Method for manufacturing space complicated curve surface core box mold

A core box mold and complex curved surface technology is applied in the field of mold manufacturing, which can solve the problems of batch production process constraints of ship brackets, serious mold making consumables, and low mold service life, saving wood consumption, simple production, and improving mold strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

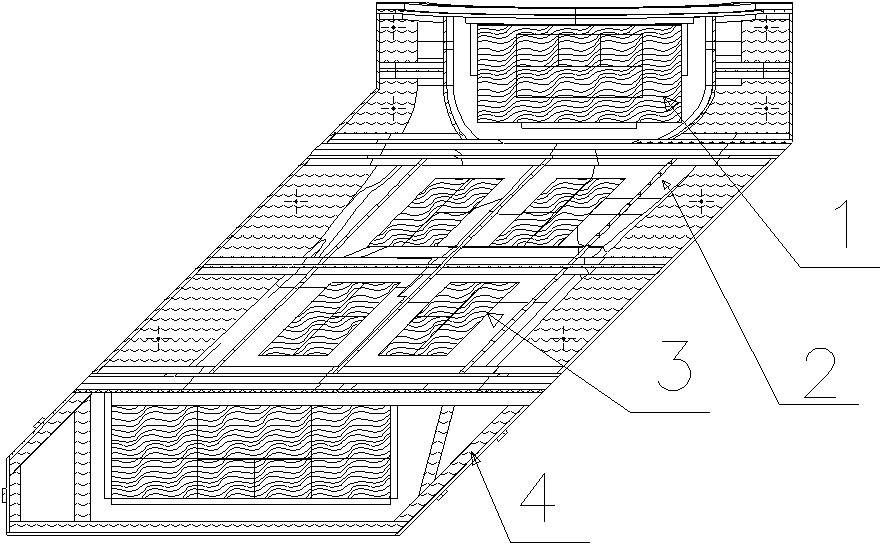

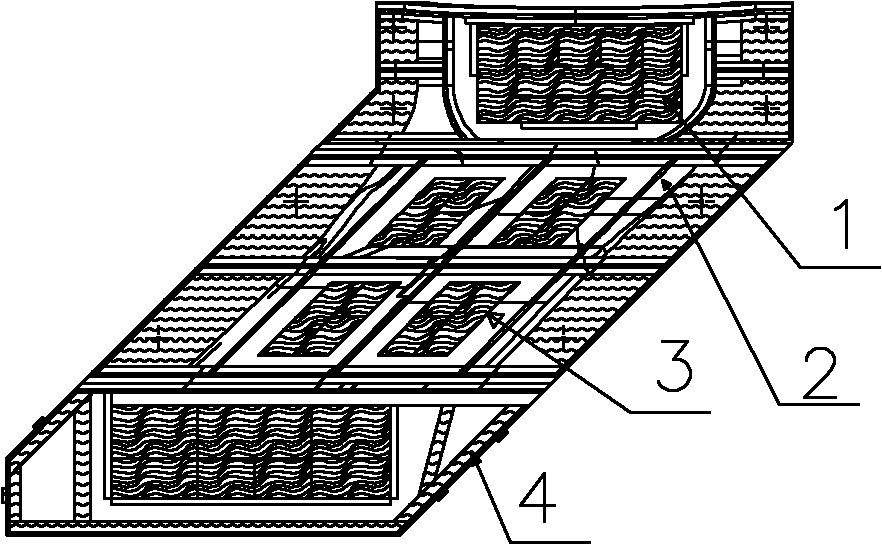

[0027] A method for manufacturing a core box mold with complex spatial surfaces, characterized in that: the method includes the following steps:

[0028] a. Material selection: Use wood to make the bracket mold body, and add a 20mm thick conformal steel frame outside the body for load-bearing reinforcement;

[0029] b. Establish the three-dimensional space model of the mold: use UG software, use the point-by-point grid surface method to model the three-dimensional space of the model, and then design a conformal steel frame around the model to ensure that the steel frame is completely consistent with the mold body of the bracket;

[0030] c. Make the main load-bearing steel frame: according to the size and shape of the model designed in the previous order, accurately weld the conformal steel frame;

[0031] d. Make the mold blank: use the welded main load-bearing steel frame to carry out segmental ring material, and each segment is divided into regional ring material, and when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com