Method for manufacturing metallization groove holes in PCB

A technology of metallization groove and manufacturing method, which is applied in the direction of printed circuit manufacturing, electrical connection formation of printed components, electrical components, etc., can solve problems such as irregular shape of slot holes, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] This embodiment provides a method for manufacturing metallized slots in a PCB, and the specific manufacturing steps are as follows:

[0018] (1) Pressing to form a multi-layer board

[0019] Firstly, as in the production process of the PCB in the prior art, the raw materials of the PCB are cut to obtain a core board, and then the inner layer circuit is produced on the core board by using a negative film process. Through the AOI inspection of the inner layer, check whether there are defects such as open and short circuits, line gaps, and line pinholes in the inner layer lines, and products without defects enter the lamination process.

[0020] The first choice is to brown the core board, then stack the core board, prepreg and outer copper foil according to the design data, and then select the appropriate pressing conditions according to the Tg of the board to press the stacked boards into one. Form a multi-layer board.

[0021] (2) Milling slot hole

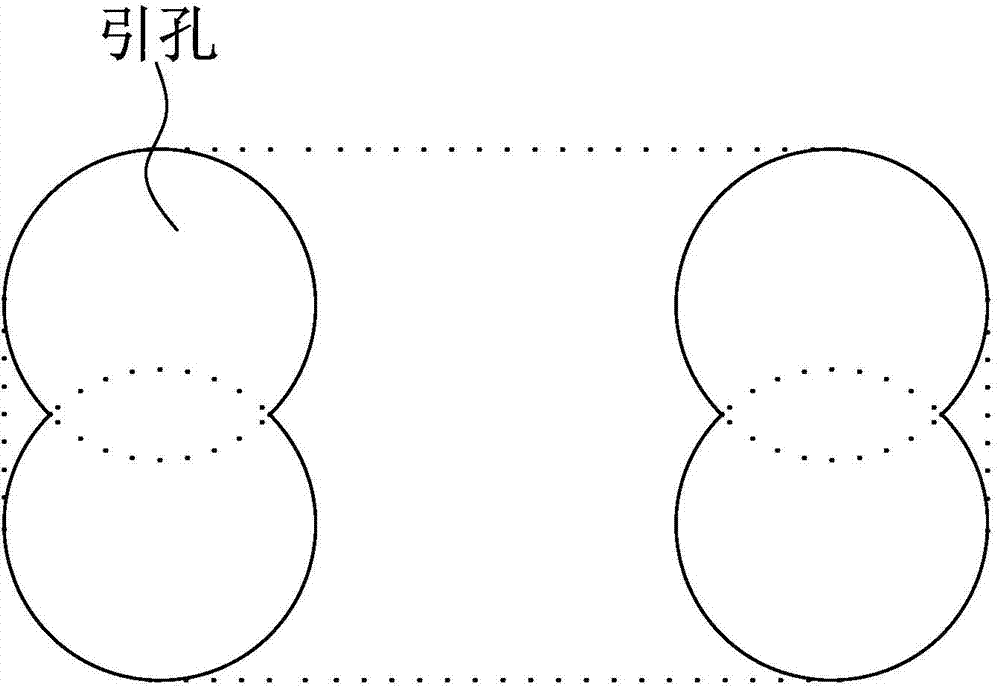

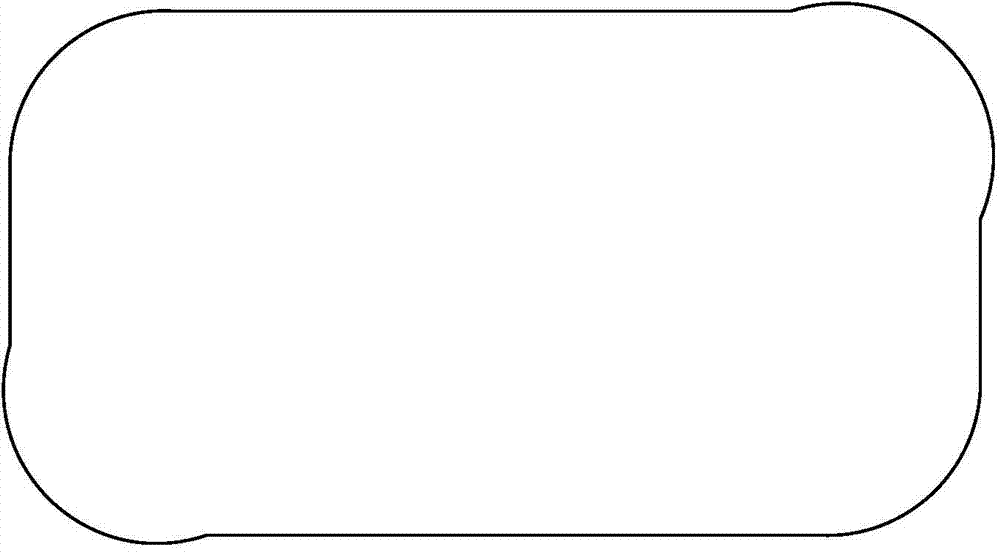

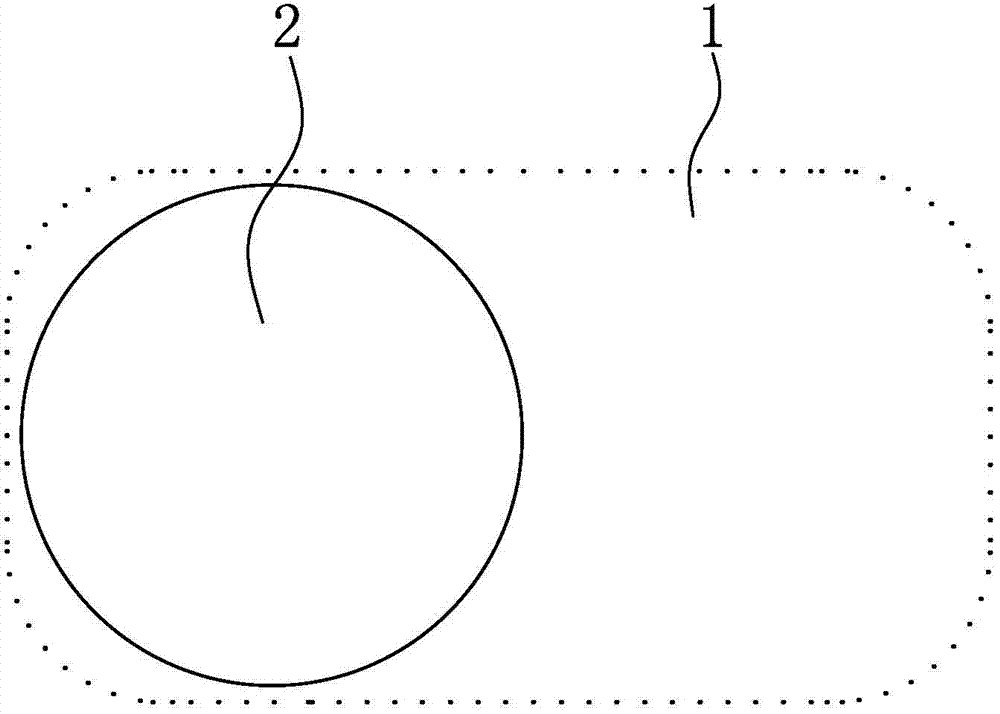

[0022] Drill a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com