Aluminum substrate layer material of copper-aluminum composite metal strip, strip and machining method thereof

A copper-aluminum composite board and copper-aluminum composite technology, which is applied in the field of material processing, can solve the problems of copper-aluminum composite row bonding strength and bending performance that cannot meet actual needs, and achieve improved machining performance, high material hardness, and suppression of abnormalities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

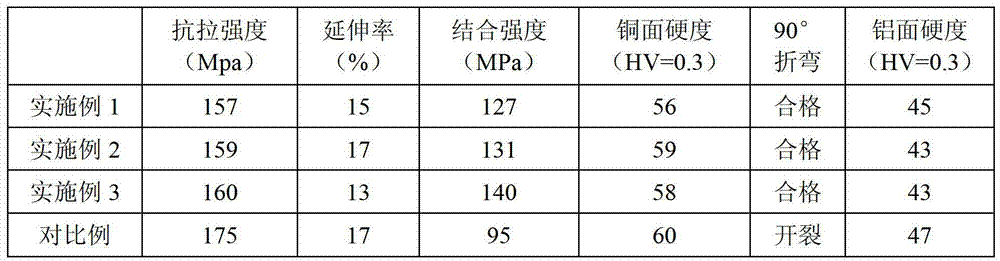

Examples

Embodiment 1

[0034] The aluminum matrix layer material of the copper-aluminum composite metal plate of this embodiment is composed of the following mass fractions: Si0.08%, Fe1.2%, Cu0.1%, Mn0.2%, Ti0.02 %, the balance is Al.

[0035] The copper-aluminum composite metal strip of this embodiment includes an aluminum base layer and a copper covering layer, the aluminum base layer is composed of the aluminum base layer material of this embodiment, the copper covering layer is composed of a copper covering layer material, and the grade of the copper covering layer material is TU2 , the state is TM. A copper cladding layer overlies the upper surface of the aluminum base layer.

[0036] The processing method of the copper-aluminum composite metal strip of the present embodiment comprises the following steps:

[0037] 1) Material preparation:

[0038] a) Measure the components of the aluminum matrix layer material according to the formula, first melt the aluminum ingot at 770 ° C, then add Si,...

Embodiment 2

[0050] The copper-aluminum composite metal strip material of this embodiment includes an aluminum matrix layer material and a copper covering layer material, and the aluminum matrix layer material is composed of the following mass fractions: Si0.04%, Fe0.5%, Cu0.4%, Mn2.0%, Ti0.03%, and the balance is Al.

[0051] The copper-aluminum composite metal strip of this embodiment includes an aluminum base layer and a copper covering layer, the aluminum base layer is composed of the aluminum base layer material of this embodiment, the copper covering layer is composed of a copper covering layer material, and the grade of the copper covering layer material is TU2 , the state is TM. A copper cladding layer overlies the lower surface of the aluminum base layer.

[0052] The processing method of the copper-aluminum composite metal strip of the present embodiment comprises the following steps:

[0053] 1) Material preparation:

[0054] a) Measure the components of the aluminum matrix l...

Embodiment 3

[0066] The copper-aluminum composite metal strip material of this embodiment includes an aluminum matrix layer material and a copper covering layer material, and the aluminum matrix layer material is composed of the following mass fractions: Si0.06%, Fe0.85%, Cu0.25%, Mn1.1%, Ti0.025%, and the balance is Al.

[0067] The copper-aluminum composite metal strip of this embodiment includes an aluminum base layer and a copper covering layer, the aluminum base layer is composed of the aluminum base layer material of this embodiment, the copper covering layer is composed of a copper covering layer material, and the grade of the copper covering layer material is TU2 , the state is TM. A copper cladding layer covers the upper and lower surfaces of the aluminum base layer.

[0068] The processing method of the copper-aluminum composite metal strip of the present embodiment comprises the following steps:

[0069] 1) Material preparation:

[0070] a) Measure the components of the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com