Method for measuring dielectric properties of diamond anvil cells in situ

A technology of diamond anvil and dielectric properties, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., and can solve problems such as measurement errors and incomplete insulation of sample chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Production of composite insulating gasket

[0027] Step 1: Choose T301 steel sheet as gasket material, and use diamond to pre-press the anvil to a thickness of about 40μm. There are diamond anvil surface indentation, diamond anvil chamfering indentation and diamond anvil side edge indentation on the steel sheet from the inside to the outside.

[0028]Step 2: Use a laser drilling machine to make holes at the center of the indentation on the anvil surface of the diamond anvil (the diameter of the diamond anvil surface used in the experiment is 400 μm, and the hole diameter of the hole is 300 μm), and the diameter of the hole is smaller than that of the diamond anvil. The indentation diameter of the anvil surface can be 3 / 4 of the indentation diameter of the anvil surface of the diamond anvil.

[0029] The third step: Mix diamond powder or cubic boron nitride powder or alumina powder with epoxy resin in a ratio of 4:1 by mass, grind evenly and fill in the holes ...

Embodiment 2

[0032] Example 2 Making electrodes on diamond anvil

[0033] The process of making electrodes on a diamond anvil can refer to the prior art: ZL200710055801.8, the name of the invention is "diamond anvil for in-situ measurement of electrical quantities and its manufacturing method". The only difference of the present invention is that the shape of the electrodes on the anvil surface of the diamond anvil is circular. The specific production steps are as follows.

[0034] Step 1: Soak the diamond anvil in a mixture of alcohol and acetone for 30 minutes to remove surface stains, and rinse with deionized water after taking it out.

[0035] The second step: on the surface of the two diamond anvils, a layer of metal molybdenum is respectively plated by magnetron sputtering as the electrode material.

[0036] Step 3: Take out the diamond anvil plated with metal molybdenum film, apply a layer of photoresist evenly on the surface of the two diamond anvils, and use the photoresist to c...

Embodiment 3

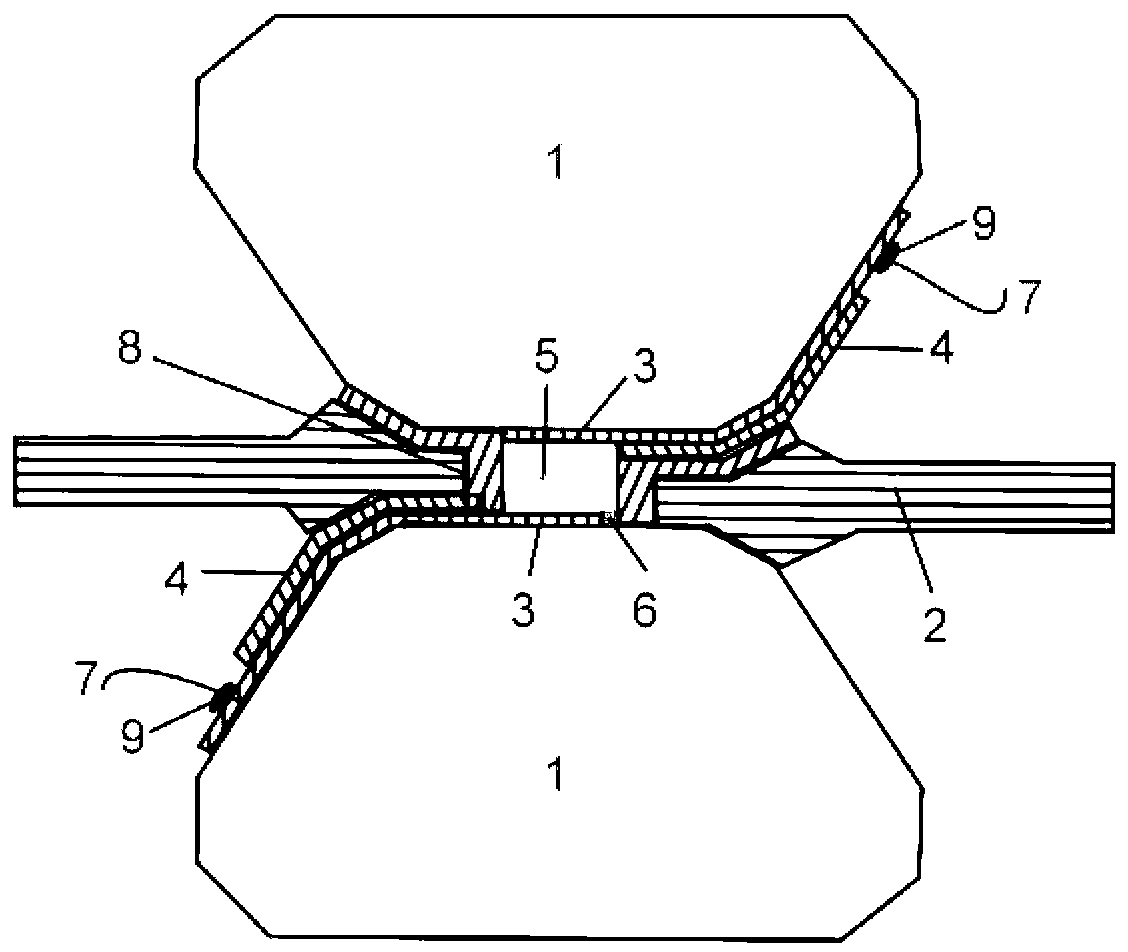

[0039] Example 3 Assembly of two diamond anvils with electrodes and composite insulating gaskets.

