Space camera reflecting mirror center support device

A central support and space camera technology, applied in installation, optics, instruments, etc., can solve the problems of poor axial and radial positioning between the mirror and the support structure, large adhesive area of the mirror, and poor surface deformation of the mirror, etc., to achieve Reduce assembly difficulty, ease assembly, and reduce assembly stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

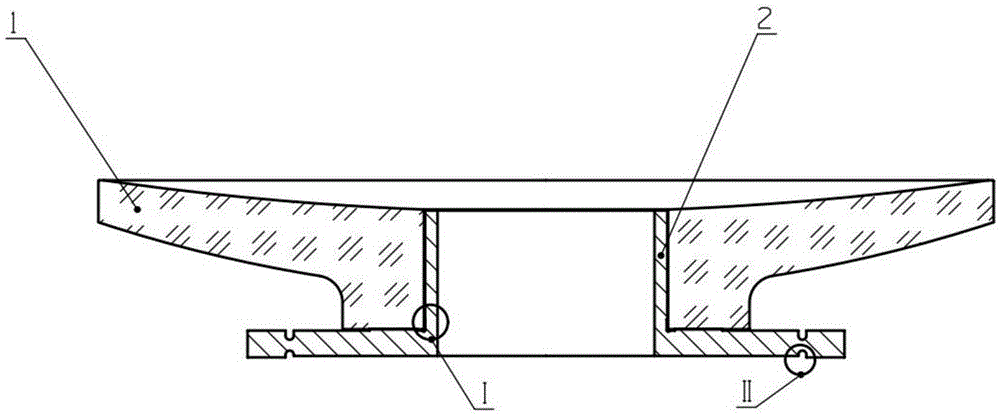

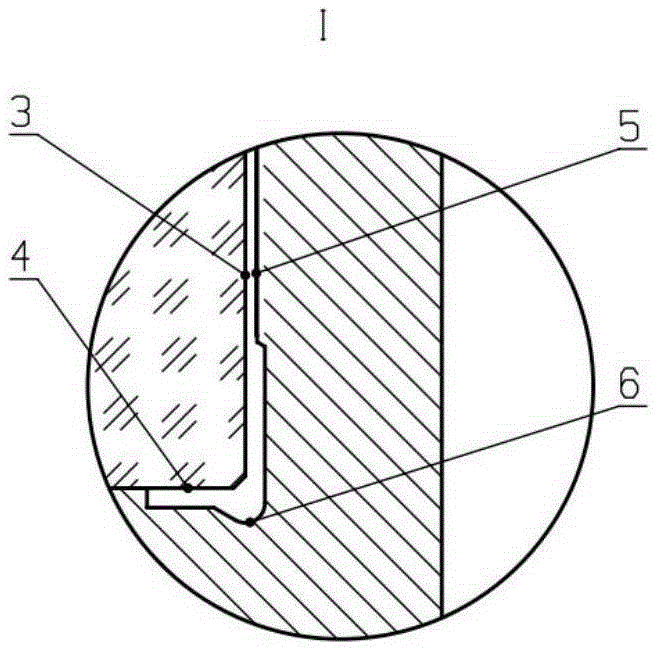

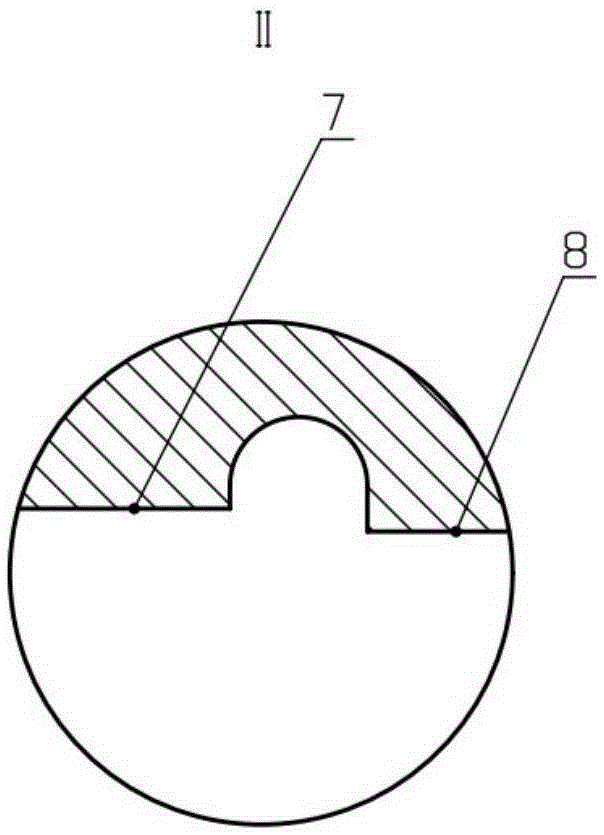

[0014] Specific implementation mode 1. Combination Figure 1 to Figure 5 To illustrate this embodiment, the central support device of the space camera mirror includes a flexible support structure, which is directly obtained by mechanical processing; the flexible support structure 2 includes a support structure and a 120° uniform The three flexible structures of the cloth are provided with a mandrel 11, an upper bottom surface boss 13, a glue injection groove 12 and a glue overflow groove 6 on the support structure; it is convenient for the overflow glue to flow during installation, and to prevent the glue from flowing into the bottom of the mirror 4; A plurality of glue injection grooves 12 are evenly distributed in the circumferential direction of the mandrel 11, and the bottom of the glue injection groove 12 is provided with an overflow glue groove 6; the inner ring 3 of the reflector is set on the outer ring 5 of the mandrel, and the bottom 4 of the reflector is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com