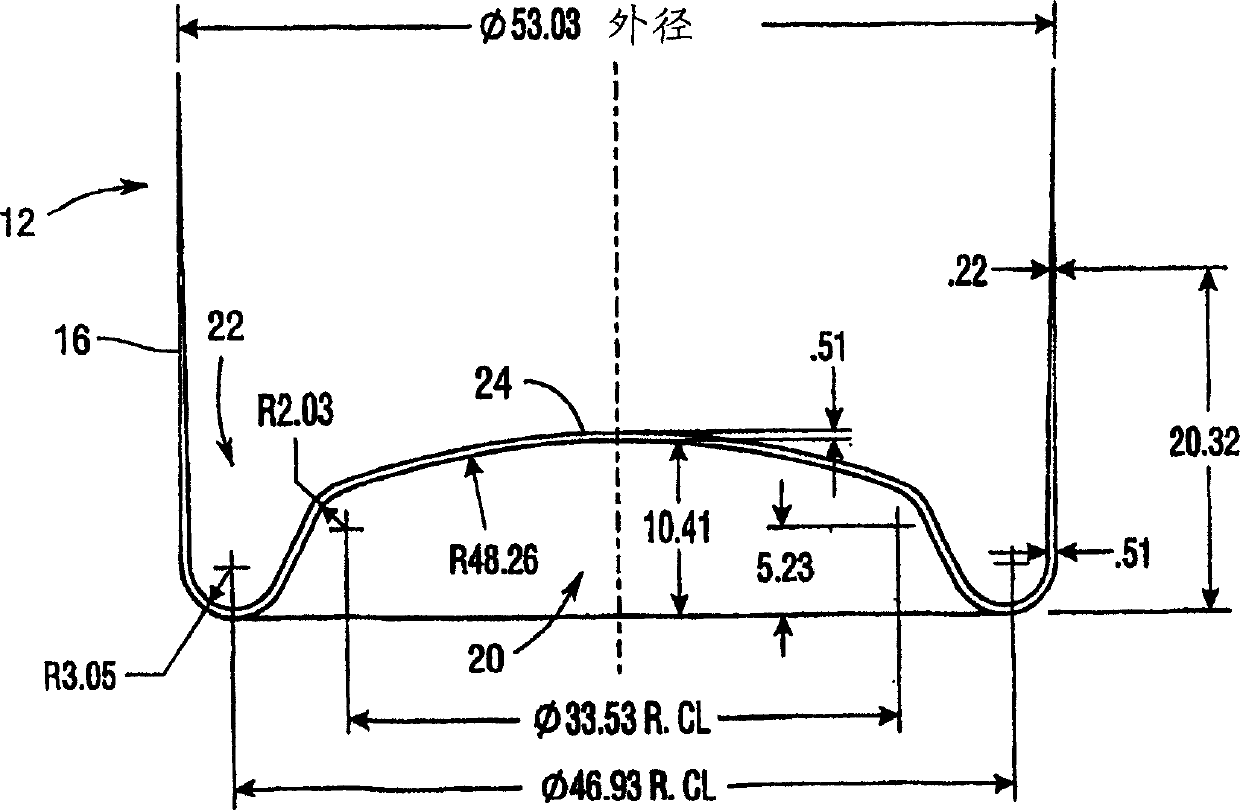

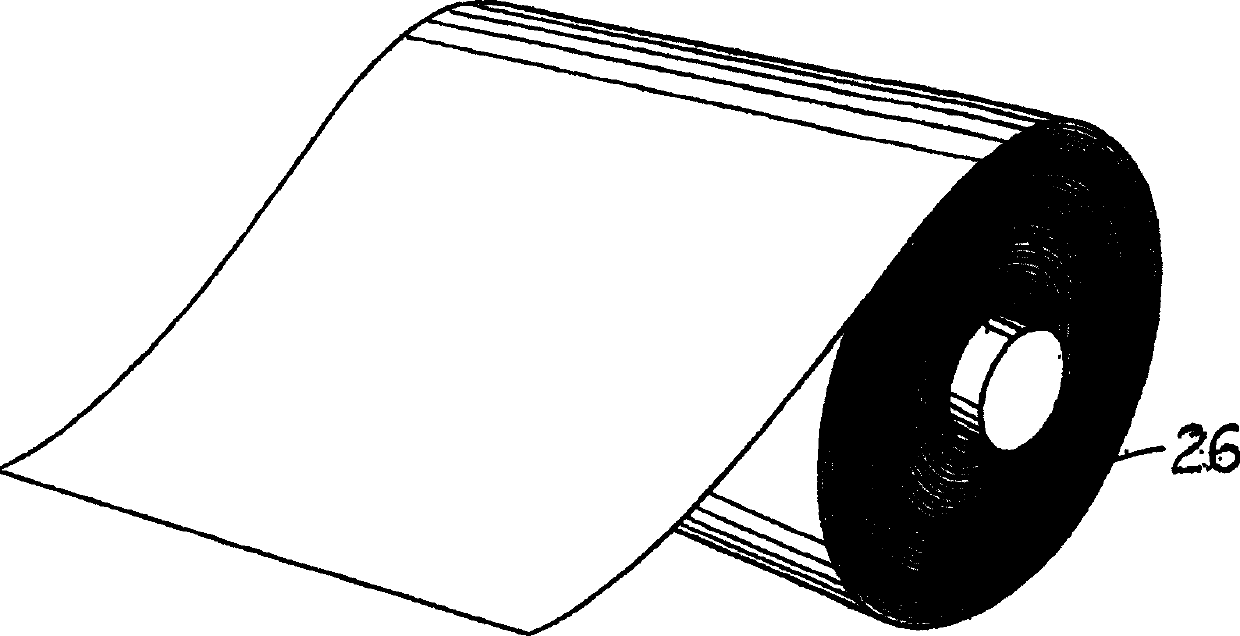

[0036] For ease of description and illustration, the present invention primarily describes the fabrication and necking of aluminum aerosol cans that have been drawn and attenuated, but it should be understood that the application is not limited to such cans. The present invention can also be applied to the method of necking processing other kinds of aluminum materials, aluminum bottles, metal containers and profiles. It should also be understood that, for convenience, the term "aerosol can" is used throughout this application to include not only cans, but also aerosol bottles, aerosol containers, non-aerosol bottles, and non-aerosol containers.

[0037] The present invention relates to an aerosol can, and a method of manufacturing an aluminum alloy can, the performance of the aluminum alloy can is the same as or better than that of the conventional aluminum alloy can, and the aluminum alloy can is allowed to be carried out on it Produce high-quality printing and designs, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com