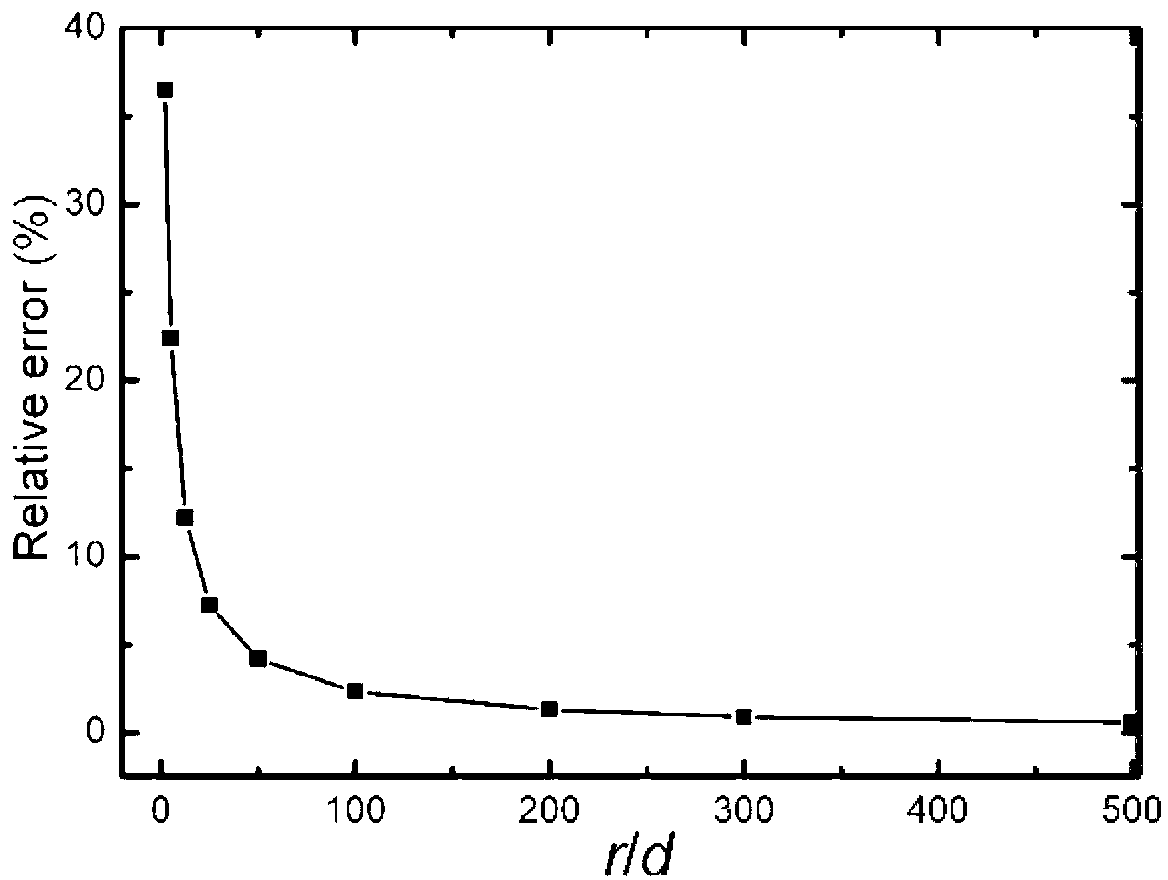

[0040] combine figure 2 The assembly in the measurement of in situ dielectric properties is illustrated. figure 2 Among them, 1 is a diamond anvil, 2 is a composite insulating gasket, 3 is a circular electrode, which is composed of a metal molybdenum film, 4 is an aluminum oxide film, 5 is a sample cavity, 6 is a ruby pressure mark, and 7 is an electrode lead, which can be It is a thin copper wire, 8 is an insulating layer, the insulating layer 8 is pressed on the composite insulating gasket 2, and the position is on the side wall of the sample chamber 5 and the chamfer of the corresponding diamond anvil 1. In the figure, the diagonal line from the lower left to the upper right Marked, the material of the insulating layer 8 can be a mixture of diamond powder and epoxy resin, or a mixture of cubic boron nitride powder and epoxy resin, or a mixture of alumina powder and epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com