Buckling support roll and buckling support roll assembly machine

A technology for assembly machines and rollers, which is applied to assembly machines, rollers, conveyors, etc., can solve problems such as short service life, large shape and position deviation, and not very smooth, and achieve low processing costs, low equipment costs, and easy operation. The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

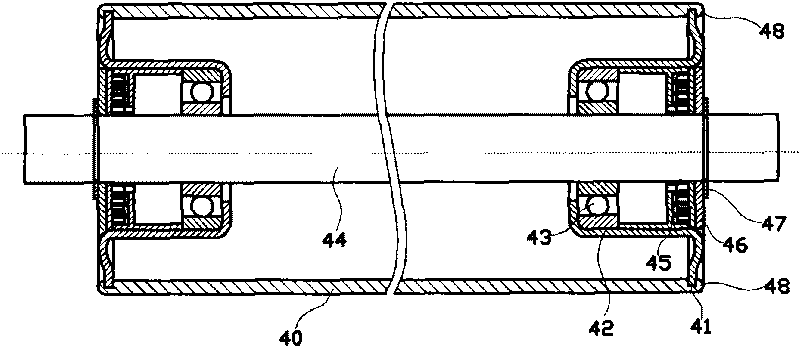

[0023] Figure 10 Among them, the crimping idler has a steel pipe 40, and the inner nozzles at both ends of the steel pipe have annular steps 41 respectively, and there are bearing cups 42 on the annular steps of the inner nozzles at both ends of the steel pipe, and there are bearings 43 in the bearing cups. Wear the idler shaft 44 whose axis is on the same line as the axis of the steel pipe, the sealing cover 45 of the bearing set on the idler shaft in the bearing cup, the baffle piece 46 and the retaining spring of the sealing cover on both sides of the idler shaft 47. There are inward flanges 48 for buckling the bearing cup at the pipe openings at both ends of the steel pipe.

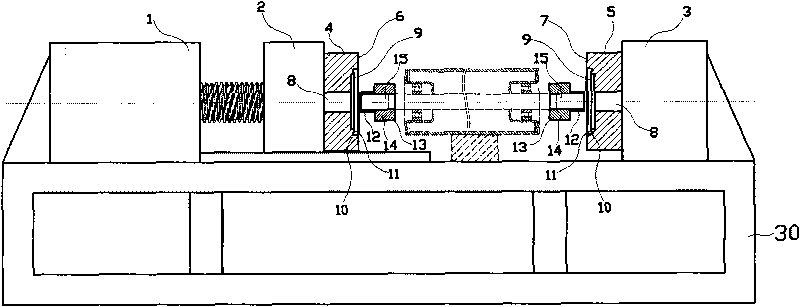

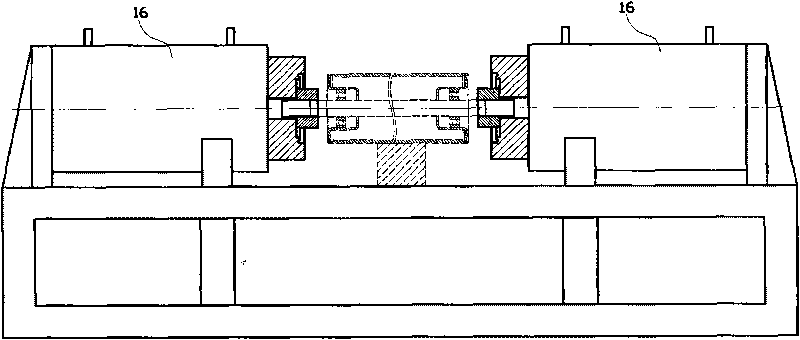

[0024] figure 1 Among them, the crimping idler roller assembly machine has a frame 30, and the crimping head driving device on the frame is a horizontal press machine 1 with a screw driving device. The crimping head 2 and the base 3 of the press machine are respectively connected with crimping dies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com