Manufacturing technology of carbon fiber reflecting mirror

A preparation process and mirror technology are applied in the field of preparation technology of carbon fiber mirrors, which can solve the problems that carbon fiber mirrors are not suitable for large-diameter spherical mirrors, and the surface shape accuracy of carbon fiber mirrors is low. The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

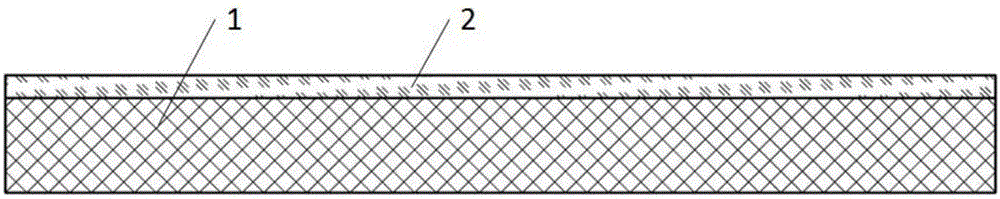

[0038] A preparation process of a carbon fiber reflector, comprising the preparation of a reflector substrate 3, the preparation of a reflector panel 4, bonding, detection, coating and polishing, the specific steps are as follows:

[0039] Step 1, preparation of mirror base 3

[0040] 1a) preparing a mirror base mold according to the carbon fiber mirror to be prepared;

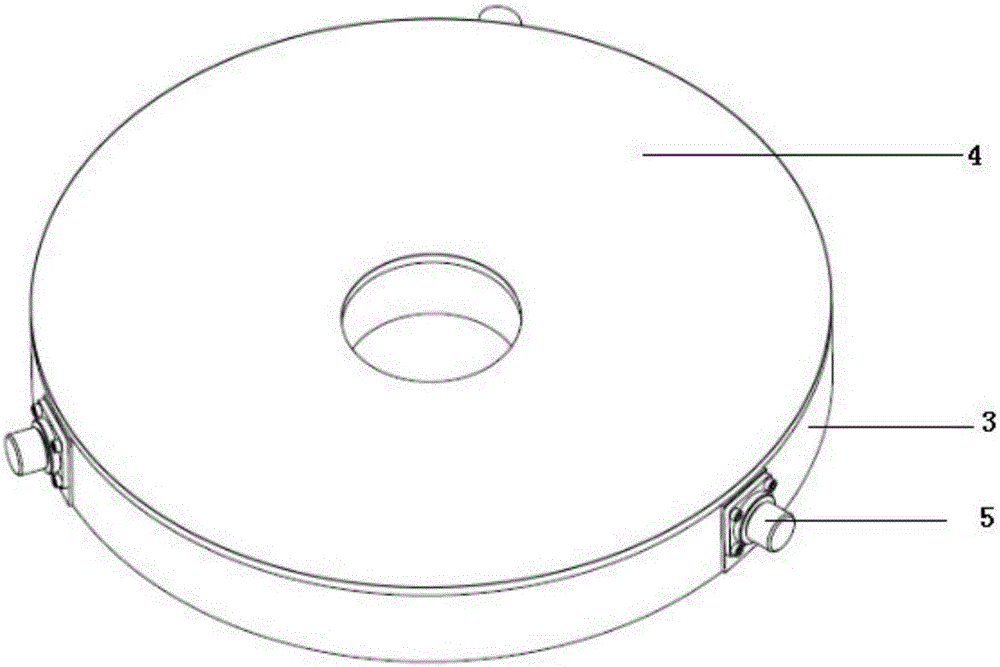

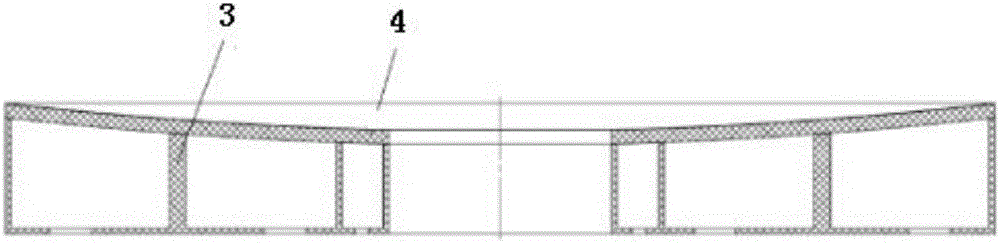

[0041] The above-mentioned preparation process is common sense for those skilled in the art, and there is no special requirement; generally, in order to ensure the accuracy of the mirror panel 4, the mirror base mold adopts high-precision processing; in order to make the prepared mirror base 3 lightweight, the mirror base mold is preferably Using a mold with a triangular lightweight design, such as Figure 4 , this design is the prior art; the material of the reflector base mold is preferably Invar;

[0042] 1b) coating a release agent on the surface of the mirror base mold to obtain a release layer;

[004...

Embodiment 1

[0067] The parameters of the carbon fiber reflector to be designed are: diameter 350mm, spherical radius 1510.7mm, the quality of the reflector is required to be no more than 2Kg, and the surface shape accuracy is better than λ / 30 (λ=632.8nm); after optimized design, the carbon fiber reflector The diameter-to-thickness ratio of the mirror is 7.5:1, that is, the total thickness of the mirror is 47mm, the mirror base adopts a triangular lightweight design, the wall thickness and rib thickness are both 2mm, and the thickness of the mirror panel is 5mm. The preparation process of the reflector is as follows:

[0068] Step 1. First, use Invar as the material to prepare a triangular lightweight mirror base mold according to the carbon fiber mirror to be prepared, and then coat the release agent HD-9182 on the surface of the mirror base mold to obtain a release layer. Lay 168 layers of carbon fiber woven fabrics on the release layer (the carbon fiber woven fabrics are woven by M40JB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com