Rework method for back-side metal process

A backside metal and backside technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of product scrapping, loss, abnormality, etc., and achieve the effect of ensuring yield and reliability, consistent appearance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

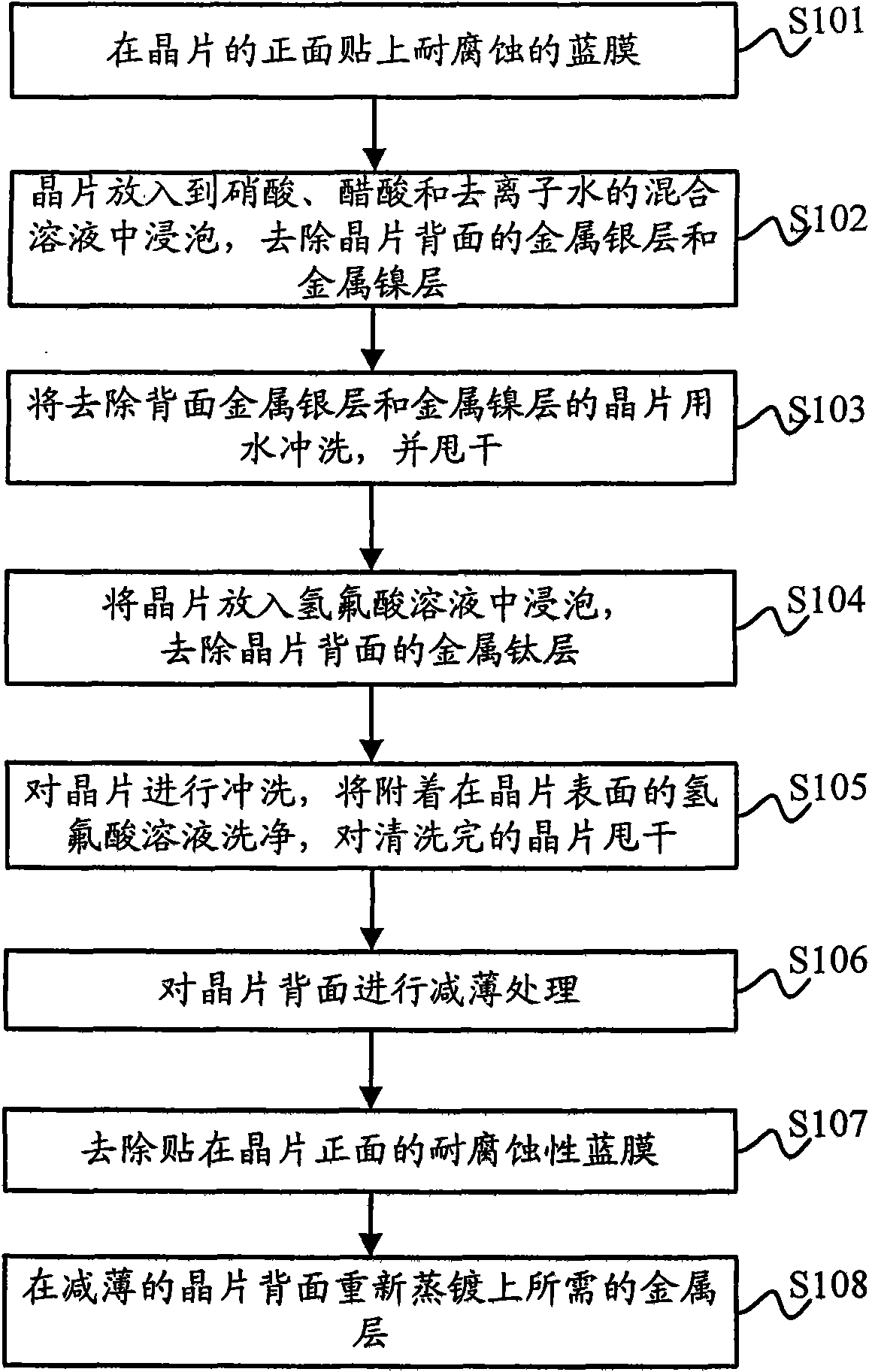

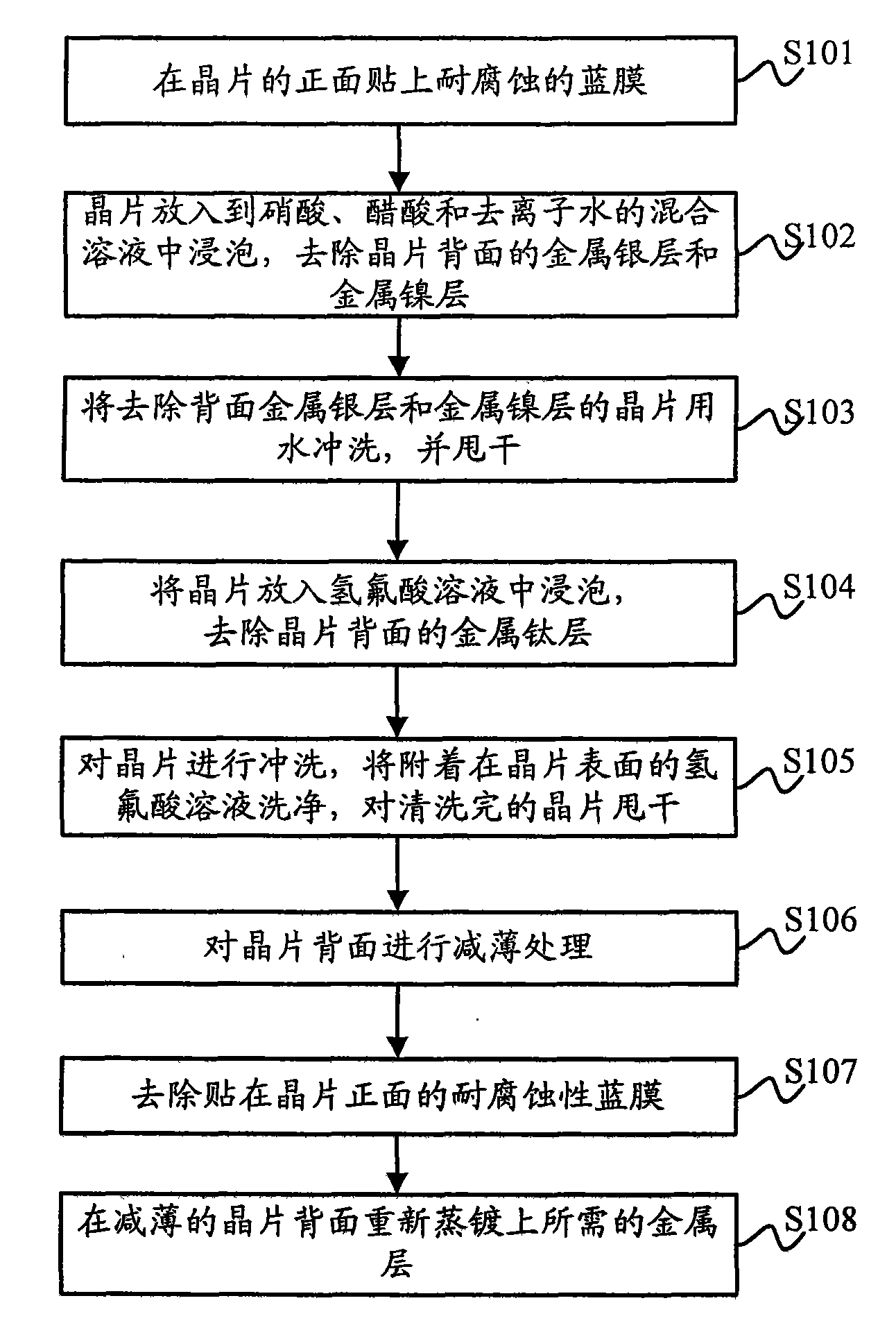

[0029] In the method for reworking the backside metal process provided by the embodiment of the present invention, the backside metal of the abnormal wafer is removed by wet etching, and the backside of the wafer from which the backside metal is removed is thinned again, and then evaporated on the backside of the wafer The required metal layer is plated. After the above process, the product that has an abnormal back metal layer can be reworked, and the requirements of normal products can be met.

[0030] A specific embodiment of the method for reworking the backside metal process provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0031] In the embodiment of the present invention, in particular, a relatively common rework process of a wafer whose back metal layers are sequentially titanium (Ti), nickel (Ni) and silver (Ag) is taken as an example for illustration. However, the method for reworking the backside metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com