Preparation method of metal chalcogen compound thin film

A technology of compound and metal sulfur, which is applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of easy cracking of the film, difficult control of film composition and thickness, etc., and achieve the effect of ensuring the shape and thickness, solving the problem of easy expansion, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

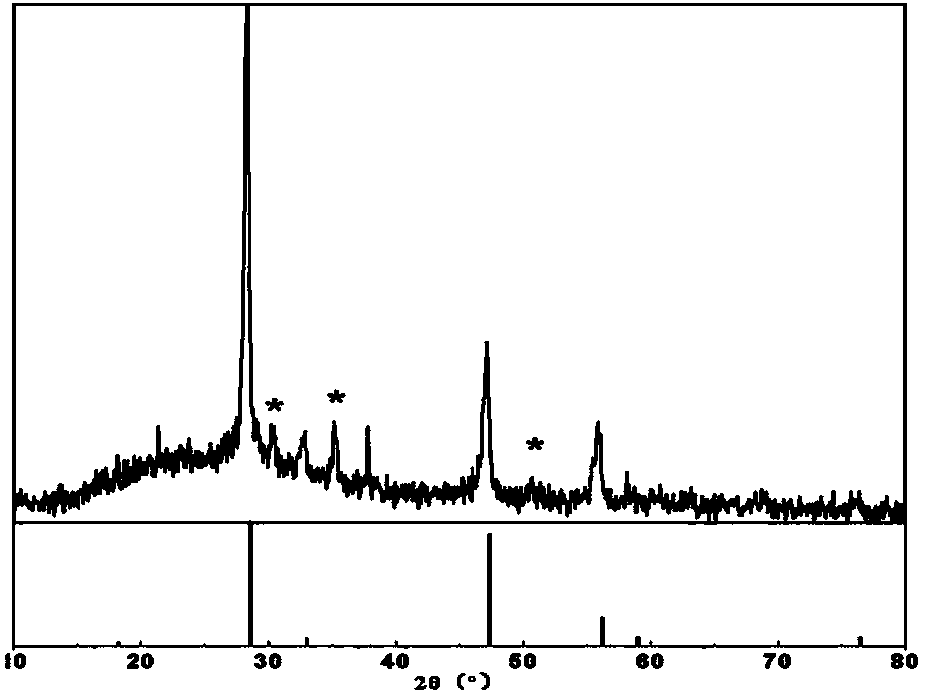

[0037] This embodiment illustrates the preparation method of a kind of metal chalcogen compound film provided by the present invention, adopts this method to prepare ferrous disulfide (chemical formula FeS 2 ) compound film.

[0038] A. The conductive substrate is used as a working electrode in the electrolyte solution, and the required single-component metal or alloy gold film is prepared by electrodeposition, and then the substrate is cleaned with deionized water;

[0039] A titanium sheet of 20×20×0.2 mm was selected as the conductive substrate, cleaned with degreasing agent, high-temperature lye, ethanol and deionized water, and then dried for later use.

[0040] Use constant potential deposition, use graphite electrode as counter electrode, saturated calomel electrode as reference electrode, electrolyte formula is 9.50mol / L FeSO 4 Main salt, 8.5mol / L NaCl supporting electrolyte, 10.0mol / L KSCN complexing agent, solution pH=3.0, deposition potential is -6.0V vs. SCE, elec...

Embodiment 2

[0047] This embodiment illustrates the preparation method of a kind of metal chalcogen compound film provided by the present invention, adopts this method to prepare ferrous disulfide (chemical formula FeS 2 ) compound film.

[0048] A. The conductive substrate is used as a working electrode in the electrolyte solution, and the required single-component metal or alloy gold film is prepared by electrodeposition, and then the substrate is cleaned with deionized water;

[0049] Select a 20×20×0.2mm stainless steel sheet as the conductive substrate, wash it with degreasing agent, high temperature lye, ethanol and deionized water, and then dry it for later use.

[0050] Using constant potential deposition, graphite electrode is used as the counter electrode, saturated calomel electrode is used as the reference electrode, and the electrolyte formula is 0.001mol / L FeSO 4 Main salt, 0.001mol / L NaCl supporting electrolyte, 0.001mol / L KSCN complexing agent, solution pH=1, deposition po...

Embodiment 3

[0057] This embodiment illustrates the preparation method of a kind of metal chalcogen compound film provided by the present invention, adopts this method to prepare copper indium gallium selenide (chemical formula Cu(In,Ga)Se 2 ) compound film.

[0058] A. The conductive substrate is used as a working electrode in the electrolyte solution, and the required single-component metal or alloy film is prepared by electrodeposition, and then the substrate is cleaned with deionized water;

[0059] Select 35×25×5mm Mo conductive glass as the conductive substrate, wash it with degreasing agent, high temperature lye, ethanol and deionized water, and dry it for later use.

[0060] Using constant current deposition, using a Pt electrode as the counter electrode, the electrolyte formula contains 0.50mol / L InCl 3 , 0.05mol / L GaCl 2 , 0.002mol / L CuCl 2 and 0.006mol / L of SeO 2 aqueous solution, the supporting electrolyte is 0.1mol / L LiCl and 0.6mol / L NH 4 Cl, the complexing agent is 0.08...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com